Understand fire pump knowledge and maintenance

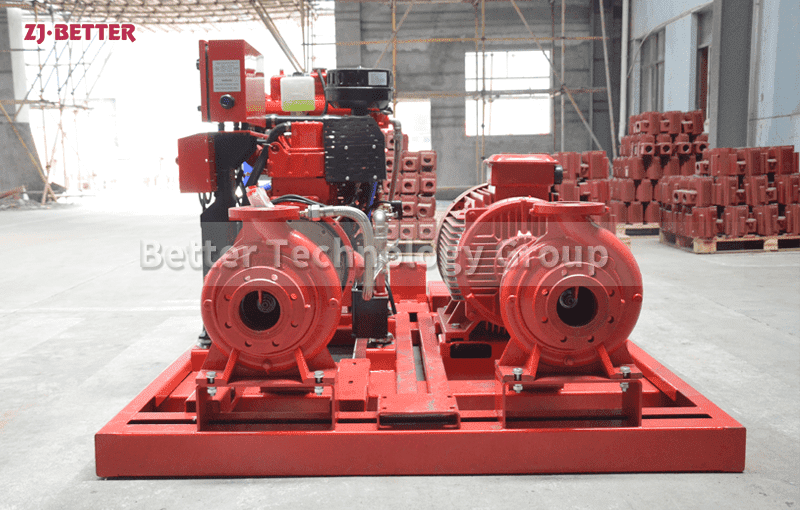

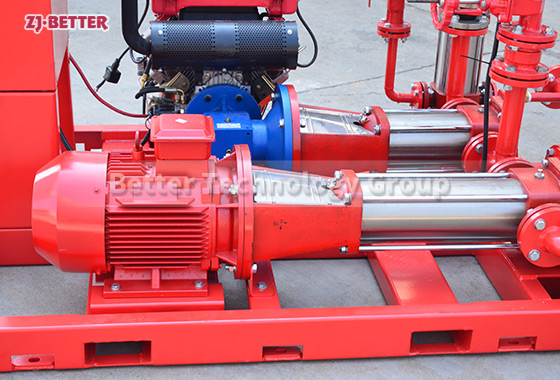

A fire pump is a critical component of a fire sprinkler system, providing the necessary water pressure to ensure the sprinkler system works properly. Fire pumps are usually powered by electric motors or diesel engines and they come in centrifugal, turbine, or rotary types.

To ensure that the fire pump is working properly, it is important to maintain and test it regularly. Regular maintenance tasks include inspecting the motor and fuel system, changing the oil, and checking the battery. Testing the pump pressure and flow rate should also be done on a regular basis. If any issues are found, it is important to contact a professional for assistance. A trained technician should also inspect the fire pump annually.

A fire pump is a critical component of a fire sprinkler system, providing the necessary water pressure to ensure the sprinkler system works properly. Fire pumps are usually powered by electric motors or diesel engines and they come in centrifugal, turbine, or rotary types. To ensure that the fire pump is working properly, it is important to maintain and test it regularly. Regular maintenance tasks include inspecting the motor and fuel system, changing the oil, and checking the battery. Testing the pump pressure and flow rate should also be done on a regular basis. If any issues are found, it is important to contact a professional for assistance. A trained technician should also inspect the fire pump annually.