Efficient Hydraulic Performance: Key Role of Inline Fire Pumps in Fire Protection Systems

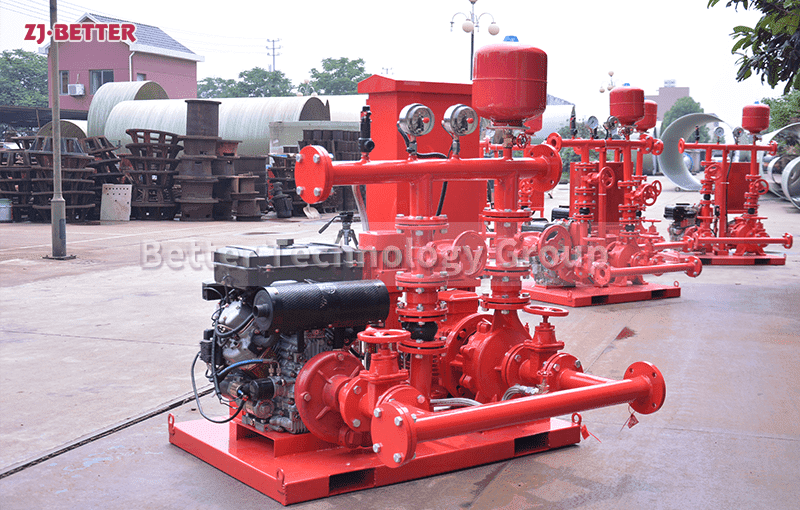

Pipeline fire pumps have become the core equipment of fire protection systems with their high hydraulic performance, stable water supply and energy-saving advantages. They are suitable for high-rise buildings, industrial plants and public facilities, ensuring sufficient water pressure and reliable operation during fire fighting.

In modern building fire protection systems, inline fire pumps, with their unique structure and superior hydraulic performance, have become essential equipment for ensuring fire water supply. These pumps utilize a vertical or inline design, enabling close integration between the pump and the pipeline, significantly reducing installation space requirements and piping complexity. This makes them an ideal choice for fire protection systems in high-rise buildings, commercial complexes, industrial plants, and various large public facilities. Their high hydraulic performance is reflected not only in their robust water supply capacity but also in their ability to maintain a stable and continuous water pressure during critical moments, ensuring a reliable and immediate water supply to sprinkler systems, fire hydrant systems, and other fire terminals. Inline fire pumps typically utilize optimized impeller and pump body structures in their hydraulic design, effectively reducing hydraulic losses and improving energy conversion efficiency. This results in higher flow output and more stable head performance for the same power output. This advantage makes them particularly effective in firefighting applications, as firefighting often requires a long-term, high-flow, and stable pressure water supply, which inline fire pumps perfectly meet. Their high hydraulic performance reduces fluctuations in water supply, thus preventing pressure deficiencies that can compromise firefighting effectiveness. In addition, inline fire pumps exhibit excellent stability and durability during operation. Their use of wear-resistant materials and sealing technology ensures that their performance remains stable even during high-intensity operation. This is particularly important for firefighting equipment that operates in standby mode for extended periods but must be readily available. This reliable durability ensures that firefighting equipment can respond immediately to sudden fires without delays due to malfunctions or performance degradation. Their design also takes installation and maintenance convenience into account. Their vertical, direct-coupled structure not only saves space but also facilitates direct connection to the piping system, reducing the need for additional pipes and infrastructure. The coaxial design of the motor and pump body reduces coupling components, thereby reducing energy loss and the probability of mechanical failure. This makes inline fire pumps significantly advantageous in terms of both installation and long-term operating costs. In terms of performance, inline fire pumps operate efficiently across a wide range of flow rates and head, adapting to buildings of varying sizes and varying firefighting requirements. Their efficient hydraulic performance ensures stable water pressure and flow rate even under complex operating conditions, making them widely used in modern urban firefighting systems. As fire safety standards continue to improve, pipeline fire pumps are incorporating more intelligent elements into their designs. For example, these pumps integrate with automatic control systems, pressure sensors, and remote monitoring equipment to enable fully automatic start-stop, fault alarms, and remote operation and maintenance management. This not only improves system reliability but also reduces manual intervention, allowing fire protection systems to automatically maintain optimal operating conditions without human intervention. High hydraulic performance is the result of scientific fluid dynamics design and rigorous manufacturing processes. Continuous optimization of the impeller curve, pump flow path, and sealing structure allows pipeline fire pumps to improve hydraulic efficiency while effectively reducing noise and vibration. This is particularly important for locations such as office buildings, hospitals, and hotels that require quiet operation. Furthermore, the energy-saving advantages of pipeline fire pumps are also worthy of attention. High hydraulic performance not only ensures a stable and reliable fire water supply but also reduces electricity consumption, significantly reducing energy costs over the long term, in line with the trend of energy conservation and sustainable development in modern buildings. Overall, the key role of pipeline fire pumps in fire protection systems is reflected in the following aspects: First, they provide efficient and stable hydraulic performance, ensuring sufficient water pressure and flow during firefighting; second, their compact design saves space and reduces installation difficulty, making them suitable for a variety of building environments; third, they are stable and durable, ensuring immediate response in emergency situations; fourth, they have the potential for intelligent upgrades, seamlessly integrating with modern fire automation systems; and fifth, they are energy-efficient and cost-effective, meeting the needs of green environmental protection and long-term economic operation. These combined advantages make pipeline fire pumps not just fire water supply equipment, but also the backbone of the stable and efficient operation of the entire fire protection system. Based on their efficient hydraulic performance, they ensure fire safety in buildings at critical moments, providing a solid protection for people’s lives and property. As the scale of buildings continues to expand and fire safety requirements become increasingly stringent, the use of pipeline fire pumps will become more prevalent, and their role in fire protection systems will become even more important. Their efficient hydraulic performance not only represents the current state of the art in fire water supply technology, but also provides direction and momentum for the future development of the fire protection industry.