Design Advantages and Engineering Adaptability of Open-Frame Diesel Fire Pump Units

High-performance fire pumps provide stable and reliable fire water supply solutions for various buildings and industrial facilities. They have the advantages of strong head, high flow rate, durable structure and intelligent control. They are suitable for harsh environments and long-term continuous operation, helping to improve the safety and emergency response capabilities of the overall fire protection system.

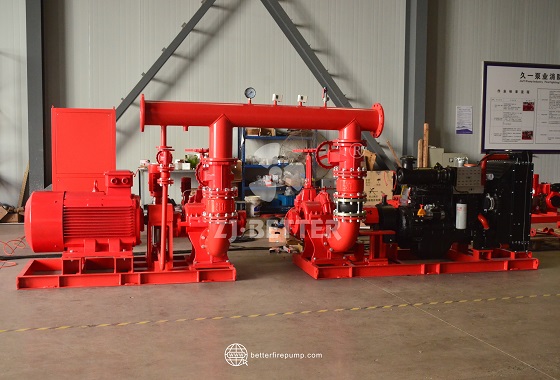

Open-structure diesel fire pump sets, as a key water supply device widely used in modern fire protection systems, have gained widespread application in industrial, commercial, municipal, and special scenarios due to their high efficiency, stability, ease of maintenance, and flexible installation. Their design philosophy revolves around reliability, practicality, and engineering adaptability. By optimizing the structural layout, power system, control system, and piping system, they achieve continuous and stable high-flow water supply output, providing strong safety guarantees for various fire protection projects. The core feature of open-structure diesel fire pump sets lies in their overall open-frame unit layout, which clearly distributes all components, including the diesel engine, water pump, control cabinet, coupling, fuel system, cooling system, exhaust system, and base structure, facilitating installation and maintenance. It also reduces heat dissipation limitations caused by enclosed enclosures, allowing the unit to maintain good cooling performance even under long-term continuous operation. The open structure not only improves the unit’s thermal management efficiency but also significantly reduces temperature rise problems caused by limited space and insufficient ventilation, thus ensuring stable power output. Furthermore, the open design makes the unit easier to transport, hoist, and install on-site, allowing for flexible configuration of piping direction and foundation structure to meet the personalized needs of different engineering environments. The dynamic power unit utilizes a high-performance diesel engine as its drive source, boasting advantages such as high torque, rapid start-up, excellent fuel economy, and stable operation. In emergency situations, it can quickly reach rated speed and drive the fire pump to achieve high-flow output. The diesel engine possesses strong environmental resilience; its performance is independent of external power supply, allowing it to operate independently even in the event of sudden power outages, severe weather, or disasters, providing a reliable water source for the fire protection system. The open structural layout makes maintenance points for the diesel engine clearly visible. These include the oil filter, air filter, fuel filter, water pump coupling, cooling water pipes, and belt tensioning points, all easily accessible from the outside, significantly improving maintenance efficiency and reducing unit downtime. The water pump section typically employs horizontal end-suction pumps, single-stage centrifugal fire pumps, or double-suction pumps. Different models with varying flow rates, head, and pressure ratings can be configured according to project requirements to ensure compliance with fire protection system specifications. Its internal components utilize corrosion-resistant materials and a high-strength impeller structure, ensuring long-term stable operation even under high-pressure water flow. The pump body and diesel engine are connected via a high-strength, flexible coupling, which effectively reduces vibration and impact, extending the life of bearings and sealing components. Another advantage of the open-type diesel fire pump set is its optional fully automatic control system. The control cabinet typically integrates intelligent monitoring, automatic start/stop, remote signal output, and data recording functions, enabling real-time monitoring of diesel engine speed, oil pressure, water temperature, battery voltage, fuel status, and pump pressure. It provides fault alarms, interlock protection, and automatic switching, making the unit’s operation safer and more intelligent. The control system also reserves a fire linkage interface, allowing for automatic startup when the fire pipeline pressure drops, providing rapid response in emergency scenarios and avoiding delays due to manual intervention. In terms of engineering adaptability, the open-type diesel fire pump set can flexibly adapt to various installation environments, including fire pump rooms, basements, semi-open factory areas, and outdoor locations. Its base uses a high-strength steel welded structure, possessing excellent seismic resistance and load-bearing capacity, and its size and layout can be customized according to project requirements. The overall layout of the unit is compact yet not crowded, reserving ample space for pipeline connections, system integration, and foundation construction, reducing engineering difficulty. The piping system supports flexible on-site layout, including water outlet direction, suction inlet location, oil return pipe arrangement, and cooling water discharge, all of which can be configured according to design conditions. This makes it particularly suitable for projects with complex space requirements or limited installation conditions. The cooling system typically employs water tank cooling, heat exchanger cooling, or forced air cooling. The open structure ensures smooth airflow, preventing temperature buildup and improving the stability of the unit during long-term operation. The exhaust system can be extended with additional piping, silencers added, or routed outdoors as required by the project, ensuring air quality in the fire pump room and reducing noise impact on the surrounding environment. The open-type diesel fire pump set also excels in durability. The equipment uses high-temperature resistant and corrosion-resistant structural materials, adapting to long-term operation and harsh environments such as high temperature, high humidity, high dust, and salt spray environments in coastal areas. The base painting process enhances rust prevention, while the open structure avoids water and dust accumulation within the enclosed enclosure, reducing the risk of equipment corrosion from the source and extending its service life. Open-type units also meet various international and engineering standards, including common hydraulic performance standards, automatic control standards, and emergency water supply standards for fire protection systems, making them suitable for a variety of applications such as high-rise buildings, factories, warehousing centers, petrochemical bases, municipal engineering, airports, docks, and energy stations. Their stable high-flow output capacity, excellent durability, and reliable independent power system make them irreplaceable in critical infrastructure. In terms of operational economy, the open structure reduces maintenance costs and repair time, facilitates parts replacement, and supports rapid troubleshooting and repair. Due to excellent heat dissipation, unit components operate at lower temperatures, improving stability and lifespan, thereby reducing long-term operating costs. Data provided by the control cabinet can be used for operation and maintenance analysis, using big data monitoring of operating status, maintenance cycles, fuel consumption, and other information to help users develop more scientific operation and maintenance plans and improve overall system efficiency. In summary, open-type diesel fire pump sets, with their core advantages of high reliability, high adaptability, ease of maintenance, and strong power output, ensure a continuous and stable water supply in emergency situations through meticulous design, making them an indispensable piece of equipment in modern fire protection engineering. Its design philosophy balances practicality and safety, and through flexible engineering configurations, stringent manufacturing standards, and excellent operational performance, it meets the high requirements of various buildings and industrial sites for fire water supply systems, providing a solid guarantee for the overall fire safety system. With the continuous development of fire protection technology and the increasing complexity of application scenarios, open-type diesel fire pump sets will continue to play a more crucial role in future projects.