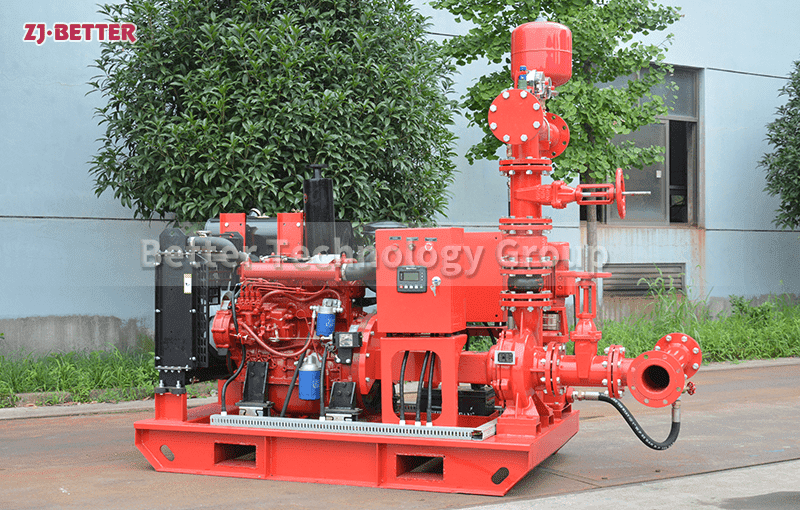

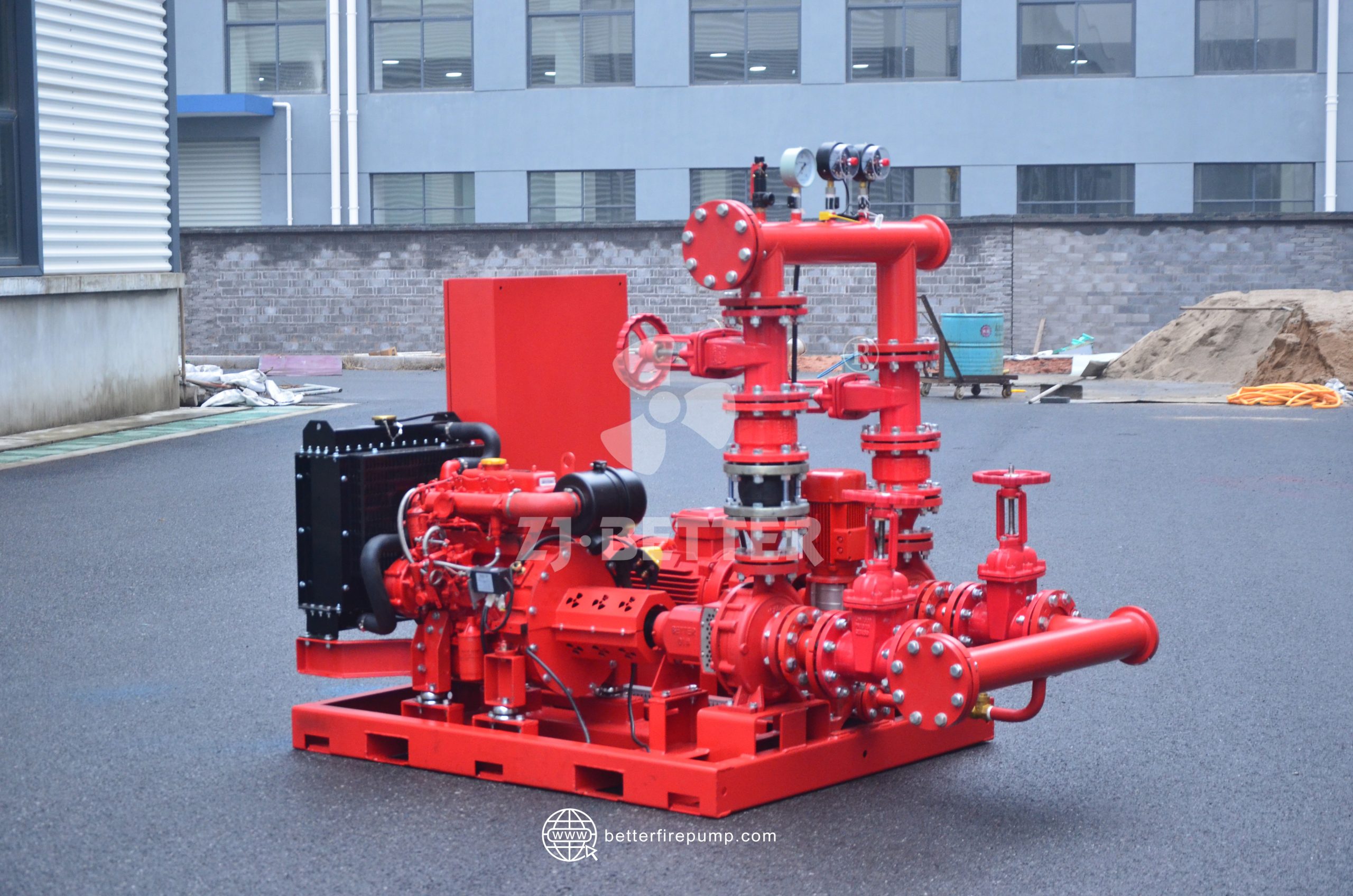

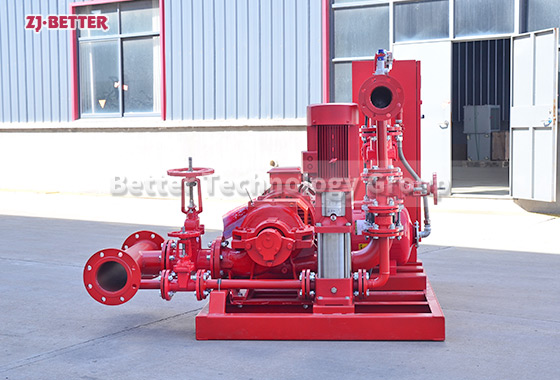

Packaged Vertical Fire Pump Unit for Reliable Building Fire Water Supply

Complete vertical fire pump units are suitable for building fixed fire protection systems. They feature compact structure, rapid start-up, stable pressure output and continuous water supply performance, and integrated control and piping design, providing reliable fire water supply for sprinkler and fire hydrant systems.

Complete vertical fire pump units are core equipment in modern building fire protection systems, ensuring reliable water supply. They are primarily used in fire hydrant and automatic sprinkler systems, playing a crucial role in rapidly establishing pressure and continuously and stably delivering fire-fighting water during a fire. These vertical fire pump units utilize a motor drive system, combined with a vertical structure and integrated design, giving them significant advantages in terms of floor space, operational stability, and system integration. They are particularly suitable for fixed fire protection systems in high-rise buildings, commercial complexes, industrial plants, warehousing and logistics centers, and various public buildings. The vertical structure design allows the pump and motor to be coaxially arranged, resulting in a short transmission path, high efficiency, and effectively reduced energy loss and mechanical vibration. This ensures stable operation during long standby periods and emergency start-ups, enhancing overall reliability from a structural perspective. The pump body is typically made of high-strength cast iron or ductile iron, possessing excellent pressure resistance and impact resistance. It can adapt to high-head, high-flow-rate fire-fighting water supply demands, maintaining stable system pressure even with multiple simultaneous water usage points, meeting the stringent requirements of building fire protection codes for continuous and safe water supply. The hydraulic components are scientifically designed and precision-machined, with smooth impeller flow channels and high hydraulic efficiency. Within the design operating range, they not only output stable flow and pressure but also effectively reduce operating noise and vibration levels, thereby minimizing the impact on the pump room environment and surrounding building structures. The motor, as the core power source, is typically a specialized motor suitable for firefighting conditions, featuring high starting torque, excellent heat dissipation, and a high insulation class. It can quickly start and reach rated speed after a fire signal is triggered, shortening the system response time and providing valuable time for initial fire suppression. It can also withstand high-load operation for short periods, ensuring uninterrupted firefighting water supply. Complete vertical fire pump units typically integrate control cabinets, piping components, valves, and pressure monitoring devices into a highly integrated overall solution, reducing on-site installation and commissioning workload and improving project delivery efficiency. The control system supports multiple control modes, including automatic start, manual start, and remote linkage. It can reliably link with fire alarm systems and pressure switches, and can be put into operation immediately even in unattended conditions, ensuring the fire protection system is always available. The selection of internal components in the control cabinet prioritizes stability and durability, featuring multiple protection functions including overload, phase loss, and short circuit protection. This ensures safe equipment operation while effectively reducing the risk of malfunctions, providing electrical safety guarantees for the long-term reliable operation of the fire protection system. Pressure gauges and operating status indicators reflect the system’s working status in real time, facilitating daily inspections and maintenance by management personnel and helping to promptly identify and address potential problems. The complete vertical fire pump unit also offers significant advantages in installation and maintenance. Its rigid overall base structure and compact equipment layout are suitable for buildings with limited pump room space. The rational piping layout and valve configuration make inspection and maintenance more convenient, and key components are easy to disassemble and assemble, reducing subsequent operation and maintenance costs. Considering the long-term standby operation of fire protection systems, the equipment has undergone systematic optimization in terms of rust prevention, corrosion resistance, and environmental adaptability. The surface coating has excellent corrosion resistance and can adapt to humid, high-temperature, or large temperature fluctuation pump room environments, ensuring reliable start-up performance and stable operation over many years of operation. In practical applications, this type of complete vertical fire pump unit can provide uniform and stable water supply pressure for the sprinkler system, ensuring that the sprinkler heads open normally as designed and form effective coverage. Simultaneously, it supports the simultaneous use of multiple water guns in the fire hydrant system, meeting the needs of firefighters for continuous water intake and high-intensity firefighting operations. Through reasonable system selection and mature complete unit design, the complete vertical fire pump unit ensures the reliability of building fire water supply while also considering operational efficiency, ease of maintenance, and service life. It is currently an ideal fire water supply solution in building fire protection engineering that combines performance, safety, and economy.