Automatic control requirements for diesel engine fire pumps and electric fire pumps

The diesel engine fire pump and the electric fire pump are “one standby and one use”. The control boxes of the diesel engine fire pump and the electric fire pump should be kept independent of each other, and the diesel engine fire pump must be used as the backup pump of the electric fire pump, and cannot be used as backup for each other.

The pump start signal in the fire extinguishing system is directly connected to the electric fire pump control box, and it is not suitable to be connected to the diesel engine fire pump control box at the same time. The pump start fault signal of the electric fire pump control box and the pump start signal in the fire extinguishing system are used as the automatic start pump start signal of the diesel engine fire pump control box, and the line is connected to the control box of the diesel engine fire pump. The pump start failure signal of the diesel engine fire pump control box received an alarm from the fire control center. After receiving the alarm, the authorized personnel rushed to the pump room to force the diesel pump to start in an emergency.

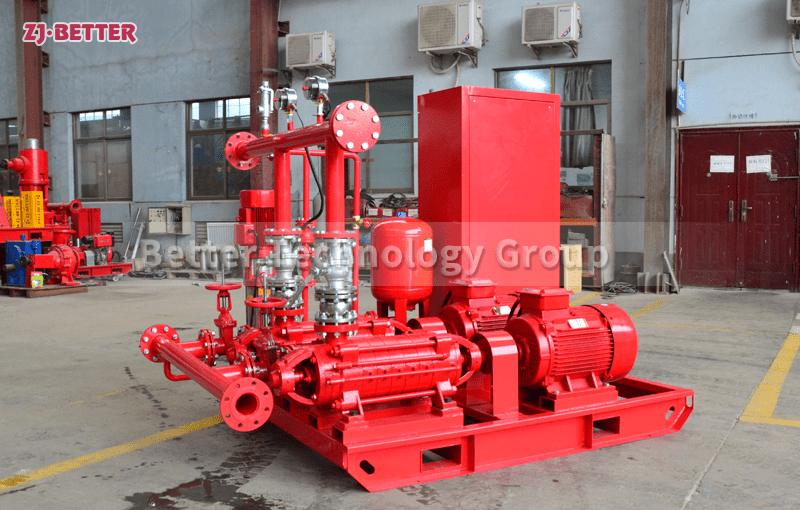

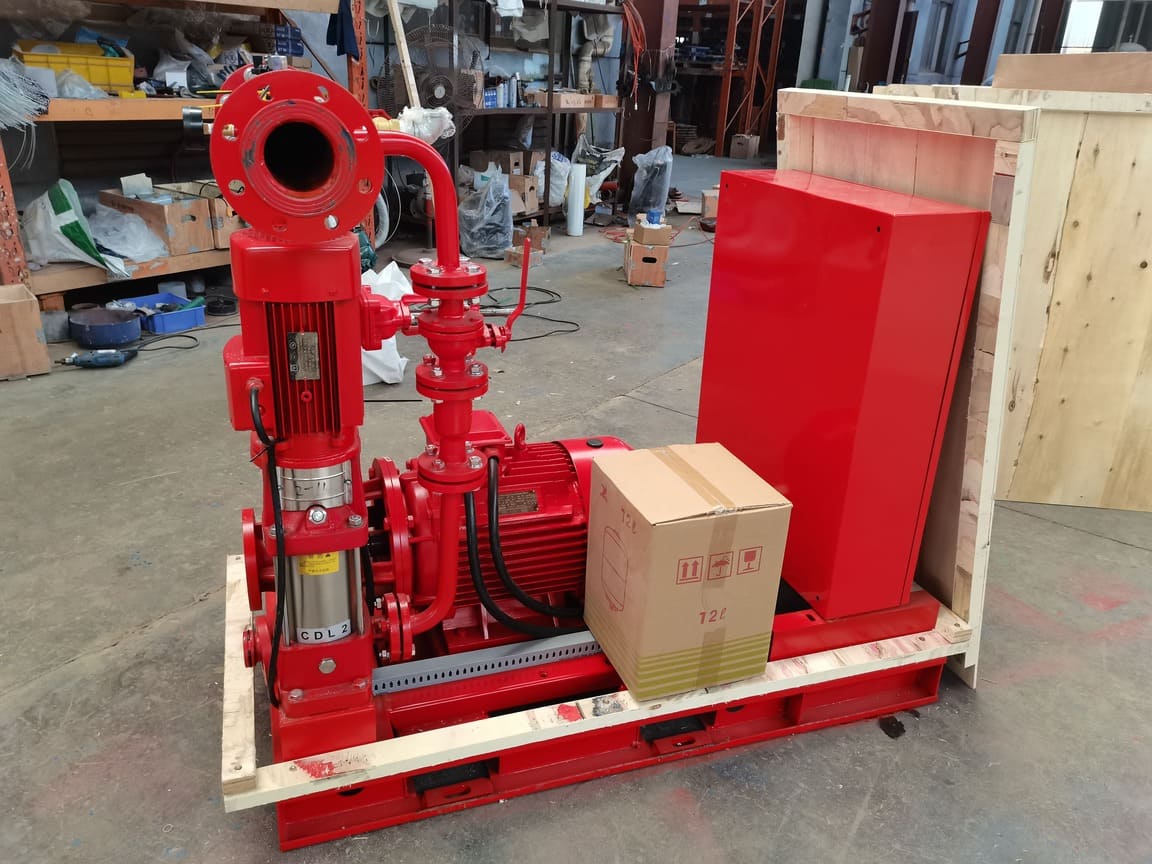

Electric fire pumps can supply fire water for general occasions. Diesel engine fire pumps are aimed at fire water supply for high-flow and high-lift occasions, and diesel engines have good starting characteristics, fast start-up speed, strong overload capacity, and can be used without running and standby all the time, saving energy. efficient. Diesel engine fire pumps have complete performance and a wide range of models. They can be used in single-stage single-suction pumps, multi-stage single-suction pumps, self-priming pumps, long-axis pumps, etc., and can also be used in combination and in parallel, with a wide range of flow and pressure. Diesel engine fire pumps are widely used for fire water supply in warehouses, docks, airports, petrochemical, power plants and other industrial and mining enterprises. Larger flow and head. The temperature of the conveying medium can reach 80°C.