High-Head Fire Pump for Diverse Applications: The Perfect Balance of Performance and Reliability

High-lift fire pumps possess powerful high-pressure water supply capabilities and excellent operational stability, specifically designed for high-rise buildings, industrial facilities, and long-distance water transmission systems. Their high-efficiency impeller structure, corrosion-resistant materials, and intelligent control system ensure a continuous and stable fire water supply. Suitable for both electric and diesel drive modes, they are reliable in operation and easy to maintain, making them an ideal choice for ensuring fire safety.

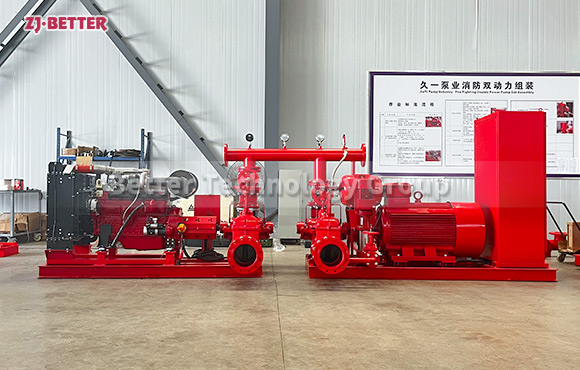

High-lift fire pumps are high-performance devices specifically designed for high-rise buildings, industrial facilities, large storage areas, and long-distance water supply and fire protection systems. With their excellent head capacity, stable pressure output, and highly efficient hydraulic structure design, they have become an indispensable key component in modern fire protection systems. The core design principle of high-lift fire pumps lies in achieving a perfect balance between high-pressure delivery and high-efficiency operation. They typically employ a single-stage or multi-stage centrifugal structure, effectively increasing water flow velocity and reducing energy loss through optimized impeller shape, pump chamber flow channels, and sealing systems, thereby ensuring continuous and stable water pressure output even under complex operating conditions. Fire protection systems require extremely high immediacy and reliability of water supply in emergencies, and high-lift fire pumps are designed for this purpose. They can start up and reach rated flow in a very short time, ensuring that fire sprinkler systems, fire hydrant systems, and other fire extinguishing devices can be quickly put into operation. They feature a compact structure, high transmission efficiency, and can be driven by either an electric motor or a diesel engine, allowing for flexible configuration based on site requirements to meet fire protection needs under different power supply conditions. In high-rise buildings, the head of conventional fire pumps often fails to meet the pressure requirements of top-floor sprinklers or elevated water tanks. High-lift fire pumps, however, utilize specialized hydraulic design and high-strength materials to maintain stable output under high-pressure operating conditions. This not only enhances the overall safety of the system but also reduces the complexity of multi-stage pump series connections, significantly lowering system maintenance costs. Structurally, high-lift fire pumps typically employ a high-efficiency closed impeller and wear-resistant volute design. The internal hydraulic channels are precisely calculated and machined to ensure smoother fluid flow within the pump body, effectively reducing hydraulic losses and cavitation risks. The shaft sealing system utilizes advanced mechanical seal technology, offering excellent temperature resistance, pressure resistance, and leak-proof performance. Even under prolonged high-intensity operation, reliable sealing is maintained without leakage or performance degradation. The pump body and base are constructed from high-strength cast iron or alloy steel, providing excellent overall shock resistance and corrosion resistance, enabling them to adapt to harsh installation environments and complex firefighting conditions. The drive unit of the high-lift fire pump is the power source for its stable operation. Electric motor-driven models feature rapid start-up, low noise, and smooth operation, making them suitable for buildings with a stable power supply. Diesel engine-driven models provide reliable backup power in the event of power failure or outage, ensuring continuous water supply to the fire protection system in any emergency. This flexibility in dual-power configuration makes high-lift fire pumps an ideal choice for fire protection systems in industrial areas, oil depots, ports, and remote locations. In terms of performance, high-lift fire pumps offer the dual advantages of high efficiency and low energy consumption. Their flow rate can be customized according to system design, ranging from tens to hundreds of cubic meters per hour, with a head reaching hundreds of meters, fully meeting the water supply needs of high-rise buildings and long-distance applications. The high-efficiency impeller design ensures stable water output, reduces pressure fluctuations, and makes the sprinkler system’s spray effect more uniform and reliable. Simultaneously, the pump’s efficiency curve is wide, adapting to different flow rate changes without significant energy consumption increase, resulting in extremely high operating economics. The control system of high-lift fire pumps also embodies a combination of intelligence and safety. The accompanying control cabinet enables automatic start/stop, pressure monitoring, flow control, temperature and current protection, and other functions, ensuring stable operation of the pump unit even in unattended conditions. When the system pressure drops to the set value, the pump automatically starts; when the pressure recovers, it automatically stops, effectively avoiding energy waste and mechanical wear caused by frequent start/stop cycles. Furthermore, the control system features manual and automatic dual-mode switching, facilitating manual intervention in emergencies and improving fire emergency response speed. In terms of manufacturing processes, the high-lift fire pump employs precision casting and CNC machining, ensuring the dimensional accuracy and surface finish of key components, thereby improving overall hydraulic performance. Rigorous dynamic balancing and pressure testing ensure stable and reliable performance before leaving the factory. All pumps undergo full-performance testing before leaving the factory, including flow rate, head, efficiency, and vibration/noise testing, ensuring that each pump meets design specifications in actual use. Simultaneously, the coating process uses an epoxy resin anti-corrosion coating, which not only enhances the appearance but also significantly improves the pump body’s corrosion resistance and extends its service life. The high-lift fire pump has extremely high adaptability in various application fields. In addition to conventional building fire protection systems, high-lift fire pumps are widely used in petrochemical plants, power plants, airports, docks, underground facilities, tunnels, and large-scale warehousing and logistics centers. For these locations, any water supply interruption can pose a significant safety risk, and high-lift fire pumps, with their high-pressure output and long-term stable operation, can provide a continuous and sufficient water supply. In the oil and gas industry and chemical plants, their high-temperature and corrosion-resistant design is particularly important, enabling the safe delivery of fire water containing trace amounts of chemicals or high-temperature media, ensuring efficient system operation even in extreme environments. Maintenance of high-lift fire pumps is very simple; routine checks only require checking the sealing system, lubrication status, and pressure parameters. Due to the use of high-quality bearings and seals, they have a long service life, requiring almost no frequent component replacements, significantly reducing later maintenance costs. The pump body is easy to disassemble and assemble, with ample maintenance space, allowing operators to quickly clean, inspect, and replace parts, minimizing downtime. Furthermore, these pumps can be networked with automatic monitoring systems to achieve remote monitoring and status alarms, allowing managers to monitor equipment operation at any time, thereby preventing malfunctions and improving overall system reliability. In summary, high-lift fire pumps, with their numerous advantages including high lift, high efficiency, low noise, low energy consumption, compact structure, stable operation, and intelligent control, have become one of the most representative water supply devices in modern building and industrial fire protection systems. They not only meet stringent fire water supply requirements but have also gained widespread recognition for their excellent engineering adaptability and long-term stability. Whether at the top of a super high-rise building or in industrial sites requiring long-distance water delivery, high-lift fire pumps provide the most reliable water supply guarantee with powerful performance and precise control, making them crucial equipment for protecting life and property.