Horizontal Diesel Fire Pump Solution for Industrial Parks and Warehouses

The horizontal diesel fire pump system is suitable for large factories and logistics parks. It operates independently and provides efficient water supply, ensuring the continuous and stable operation of the fire protection system in a power outage environment.

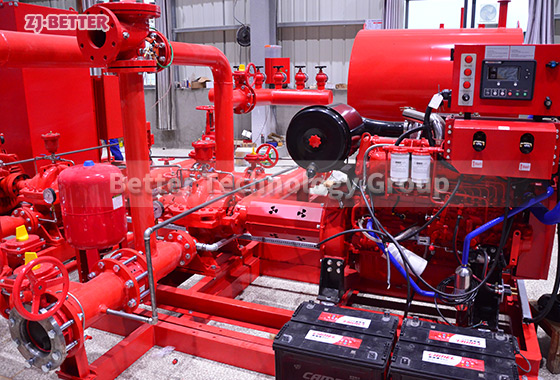

Under the current background of rapid industrialization and urbanization, key places such as large factories, storage and logistics parks, and comprehensive industrial bases are increasingly dependent on fire safety systems. As a key component of the entire fire protection system, the reliability, stability, and independent operation capability of the fire water supply system are directly related to the safety of personnel and property. In this high-intensity use and high-risk environment, the traditional electric fire pump system has certain limitations. Especially in the case of power outages, unstable power supply, or sudden disasters, electric-driven fire-fighting equipment may not start normally, seriously affecting the efficiency of emergency response. In contrast, the horizontal diesel-driven fire pump has become an indispensable and important fire-fighting equipment solution in large industrial facilities and logistics parks due to its strong independence, rapid start-up, and strong continuous water supply capacity. Horizontal diesel fire pumps are usually composed of high-performance industrial diesel engines, horizontal single-stage or multi-stage centrifugal pumps, heavy-duty bases, intelligent control cabinets, pressure-stabilizing tanks, cooling systems, fuel tanks, silencers, and other systems. They have complete integrated operation capabilities and can achieve automatic start-up and stable water supply under complete power outages or extreme working conditions to ensure the first-time fire extinguishing needs.

The diesel engine used in this type of equipment is usually a heavy-duty industrial power equipment with the characteristics of high output power, low fuel consumption, strong durability, fast start-up and short response time. In the event of a fire or emergency, the control system can receive a fire signal or water pressure signal, automatically start the diesel engine to drive the centrifugal pump, and achieve continuous water supply. The centrifugal pump part can use models with different flow and head parameters according to the needs of different sites. Most of them are made of high-strength cast iron or stainless steel, with high corrosion resistance and pressure resistance, and can meet the requirements of long-term operation. The pump body and the diesel engine are rigidly connected by a high-strength coupling, with high power transmission efficiency, good stability, and energy loss. In large factory areas, the fire protection system may be laid out with long-distance pipe networks, multi-point distributed sprinkler or fire hydrant systems, and the water supply flow and pressure requirements are very high. This horizontal diesel pump group can be fully met by configuring a large-flow pump type, dual pump switching or parallel operation scheme to ensure that the entire system has sufficient water supply and stable pressure.

In terms of control system, the whole set of horizontal diesel fire pump is equipped with a high-intelligence electric control cabinet, which has multiple start modes, including automatic, manual, electric start, remote start and other functions. The system has built-in fault self-checking, low oil pressure alarm, high temperature shutdown, start failure protection, remote signal input and output and other multiple protection mechanisms, which can realize all-weather monitoring of operation status and ensure operation safety. The control panel is clearly designed and easy to operate. Even non-professionals can quickly get started and complete the operation quickly in an emergency. In addition, the system can also be configured with a remote communication module as needed, and realize intelligent control such as pump group operation status data collection, alarm information push, and remote start and stop of equipment through the Internet of Things platform or the fire center remote monitoring system. It is suitable for access to modern smart factories or smart park management systems to improve overall management efficiency and emergency response capabilities.

From the perspective of installation structure, the overall layout of the horizontal diesel fire pump group is more in line with the space use logic of large factories and logistics parks. The equipment is installed in a public pump room or outdoor foundation platform, connected to the fire pipe network through a standardized interface, with a reasonable pipeline layout and a short construction period. The base of the equipment is reserved with lifting holes and forklift holes, which is convenient for on-site movement, hoisting and positioning, and is suitable for various ground foundation conditions. The pressure regulator tank is integrated on the base platform to ensure that the system pressure is maintained before the equipment is started, avoid false alarms or no-load start-up, and effectively improve the system response stability. The whole set of equipment can be equipped with auxiliary configurations such as rain cover, muffler, dust net, heating system, etc., so that it can still maintain reliable operation in special environments such as high temperature, high humidity, dust, high altitude, etc. For example, in metallurgical plants, logistics distribution storage parks, and petrochemical projects, this type of pump group has been operating for a long time in complex climates and variable working conditions, and still has excellent starting ability and stable output water pressure performance.

In terms of maintenance, the horizontal diesel fire pump also shows a high degree of humanization and ease of operation. The diesel engine part adopts a modular design, with centralized maintenance points, easy inspection and replacement of accessories. Daily maintenance only requires regular replacement of engine oil, fuel filter, air filter, and checking of battery voltage and water tank coolant to ensure that the equipment is in good condition. The operation record of the whole machine can be automatically generated through the control system or the Internet of Things platform to assist management personnel in formulating periodic maintenance plans, reduce labor costs, and increase the service life of equipment. In actual engineering projects, many fire contractors and property companies have given high praise to horizontal diesel fire pumps, believing that they are “strong independent operation capabilities, long maintenance cycles, stable performance, and rapid startup”, and are a highly reliable choice for dealing with sudden fires.

Overall, horizontal diesel fire pumps have great application advantages in large industrial areas, logistics parks, ports, energy projects, and other places that have extremely high requirements for water supply reliability and independence. It not only makes up for the water supply gap of electric fire pumps in power outage scenarios, but also has many technical advantages such as high-performance output, high-intelligence control, high environmental adaptability, and low maintenance costs. At a time when fire regulations are becoming increasingly stringent and the pace of project construction is accelerating, choosing a stable, mature, and efficient integrated diesel fire pump system will greatly enhance the integrity and emergency response capabilities of the project fire protection system, and provide strong technical support for safe production and asset protection. Therefore, this horizontal diesel pump set is not only a key fire protection equipment in the current project construction, but also the core force for upgrading and transforming the fire protection system in high-standard places in the future.