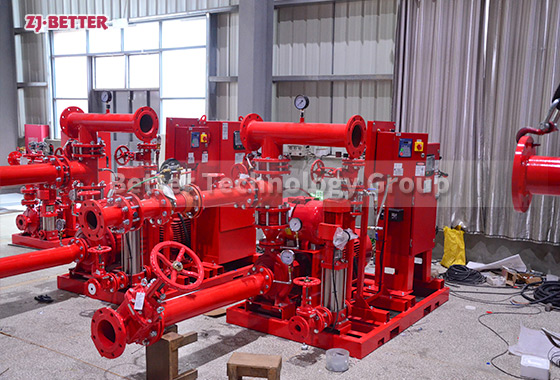

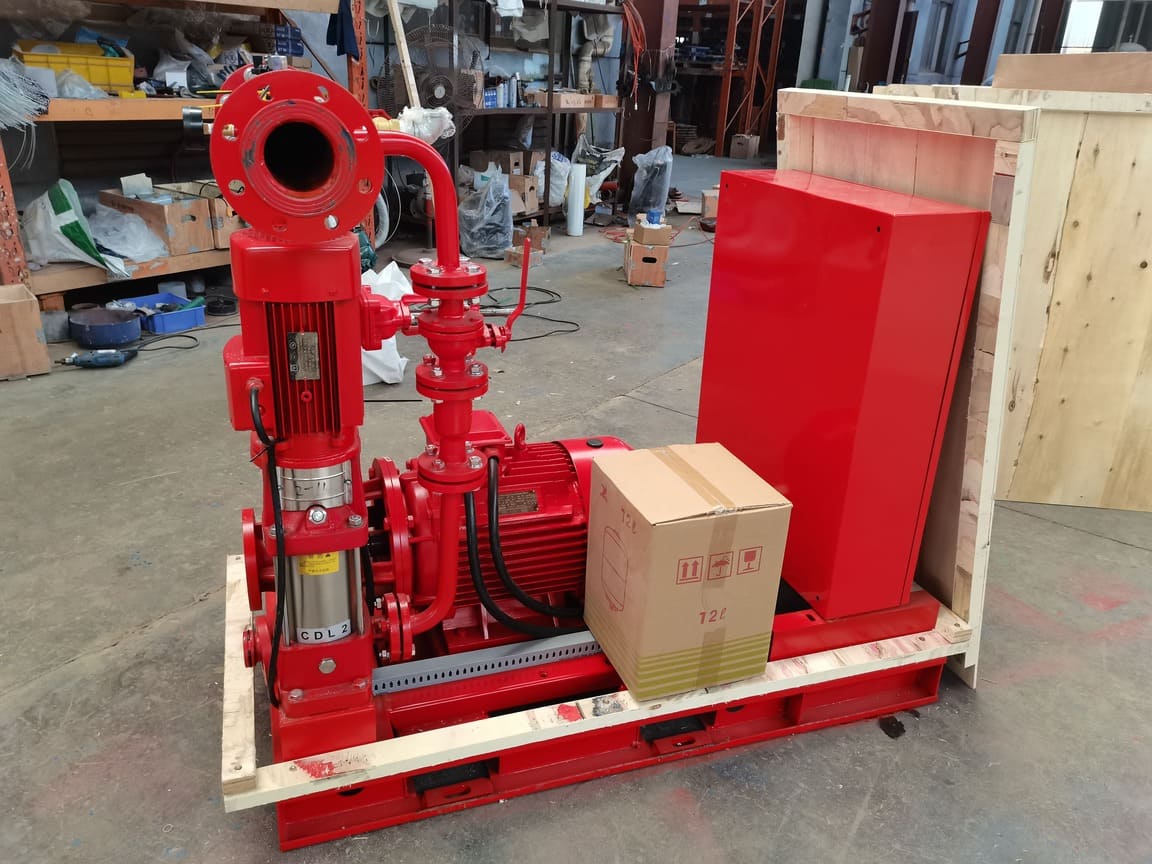

Fire Pump Unit with Integrated Control Panel for Automatic Start and Stable Pressure

The integrated control cabinet fire pump unit combines the fire pump, motor, and intelligent control system into a single unit. It features automatic start and stop, stable pressure output, multiple electrical protection features, and high reliability, making it suitable for building and industrial fire water supply systems, thus improving overall fire safety and response efficiency.

This integrated control cabinet fire pump unit is a highly reliable water supply equipment specifically designed for modern building fire protection systems and industrial fire engineering. It features a modular, integrated structure, combining the fire pump, drive motor, piping system, valve components, instrumentation, and intelligent control cabinet onto a single base. Through scientific layout and standardized design, it achieves rapid response, stable operation, and long-term reliable performance of the fire water supply system under emergency conditions. One of the core advantages of this fire pump unit is its highly integrated electrical control system. The control cabinet is designed to match the pump unit, allowing for real-time monitoring and precise control of motor operating status, system pressure changes, water source conditions, and start/stop logic. When the fire protection system receives a start signal or the pipeline pressure drops below the set value, the control system automatically completes the start-up process, avoiding delays caused by manual intervention and establishing a stable and effective fire water source in the early stages of a fire. The control cabinet uses industrial-grade electrical components and features multiple safety protection functions, including overload protection, phase loss protection, short circuit protection, and voltage anomaly protection, effectively improving the safety and stability of the entire fire pump unit in complex power environments and ensuring that the equipment does not fail due to electrical faults at critical moments. The fire pump body typically uses a high-efficiency centrifugal structure design. By optimizing the hydraulic model and impeller parameters, it effectively reduces hydraulic losses and improves overall operating efficiency while ensuring rated flow and rated head output. This allows the unit to maintain good performance even during long periods of standby or periodic testing. The pump body and key flow-through components are made of high-strength metal materials, possessing good wear resistance, corrosion resistance, and structural stability, making them suitable for various water quality conditions and meeting the fire water supply requirements of different application scenarios such as building fire protection, municipal fire protection, industrial plants, and warehousing and logistics. The drive motor selection fully considers the special characteristics of fire protection conditions, featuring high starting torque, stable operation, and reasonable temperature rise control. It can maintain reliable output under frequent start/stop or emergency start conditions, forming a good match with the fire pump, thus avoiding unstable water supply pressure caused by insufficient power or speed fluctuations. The entire fire pump unit is designed with practicality and reliability in mind, featuring a well-designed piping system with rationally arranged inlet and outlet pipes, complete with valves, check valves, pressure gauges, and exhaust components. This facilitates rapid pressure build-up during system startup, reduces water hammer impact on the piping and pump body, and extends the overall service life of the equipment. The integrated control cabinet fire pump unit also boasts excellent automation and compatibility in practical applications. It can be integrated into fire linkage systems according to project requirements, enabling coordinated operation with alarm devices, sprinkler systems, and fire hydrant systems, making fire water supply more intelligent and efficient. Before leaving the factory, the unit undergoes rigorous performance testing and operational debugging, including flow rate testing, head testing, sealing testing, and electrical control function verification, ensuring that each unit can be quickly installed and put into use upon delivery to the site, reducing on-site commissioning time and improving overall project delivery efficiency. From a maintenance perspective, this type of fire pump unit adopts a complete and standardized design with a clear structure and ample maintenance space, making daily inspections and regular maintenance more convenient. This helps reduce long-term operation and maintenance costs and ensures that the fire protection system remains in a usable state. Under the design philosophy of prioritizing both energy efficiency and reliability, this integrated control cabinet fire pump unit not only meets the performance and safety requirements of current fire protection regulations but also demonstrates significant advantages in stability, response speed, and system integrity. It is an indispensable core fire water supply equipment in high-rise buildings, commercial complexes, industrial plants, and various key fire protection areas. Through continuous, stable, and controllable pressure output, it provides a solid and reliable water source guarantee for the fire protection system, thereby gaining valuable time for personnel evacuation and fire control in the event of a fire, comprehensively improving fire safety levels.