Dual Power for Maximum Safety: Application Value of Diesel Fire Pumps in High-Risk Environments

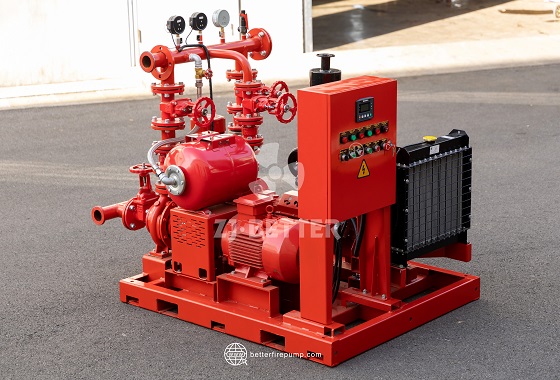

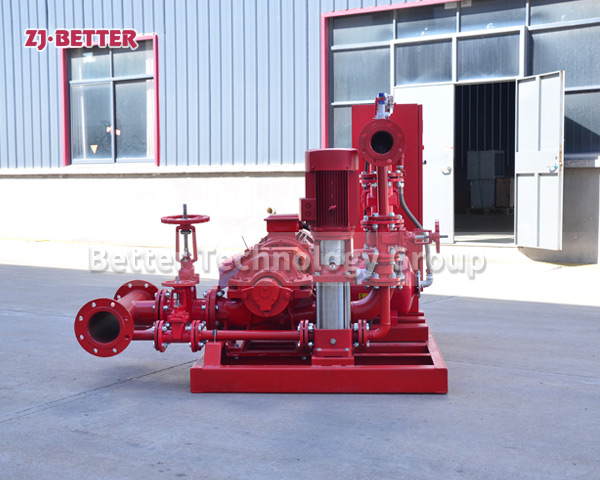

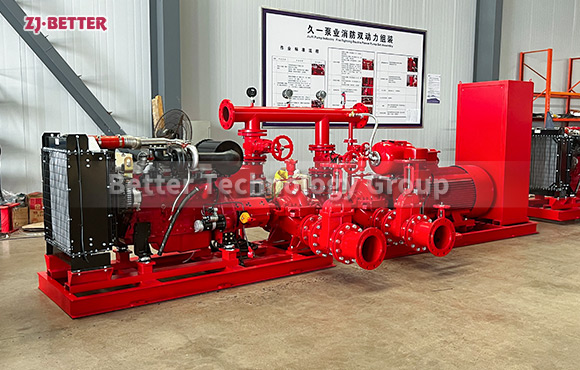

Diesel fire pumps offer dual power security, independent operation, and intelligent control, making them ideal for critical fire protection in petrochemical, tunnel, and high-rise applications.

In modern buildings, industrial facilities, petrochemical plants, and large-scale warehousing and logistics facilities, fire safety remains an absolute priority, especially in high-risk areas. Traditional single-power-source fire protection systems may lose their critical emergency response capabilities due to power outages, electrical faults, or power system failures. In such situations, diesel-powered fire pumps, with their dual fuel/electric backup, self-driven operation, rapid response, and unrestricted continuous operation, have increasingly become the core configuration of high-reliability fire protection systems. Diesel fire pumps do not rely on grid power supply. In the event of a fire or other emergency, even if the entire power supply system fails, the equipment can still start up and operate stably in the first instance, providing continuous and powerful water pressure support to the fire scene, significantly reducing the risk of fire spread caused by equipment failure. Its independence not only enhances the system’s fault tolerance but also meets the mandatory requirements for a secondary power source in international building fire safety standards. It is particularly suitable for scenarios with extremely high requirements for fire response time and reliability, such as petrochemical plants, mines, underground spaces, tunnels, and high-rise buildings. Additionally, modern diesel fire pump systems are equipped with intelligent control panels, enabling functions such as one-button startup, automatic detection, remote monitoring, and alarm linkage, further enhancing their intelligence and operational efficiency. The pump body is made of high-strength cast iron or stainless steel, ensuring durability, corrosion resistance, and high-pressure tolerance, suitable for various complex operating conditions. The diesel engine is sourced from leading international brands, ensuring sufficient power output, low fuel consumption, and rapid startup. The entire system has a compact structure and small footprint, making it suitable for installation in limited spaces. It also features excellent noise control and vibration suppression design, enhancing the safety and comfort of the operating environment. Especially in emergency situations, such as earthquakes, heavy rains, floods, or large-scale power outages, diesel fire pumps demonstrate significant advantages in emergency response capabilities, quickly taking over the primary water supply tasks of the fire protection system to ensure continuous and stable water pressure in critical areas, safeguarding personnel and property safety. In terms of energy efficiency and environmental protection, many new-generation diesel fire pumps comply with EU Stage V or US EPA Tier 4 emission standards, reducing particulate matter and carbon emissions while ensuring efficient operation and environmental responsibility. When used in conjunction with electric pump systems, diesel fire pumps can achieve primary/standby interchangeability and automatic switching without manual intervention, significantly enhancing the system’s overall redundancy and disaster resilience. Benefiting from advanced manufacturing processes, stringent quality inspection procedures, and international certifications (such as NFPA 20, UL, and FM), ZJ-BETTER brand diesel fire pumps are widely applied in overseas markets, including the Middle East, Southeast Asia, Africa, and Europe, and have garnered widespread recognition and high praise from customers. In summary, as a firefighting core equipment with a dual-drive (diesel and electric) backup mechanism, the diesel fire pump demonstrates irreplaceable strategic value in high-risk application environments and is an indispensable component of modern smart fire protection systems.