The Ideal Choice for Power Outages: Performance of Self-Powered Diesel Fire Pumps in Critical Scenarios

Self-powered diesel fire pump operates independently without external electricity, ideal for remote areas, power outages, and high-risk sites. Ensures reliable emergency water supply, making it a vital component of modern fire protection systems.

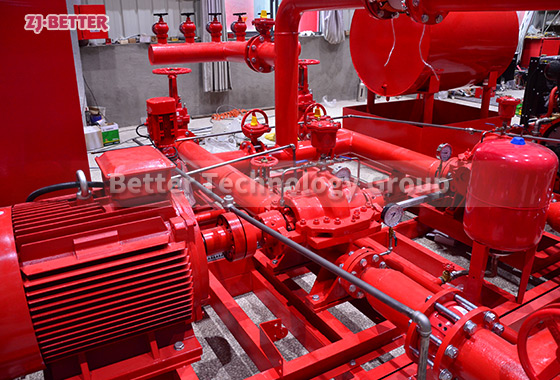

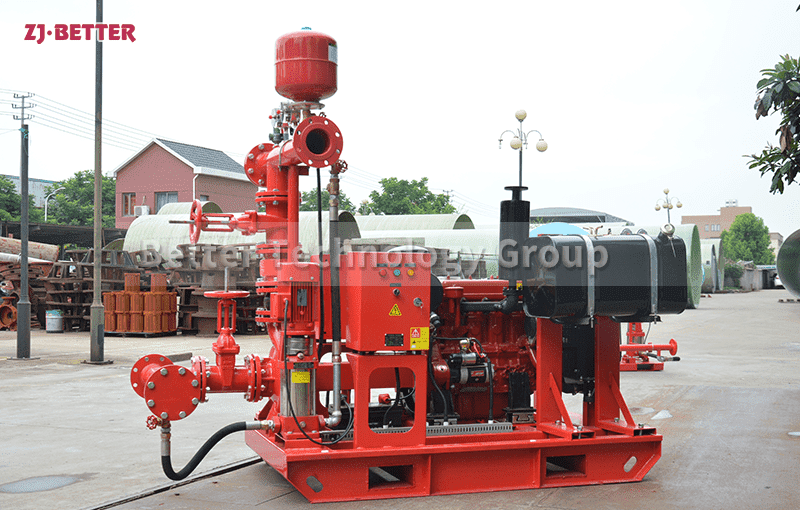

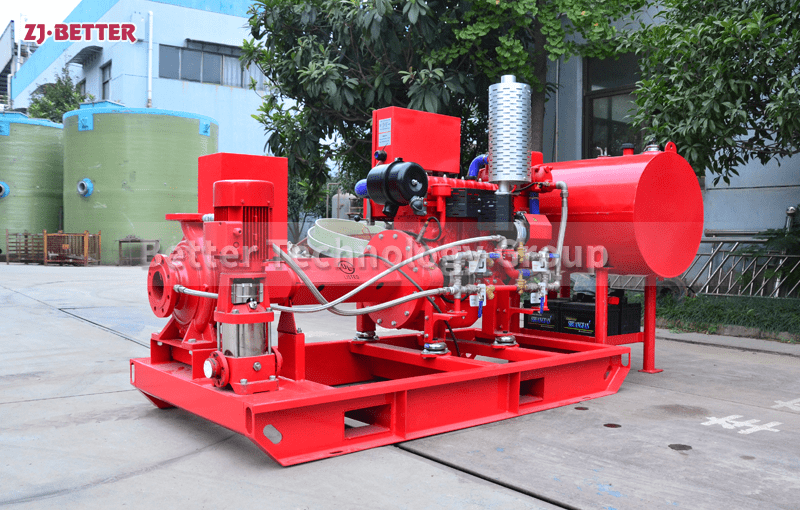

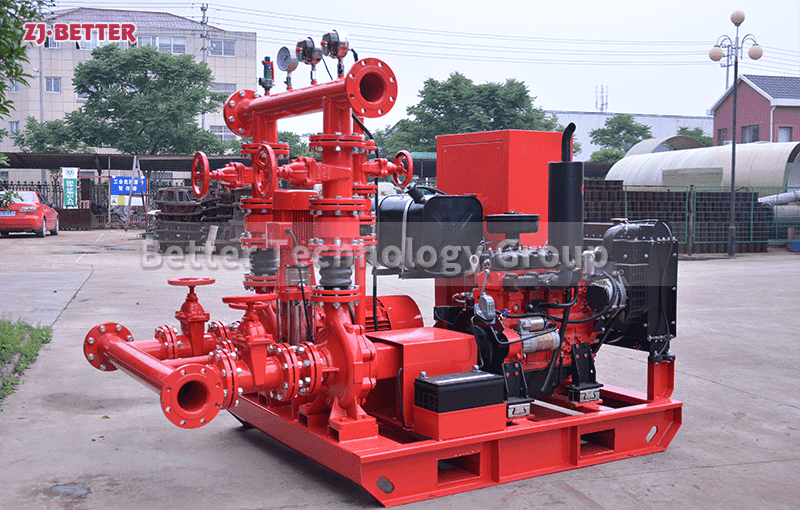

In the context of the continuous development of modern cities and industrial systems, the independence and reliability of fire safety assurance systems have become one of the key indicators to measure their effectiveness. Especially in the case of natural disasters, power failures or weak infrastructure in remote areas, traditional electric fire pumps face huge challenges of being unable to start or continue to operate normally. Therefore, diesel-driven fire pumps with self-powered energy have emerged as the times require, becoming an ideal choice for ensuring uninterrupted fire water supply in many key scenarios. The self-powered diesel fire pump is an efficient fire water supply equipment that integrates a diesel engine, a fire pump, an intelligent control system and a fuel system. It has the core ability to start and operate independently without an external power supply. It is mainly used in areas with unstable power supply, high-risk industrial sites, ports and terminals, petrochemicals, underground tunnels, remote villages, and emergency backup water source systems to ensure continuous and stable high-pressure fire water flow at critical moments, quickly suppress the spread of initial fires, and protect life and property. The diesel fire pump adopts a modular integrated layout in structural design. The unit is installed on a solid steel base. It is equipped with an efficient diesel engine and a professionally matched centrifugal fire pump, with strong power output and superior hydraulic performance. At the same time, the equipment is integrated with an intelligent electric control cabinet, which can realize manual, automatic and remote control start-up, ensuring automatic response start-up when the fire alarm signal is triggered or the main power supply fails, truly realizing 7×24 hours of emergency start-up without electricity. In the engine part, a high-performance diesel engine that meets international emission standards is selected, which has the characteristics of low fuel consumption, low vibration, low emissions and high stability, supports continuous operation for more than 2 to 6 hours, and can be equipped with an optional large fuel tank to extend the energy supply time; the unit is also equipped with an efficient water cooling system and an independent air-cooled radiator to ensure the stability of the equipment in high temperature or long-term operation environments, and avoid the risk of overheating and flameout. In terms of fire pumps, industrial-grade cast iron or stainless steel impellers are used, combined with advanced hydraulic model design, to achieve high head, large flow, low noise operation performance, to meet the diverse needs of different building structures, site scales and pipe network pressures. The actual operation test shows that this type of diesel fire pump can quickly increase the system water pressure at the rated speed, meet the national fire protection standards GB6245-2006 and NFPA20 and other international specifications, and show excellent fire protection performance in Class I and II high-rise buildings and key industrial sites. In order to ensure that the equipment starts correctly at the critical moment, diesel fire pumps are generally equipped with intelligent safety systems such as automatic battery charging system, fuel level monitoring, lubricating oil pressure alarm, high water temperature protection, oil alarm, and low fuel alarm, which greatly reduces the maintenance pressure of operators and improves the automation and safety of the overall system. In addition, some high-end configurations also support linkage control, and coordinate with electric fire pumps, water sprinkler systems, and alarm systems to form a complete intelligent fire control network, which enhances the overall efficiency of fire response and the systematic nature of command and dispatch. From the perspective of construction, the installation of diesel fire pumps is relatively flexible. The base of the equipment is equipped with reserved lifting holes and shock-absorbing pads to adapt to a variety of ground foundation conditions. There is no need for complex power pipeline access. After installation, it can be quickly debugged and put into use, which is particularly suitable for renovation projects or temporary emergency booster station construction. In addition, the equipment can also be customized according to customer needs, such as dual pump parallel system, automatic switching control system, sound insulation and noise reduction box, explosion-proof control panel, etc., to meet the diverse requirements of different countries, regions and industries. The operating performance under extreme working conditions is also one of the core competitiveness of diesel fire pumps. For example, in the case of sudden natural disasters such as typhoons and earthquakes that cause regional power outages, diesel fire pumps can still respond and start quickly to ensure the normal operation of the fire protection system and ensure timely control of the fire; in environments with complex geographical conditions such as deserts, plateaus, and mines, the equipment can also maintain reliable water supply capabilities with its strong self-priming ability and stable power output. Through a large number of engineering case verifications, such as the Middle East oil base, Southeast Asian chemical park, remote water conservancy station in Africa, and traffic tunnels in the western mountainous areas of my country, diesel-driven fire pumps have demonstrated their irreplaceable emergency water supply capabilities and long-term operating stability, becoming the “ballast stone” of fire protection system configuration in high-risk environments. At a time when global buildings are increasingly paying attention to the concepts of green, safe, and sustainable development, diesel fire pumps equipped with intelligent fuel management and low-emission technology are a cost-effective choice that takes into account both environmental protection and safety. In summary, the self-powered diesel fire pump, with its strong power output, independent energy supply guarantee, intelligent control response, multiple safety protections, flexible adaptation installation, and multi-scenario application capabilities, fully meets the extremely high requirements of modern buildings, industries, and public facilities for the stability and reliability of fire protection systems. As the “main force” in responding to emergencies such as power outages, it not only provides solid backing support for firefighting projects, but also further promotes the technological upgrading of emergency safety equipment and the direction of industry development.