Vertical Inline Fire Pump: A Space-Saving and Efficient Fire Protection Solution

In modern buildings and industrial facilities, efficient space utilization is crucial. Our Vertical Inline Fire Pump is specially designed to meet this need. With a vertical structure and in-line suction and discharge ports, it is easy to install directly into the pipeline without requiring a separate base, making it ideal for locations where floor space is limited or restricted.

This pump not only features a compact design but also offers high efficiency, strong head, and large flow rate. It can start quickly during emergencies and provide a stable and continuous water supply to the fire protection system. The motor is directly connected to the pump body, ensuring low vibration, smooth operation, and easy maintenance. It is an ideal solution for buildings, factories, warehouses, and other fire safety applications.

Whether for new construction or system upgrades, the Vertical Inline Fire Pump delivers a more reliable, efficient, and intelligent solution for your fire protection system.

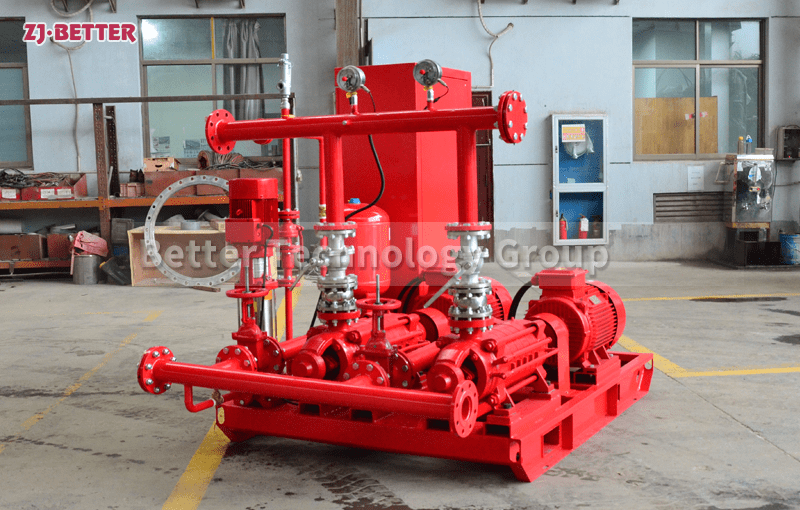

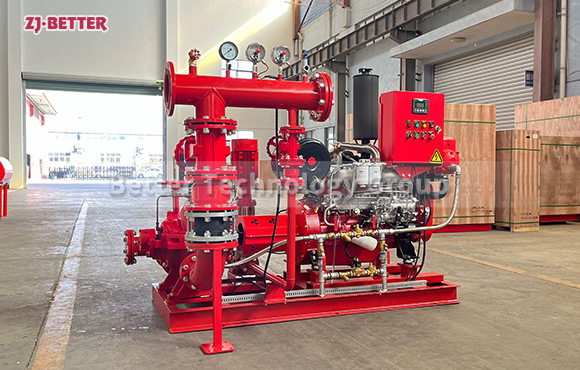

As a professional manufacturer of fire pump equipment, we are dedicated to developing and producing high-performance, safe, and intelligent fire pumps. Our product range includes electric fire pump sets, diesel engine fire pump units, dual power control systems, integrated fire pump stations, vertical inline pumps, and more. These products are widely applied in high-rise buildings, industrial plants, warehouses, petrochemical facilities, power stations, airports, and other mission-critical fire protection systems.

Our fire pump systems offer fast start-up, stable water supply, reliable operation, and easy maintenance. Designed in accordance with international fire protection standards, they feature high head, large flow capacity, strong durability, and corrosion resistance—capable of meeting the most demanding scenarios and emergency requirements.

With precise manufacturing processes and strict quality control, we ensure that every pump performs optimally in the most critical moments. We are committed to providing global clients with customized solutions and long-term technical support, helping to build smarter and more efficient fire protection systems to safeguard life and property.