Enhance Fire Safety with Reliable Fire Pressure Stabilization Equipment

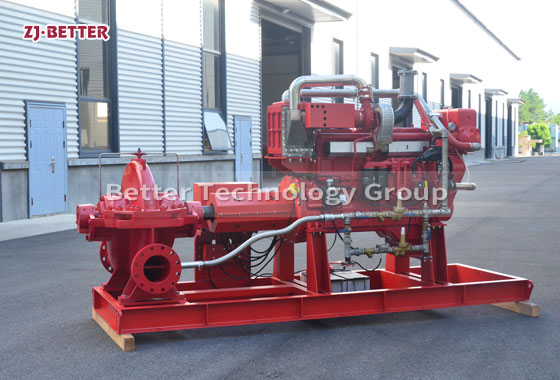

The Fire Pressure Stabilization Equipment, coupled with the CDL Vertical Multistage Fire Pump, offers a comprehensive solution to elevate fire safety measures. This powerful combination ensures a consistent water pressure for effective fire suppression. By incorporating pressure stabilization technology, this system guarantees an uninterrupted fire water supply, efficient water distribution, and reliable operation of fire hydrants and sprinkler systems. With advanced infrastructure and the ability to maximize firefighting capabilities, this configuration significantly enhances overall fire safety standards. Investing in fire pressure stabilization equipment is a proactive step towards ensuring superior fire protection and providing peace of mind in critical situations.

In the field of fire protection, maintaining a reliable and consistent water supply is essential for effective fire suppression. Fire Pressure Stabilization Equipment, consisting of a Stabilization Tank paired with a CDL Vertical Multistage Fire Pump, offers an advanced solution to ensure optimal fire safety measures. This combination provides a dependable water pressure source, enabling efficient and swift response to fire emergencies. Let’s delve into the key features and benefits of this powerful fire pressure stabilization equipment.

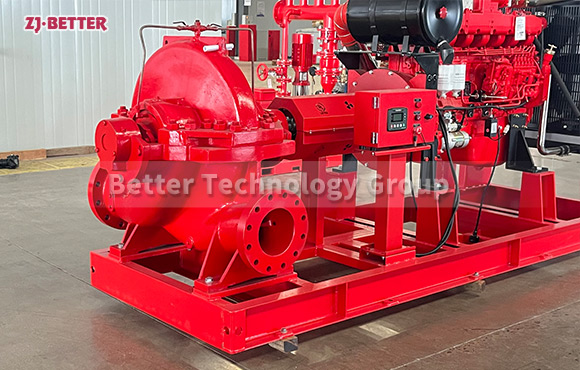

1.Reliable Water Pressure:The Fire Pressure Stabilization Equipment guarantees a consistent water pressure for firefighting systems, eliminating the risk of pressure fluctuations during critical situations. With the Stabilization Tank efficiently regulating water pressure and the CDL Vertical Multistage Fire Pump maintaining the desired pressure level, you can rely on a stable water supply for immediate fire suppression.

2.Efficient Fire Suppression:The CDL Vertical Multistage Fire Pump, integrated into the fire pressure stabilization system, ensures high-performance water delivery. It offers multiple stages of impellers designed to handle increased pressure demands, resulting in efficient water flow and effective fire suppression. This combination optimizes firefighting efforts, minimizing response time and reducing the impact of fire incidents.

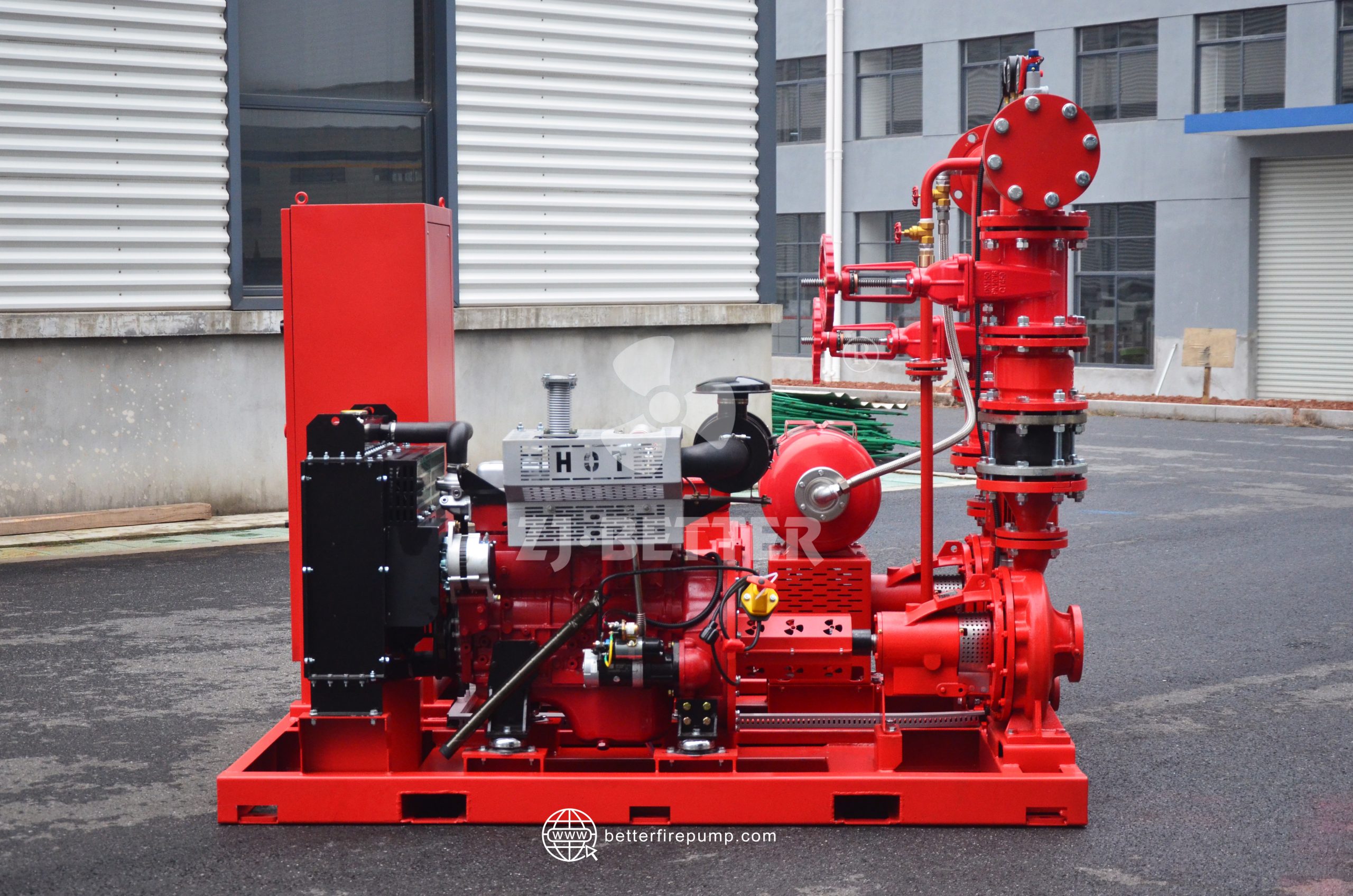

3.Flexible Application:The Fire Pressure Stabilization Equipment is versatile and can be tailored to various fire protection systems. Whether for commercial buildings, industrial facilities, or residential complexes, this equipment configuration adapts to diverse environments and specific water pressure requirements, ensuring comprehensive fire safety coverage.

4.Reliability and Durability:Built with robust materials and engineered with precision, both the Stabilization Tank and CDL Vertical Multistage Fire Pump demonstrate exceptional reliability and durability. These components are designed to withstand demanding firefighting conditions, ensuring long-lasting performance and minimal maintenance requirements.

5.Enhanced Fire Safety Infrastructure:By integrating the Fire Pressure Stabilization Equipment into your fire protection infrastructure, you elevate the overall fire safety standards of your premises. The reliable water pressure and efficient water delivery system enhance the effectiveness of fire sprinklers, hydrants, and other firefighting equipment, providing an added layer of protection against fire incidents.