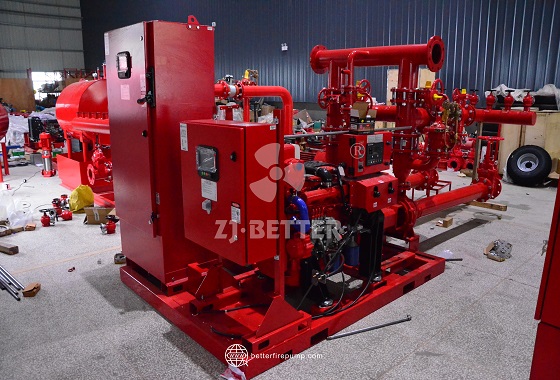

Diesel engine fire pump with high efficiency

Diesel engine fire pump is a common fire fighting equipment, especially suitable for use in places without electricity supply. The diesel engine fire pump uses a diesel engine as a power source to convert the work of the pump into hydraulic power to achieve a certain flow and pressure. It is mainly used in building fire protection, engineering fire protection, water source fire extinguishing and other fields.

The advantages of diesel engine fire pumps are wide application range, convenient use and high efficiency. It can start quickly and provide emergency fire protection in the external environment without electricity. The diesel engine fire pump can ensure that the water pump will not overheat during long-term operation through the diesel engine cooling system. Moreover, this type of fire pump can better store water resources and avoid disasters caused by insufficient water sources during fire fighting. In addition, the construction of diesel engine fire pump is simpler than traditional fire fighting equipment, and it is easier to maintain and maintain.