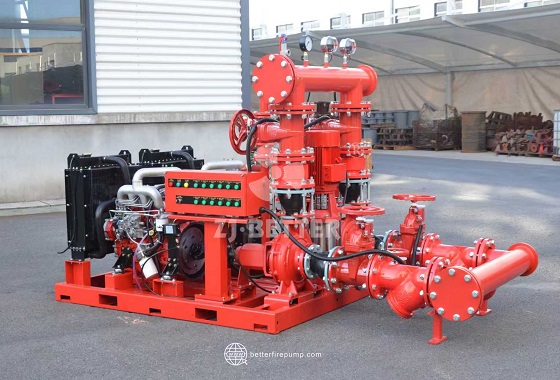

Fully Enclosed Diesel Fire Pump System for Continuous Water Supply in High-Risk Areas

The fully enclosed diesel fire pump system is independent of the power grid, ensuring continuous water supply in high-risk locations. It has the advantages of automatic start-up, intelligent control, high efficiency and durability.

The fully enclosed diesel fire pump system is a highly integrated emergency water supply solution designed for high-risk areas, especially for places where continuous power supply cannot be guaranteed, such as petrochemical plants, high-rise buildings, industrial parks, ports, airports, etc. Such places have very high requirements for the stability and independence of the fire protection system, and the diesel-driven fire pump system has become an important tool for dealing with sudden fires and emergencies due to its advantages such as no reliance on external power supply, rapid startup, and strong continuous water supply capacity. The system usually consists of a diesel engine, a centrifugal fire pump, a fuel tank, a cooling system, an automatic control cabinet, a silencer and a protective cover. All components are tightly integrated in a sturdy casing to ensure that the equipment can still operate efficiently in extreme environments.

One of the biggest advantages of this equipment is that it is completely independent of the power grid. As a power source, the diesel engine can operate independently without relying on the power grid. In many high-risk locations, especially those projects located in remote areas, the power grid may be unstable or completely unable to provide support. The diesel fire pump system is fuel-driven, ensuring that it can still start and provide continuous fire water supply in the event of a power outage or power grid interruption, ensuring that it is not restricted by the power system when a fire occurs, and providing sufficient water for fire fighting work in the first place. At the same time, the diesel engine itself has a high power output and strong starting torque, which can quickly start and maintain long-term high-load operation, ensuring long-term uninterrupted water supply.

In terms of performance, the fully enclosed diesel fire pump system is equipped with an efficient multi-stage centrifugal pump, which can adjust the flow and head as needed. The centrifugal pump design makes the water flow conversion efficiency higher, and can output a large flow and high head of water in a short time, meeting the fire fighting system’s requirements for fire fighting water pressure. The pump system is suitable for a variety of working conditions, whether it is a long-term low-flow stable pressure water supply or a large-flow high-pressure water supply, it can provide a stable water source. In addition, the pump body and pump shaft are made of high-strength cast iron or stainless steel, which is corrosion-resistant and high-pressure-resistant, and can maintain efficient and stable performance under long-term operation.

In terms of control, the diesel fire pump system is equipped with an intelligent control cabinet, which integrates multiple functions such as automatic start, manual start, remote control, and fault alarm. The control cabinet is equipped with sensors such as water flow, pump pressure, temperature, and oil pressure to monitor the working status and various operating data of the pump group in real time, ensuring that an alarm signal can be issued immediately when an abnormality occurs during the operation of the equipment to remind the operator to check. The intelligent control system also has a self-diagnosis function, which can automatically identify and shut down the equipment for protection when a fault occurs, avoiding the expansion of the fault or damage to the equipment. In an emergency, the equipment can be remotely controlled through a remote communication interface, allowing the operator to start and stop the equipment and troubleshoot the fault away from the site, greatly improving the flexibility of fire response and emergency response capabilities.

Another outstanding feature of the fully enclosed diesel fire pump system is its fully sealed structural design, which can effectively prevent the impact of the external environment on the equipment. In harsh industrial environments, equipment may encounter challenges such as dust, moisture, high temperature, and corrosive gases, especially in high-risk places such as chemical, mining, and offshore platforms. The protection capability of the equipment is crucial. The protective cover equipped with the equipment can not only effectively prevent dust, water vapor, chemicals, etc. from eroding the internal components, but also effectively reduce the operating noise. The silencer and sound insulation design enable the equipment to maintain a low noise level when operating at high load, which is suitable for working environments with strict requirements on noise. The equipment shell is made of high-strength steel plate or aluminum alloy material, which is corrosion-resistant, waterproof and fireproof, ensuring safe and stable operation under extreme weather conditions.

In terms of installation, the system is compactly designed, and all components are integrated in a protective cover, which is suitable for limited installation space. The diesel engine, pump body, fuel tank and other systems are connected to the pipeline system through standardized interfaces, which reduces the difficulty and time of on-site installation. The equipment base has been reinforced and has strong seismic resistance, which is suitable for installation and use in earthquake-prone areas or high-risk environments. The equipment can also be customized according to customer needs to meet the installation requirements of different sites, ensuring efficient and convenient installation and use in various buildings and places.

In terms of maintenance, the fully enclosed diesel fire pump system has low maintenance costs and a long service life. The equipment design takes into account the simplicity of daily maintenance, and all major maintenance and replacement points are concentrated in easily accessible locations, reducing the complexity of equipment inspection and maintenance. The diesel engine part is designed with an easily removable shell to facilitate the replacement of routine maintenance items such as engine oil, air filter, fuel filter, etc. The system’s built-in self-diagnosis function can help users grasp the operating status of the equipment in real time, discover potential problems in time, and avoid the equipment from failing to start at critical moments.

In summary, the fully enclosed diesel fire pump system has become an indispensable part of the fire protection system in modern high-risk places with its excellent independence, reliability and high efficiency. It can not only ensure stable fire water supply under power outages or extreme working conditions, but also maintain high efficiency and low maintenance working conditions in long-term operation. With the rapid development of industrialization and urbanization, this type of equipment will play an increasingly important role in future fire safety assurance. Whether in high-rise buildings, storage and logistics parks, petrochemical bases, or temporary construction sites, remote areas far away from the power grid, the fully enclosed diesel fire pump system can provide continuous and reliable support for various emergency fire protection systems.