Fire Diesel Power Unit Built for Harsh Environments: Reliable, Powerful, Long-Lasting

ZJ-BETTER diesel fire pump unit for extreme conditions delivers high torque, wide-temperature start, robust protection, and smart control—ideal for petrochemical plants, power stations, and critical emergency fire systems.

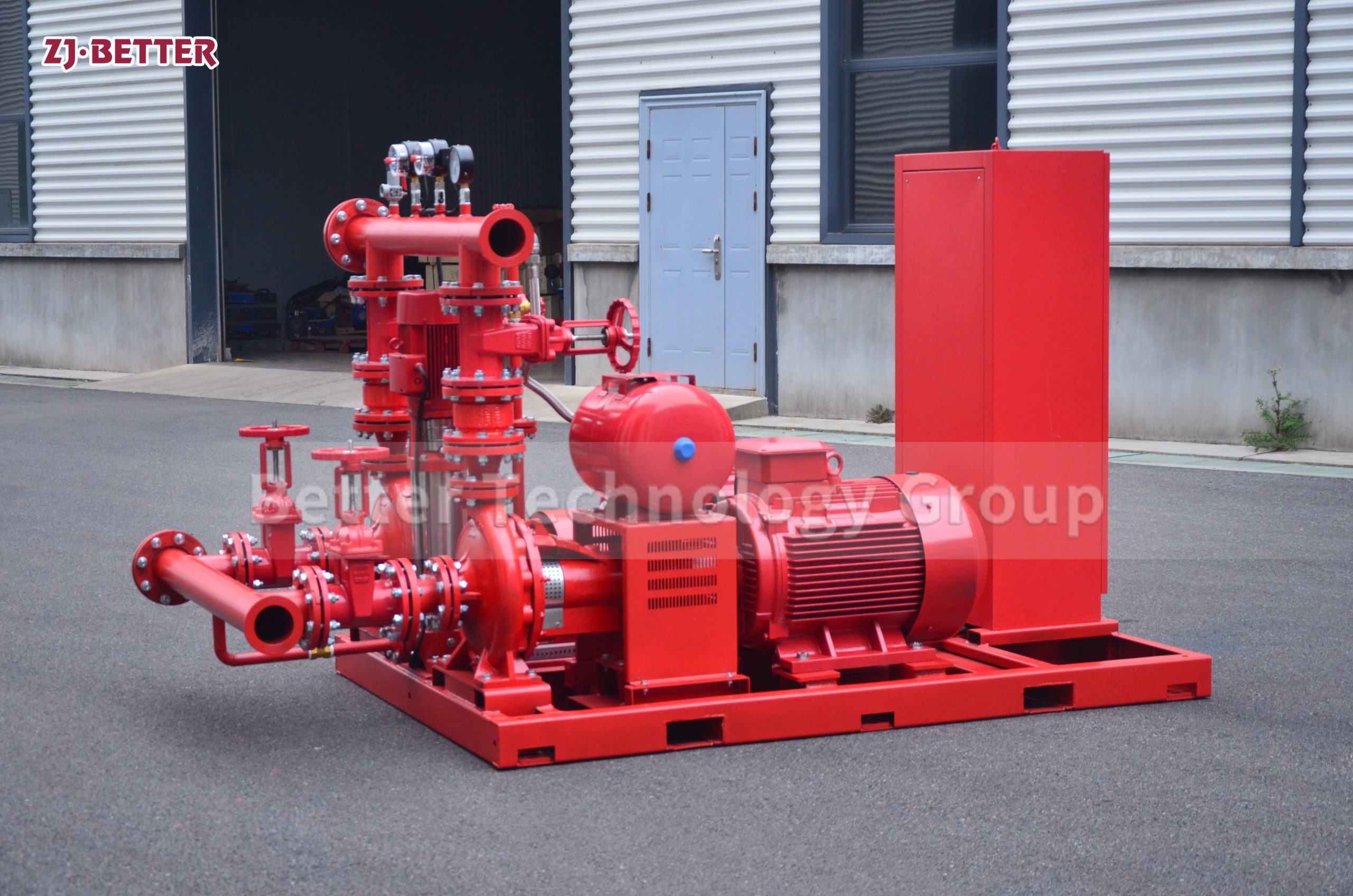

In modern fire protection systems, the stability and responsiveness of the power source determine the effectiveness of the entire setup. ZJ-BETTER’s diesel-driven fire pump unit is meticulously engineered for tough conditions and high-stress environments, offering a powerful combination of mechanical excellence and intelligent system integration. This makes it the go-to solution for industries with zero tolerance for failure.

At the heart of the unit lies a high-torque industrial-grade diesel engine, built with core components sourced from globally recognized manufacturers. Capable of reliable ignition across a wide temperature range (-20°C to +50°C), this engine performs equally well in scorching tropics and freezing highlands. It’s paired with a large-capacity fuel tank that allows uninterrupted operation for over 8 hours—ideal for long-duration emergency scenarios.

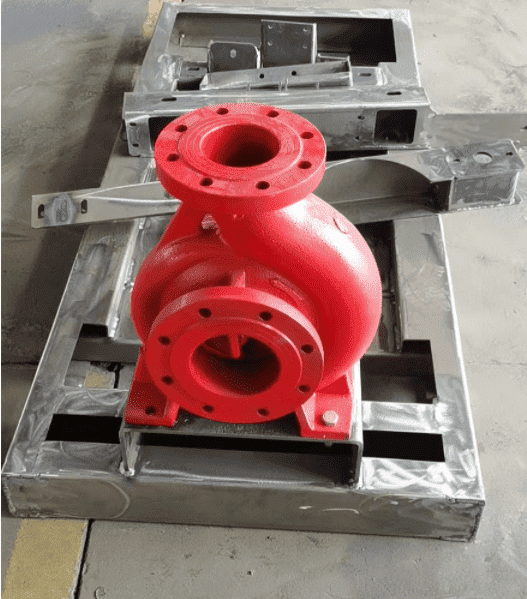

Engineered for endurance, the unit features a fully enclosed structure with advanced protection against dust, water, and vibration. A reinforced base and dual-layer anti-rust coating provide exceptional corrosion resistance, making it suitable for harsh chemical environments. It includes high-efficiency air and oil filtration systems, extending engine life and minimizing the need for maintenance, thereby lowering long-term operational costs.

Intelligence is embedded at every level. The unit comes with a smart multifunction control cabinet, monitoring vital parameters such as temperature, oil pressure, water level, and voltage in real time. With automatic start/stop and remote alert capabilities, it integrates seamlessly with centralized fire monitoring systems, enabling real-time diagnostics and smarter decision-making.

Customization is another hallmark of this diesel unit. Customers can tailor performance parameters including power range, flow capacity, ignition method (electric/manual), and synchronized control with fire pumps. The unit has been successfully deployed in petrochemical complexes, power plants, airport fire suppression systems, high-rise water reserves, and urban utility tunnels, consistently demonstrating exceptional reliability.

In summary, the ZJ-BETTER diesel fire pump unit is not just a piece of machinery—it is a mission-critical asset combining durability, smart control, and field-proven performance. It’s designed to protect not just infrastructure but the lives and assets that depend on uninterrupted fire safety in even the harshest environments.