Highly Integrated Fire Pump Station: Exceptional Fire Control from Design to Deployment

The integrated diesel and electric dual-power fire pump system delivers reliable and efficient fire protection with intelligent control, auto-switching, and compact design—ideal for high-rise buildings, data centers, and warehouses requiring advanced fire safety solutions.

As modern buildings demand higher standards for fire protection systems, traditional fire pump systems relying on a single power source have begun to reveal issues with operational reliability. Faced with the stringent fire protection challenges posed by high-rise buildings, industrial parks, warehousing facilities, and other critical locations, ZJ-BETTER Company, leveraging its years of experience in fire pump manufacturing, has introduced this ” Integrated Diesel-Electric Dual-Power Fire Pump System.” This system not only integrates dual-power drive systems combining electric motors and diesel engines but also achieves an integrated design for the pump system, significantly enhancing emergency response capabilities and system stability, thereby providing unparalleled fire protection for buildings.

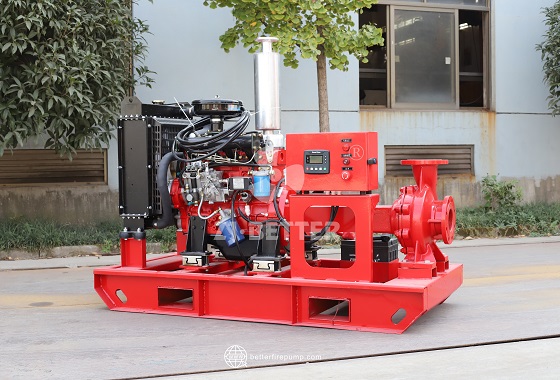

This integrated pump set adopts a base-mounted integrated layout, with the diesel engine, water pump, electric motor, automatic control cabinet, piping system, and alarm system all installed on an integrated base, forming a compact and efficient independent unit. This design not only saves installation space but also greatly simplifies the system installation process and subsequent maintenance work. Additionally, thanks to the standardized modular design philosophy, users can flexibly select the appropriate pump type and power combination based on different flow and head requirements, truly achieving “customization on demand.”

In terms of operational efficiency, the pump set supports an electric-priority, diesel-backup operational logic. Under normal conditions, the electric motor drives the pump system to operate, achieving high-efficiency, low-energy consumption routine water supply. In the event of a power outage or electrical system failure, the diesel engine automatically switches to take over, ensuring uninterrupted water supply. The seamless integration of the dual-power system eliminates the risk of the fire protection system becoming “paralyzed” due to power failure, significantly enhancing the building’s self-rescue capabilities in the event of a sudden fire.

Notably, the ZJ-BETTER integrated dual-power fire pump set is equipped with an intelligent control system, enabling full-process automation. The system features an LCD human-machine interface, supporting manual, automatic, and remote control modes, and offers advanced functions such as fault self-diagnosis, operation record query, and parameter presetting. Through an RS485 communication interface, the equipment can be integrated into an intelligent building management system, enabling comprehensive visualization and intelligent management of the fire protection system, significantly improving operational efficiency.

In terms of materials and structural strength, ZJ-BETTER strictly selects high-quality corrosion-resistant materials such as cast iron, carbon steel, and stainless steel. The pump body surface is treated with fire-resistant red epoxy coating to ensure stable long-term operation in high-temperature, high-humidity, and highly corrosive environments. Each power unit undergoes precise dynamic balancing tests and prolonged operational tests to ensure low vibration, minimal noise, and extended service life. Prior to shipment, the equipment must pass over 20 rigorous factory inspection procedures to ensure that each pump unit meets national fire safety standards and the specific application requirements of the customer’s site.

Additionally, the product supports customizable features such as silent-type units, seismic-resistant bases, explosion-proof electrical control systems, and automatic remote alarm systems—further enhancing its adaptability. Whether in commercial office buildings with strict noise control requirements or mountain tunnels facing seismic risks, ZJ-BETTER provides highly tailored solutions.

In summary, the ZJ-BETTER integrated diesel-electric dual-power fire pump set is a high-end fire protection product that excels in terms of safety, reliability, intelligence, energy efficiency, and adaptability. It is particularly suitable for critical fire protection facilities such as airports, high-rise residential buildings, data centers, underground utility tunnels, and large warehouses. While enhancing users’ fire safety protection capabilities, it also provides an efficient and hassle-free pump set integration solution for engineering projects.