Dual Advantage of Space Saving and Cost Reduction: Benefits of Integrated Fire Pump Units

The integrated fire pump unit features a compact design, space-saving structure, reduced installation and maintenance costs, and intelligent control. Ideal for urban buildings, industrial zones, and special environments, it’s the optimal choice for modern fire protection systems.

In the context of the growing pursuit of efficiency and intelligence in modern architecture and industry, the limitations of traditional fire pump systems—such as large footprints, lengthy construction periods, and complex installation and maintenance—have become increasingly apparent. Integrated fire pump units, however, offer a comprehensive solution through their modular, integrated, and high-efficiency design philosophy, providing users with space-saving, cost-optimized, and reliable performance. They are not only the result of technological innovation but also a key trend in modern fire protection system development.

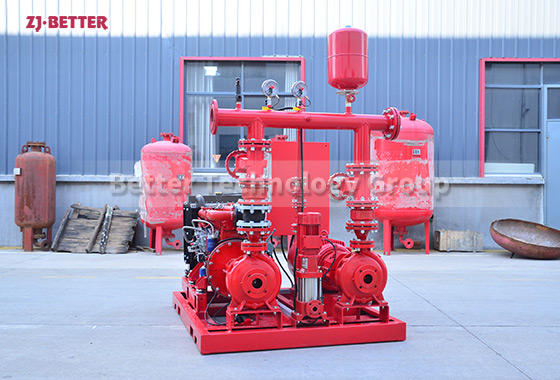

The most distinctive feature of integrated fire pump units is that all core functional components—including diesel engines, water pumps, control cabinets, fuel tanks, intake and exhaust systems, cooling systems, and starting batteries—are integrated onto a single steel structure base and pre-installed within a compact housing. This design effectively avoids the installation inconveniences caused by dispersed components during on-site construction and reduces additional construction costs resulting from space constraints. Additionally, the integrated structure significantly enhances system stability and operational efficiency.

The integrated fire pump unit is particularly suitable for locations with strict space requirements or high renovation difficulties, such as large commercial buildings, underground parking lots, factories, chemical industrial parks, and municipal pipeline networks. It has a small footprint, flexible installation options, and can be installed indoors or directly placed on the exterior of a building. Additionally, since the equipment has been pre-tested and fully tested at the factory, users only need to connect the pipes and power supply to quickly put it into use. This “plug-and-play” feature significantly reduces construction time and improves project delivery efficiency.

In terms of maintenance, integrated fire pump sets also offer significant advantages. Its internal layout is meticulously designed, with all inspection ports, oil lines, water lines, and electrical circuits arranged in a logical and accessible manner, facilitating routine inspections and maintenance by operators. Furthermore, the control system is centrally located within a protective cabinet, featuring intelligent functions such as automatic detection, self-diagnosis, and fault alarms, which greatly simplify post-installation maintenance tasks. In emergency situations, the system can respond swiftly to ensure the timely activation of fire protection functions, thereby enhancing overall safety standards.

From a cost perspective, the integrated design significantly reduces total project expenses. Traditional fire pump systems often require coordination among multiple contractors for equipment foundation work, component installation, and pipeline layout, leading to extended construction periods and complex coordination. In contrast, integrated pump sets are delivered as complete units from the factory, significantly reducing labor and time costs. Additionally, the integrated design reduces rework rates and maintenance costs caused by improper construction or incompatible interfaces, thereby improving investment efficiency.

It is worth noting that modern integrated fire pump units not only achieve high levels of mechanical integration but also incorporate intelligent control systems that integrate remote monitoring, data collection, historical logging, and alarm functions into daily management systems. Users can view real-time operational status, fault information, and startup records through a central control platform or mobile terminal, effectively enhancing the system’s digital management capabilities and providing a basis for subsequent data analysis and maintenance optimization.

Furthermore, the design of integrated fire pump units fully considers environmental protection and energy-saving requirements. Through optimized exhaust paths, low-noise mufflers, and intelligent start-stop controllers, the units operate at significantly reduced noise levels, making them suitable for areas with stringent noise control requirements. Additionally, the system features multi-mode control and energy-saving optimization functions, ensuring firefighting efficiency while minimizing unnecessary energy consumption, thereby providing robust support for green building standards.

As a highly efficient piece of equipment in modern fire protection engineering, the integrated fire pump system has been widely adopted in numerous countries and regions worldwide. Whether in new construction projects or retrofits of existing systems, it delivers tangible value to users through its flexible structure, outstanding performance, and significant cost-saving benefits. As urbanization accelerates and building intelligence levels rise, such equipment will play an increasingly vital role in the future.