Continuous Water Supply Assurance: Critical Role of Diesel Fire Pump Sets in Large Industrial Facilities

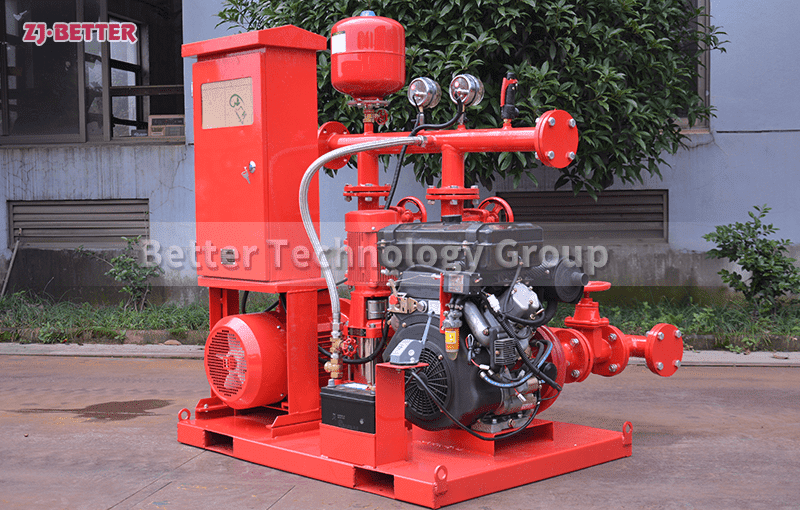

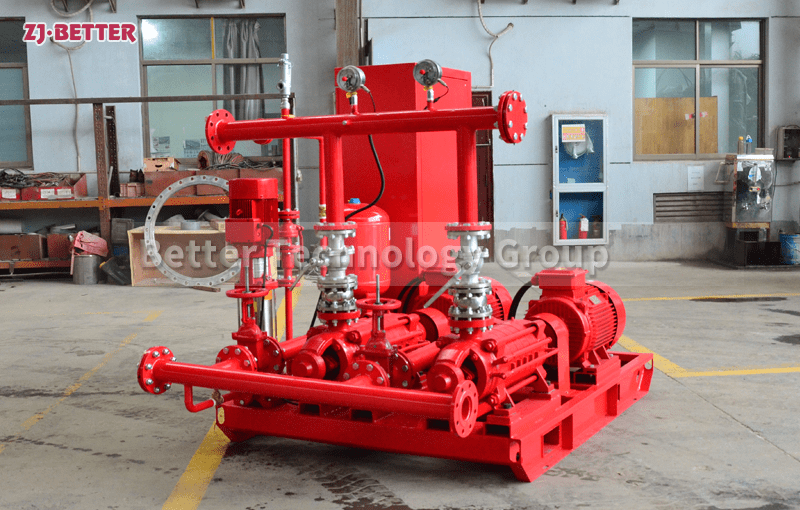

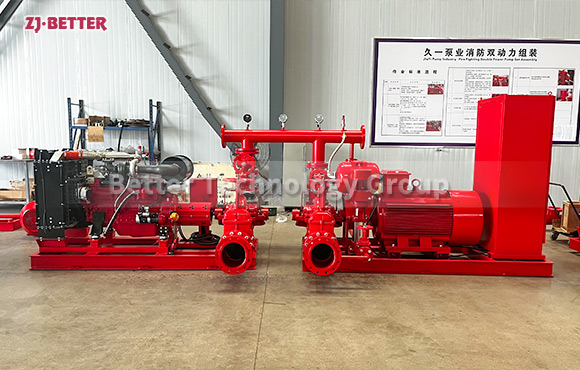

Diesel engine fire pump sets provide independent drive and continuous water supply for large industrial facilities. They have the advantages of fast start-up, high water pressure output, adaptability to harsh environments and intelligent control, ensuring safe and stable operation of fire emergency and production.

Ensuring a continuous water supply plays an irreplaceable role in large-scale industrial facilities. As the core equipment in emergency water supply systems, diesel fire pumps, with their independent power and efficient performance, are the preferred solution for ensuring a stable water supply in critical moments. For large industrial facilities, whether petrochemical plants, steel mills, storage and logistics bases, or power stations and port hubs, fire safety and water supply stability are directly related to the continuity of production operations and the safety of employees and property. In these locations, diesel fire pumps, with their grid independence, can quickly operate in the event of power outages, sudden disasters, or fire emergencies, providing reliable water pressure and a continuous water supply, thus becoming a solid support for emergency response systems. The primary advantage of diesel fire pumps is their independent operation. They do not rely on external power grids, and their high-performance diesel engines enable them to maintain self-starting capabilities even in a complete power outage. This feature is particularly important for large industrial facilities, where power systems are prone to interruptions during fires and other emergencies. Diesel fire pumps can start up and operate within seconds, providing a robust water supply for firefighting systems and effectively preventing damage from escalating due to water supply delays. Secondly, diesel fire pump sets demonstrate exceptional performance in continuous water supply. Their highly efficient engine and pump design enables them to maintain stable water pressure output over extended periods of operation. For fire protection systems in large industrial facilities, sustained, high-flow water supply is crucial for extinguishing large-scale fires. Diesel fire pump sets are optimized to handle these demands while maintaining reliability and durability under high-load conditions. Thirdly, the value of diesel fire pump sets lies in their adaptability and multi-scenario deployment capabilities. Large industrial facilities are often located over vast areas and face complex environments. Some are far from municipal power lines, while others are exposed to high temperatures, dust, or corrosive gases. With their robust structure and high-level protection, diesel fire pump sets operate stably in these harsh environments, ensuring uninterrupted water supply and becoming essential equipment for ensuring production safety. Diesel fire pump sets also offer significant advantages in ease of maintenance and use. Modern diesel fire pump sets are equipped with automatic monitoring and intelligent control systems that monitor key parameters such as engine temperature, water pressure, and oil pressure in real time. They also feature fault alarms and self-protection features, significantly enhancing operational safety and reliability. Furthermore, their compact design and easy maintenance allow for routine inspections and parts replacement to be completed quickly on-site, reducing maintenance costs and extending the overall equipment lifespan. Another significant performance advantage of diesel fire pump sets is their rapid response capability. In large industrial facilities, fires spread extremely quickly, and effective fire control requires equipment that can start and provide water in the shortest possible time. Diesel fire pump sets utilize advanced self-starting devices and highly sensitive control systems to ensure immediate operation upon receiving a signal. Their reliable emergency response capabilities are crucial for responding to sudden fires. Beyond firefighting, diesel fire pump sets can also be used in large industrial facilities for production cooling and backup water supply. For example, in steel refineries, equipment in high-temperature smelting processes requires enormous cooling water. In the event of a municipal water supply interruption, diesel fire pump sets can immediately take over the water supply, ensuring uninterrupted production. In the chemical and energy sectors, diesel fire pump sets can also serve as a backup water source, ensuring stable cooling and protection for process equipment and storage tanks in emergencies. Furthermore, the energy-saving and environmental performance of diesel fire pump sets is continuously improving. Technological advancements have enabled modern diesel engines to adopt low-emission designs, resulting in higher combustion efficiency and improved noise control. This allows equipment to maintain stable performance in demanding environments while also meeting the stringent environmental requirements of modern industry. Regarding energy conservation and cost reduction, diesel fire pump sets achieve a balance between cost-effectiveness and reliability by optimizing fuel consumption and improving mechanical efficiency, thereby reducing operating costs for large-scale industrial facilities. The widespread global application of diesel fire pump sets demonstrates their value and irreplaceable role in large-scale industrial facilities. As a core component of emergency water supply systems, they are not only a vital component of fire safety systems but also crucial for maintaining production continuity and protecting personnel. In the face of various threats such as fire, natural disasters, or sudden power outages, diesel fire pump sets can consistently and reliably provide a continuous water supply, minimizing risks and losses. In summary, diesel fire pump sets, with their independent operation capabilities, continuous water supply, adaptability to harsh environments, rapid response, intelligent control, and environmental and energy-saving advantages, have become indispensable equipment for ensuring fire safety and stable production in large-scale industrial facilities. It is not only a fire pump, but also a strategic guarantee in the emergency water supply system of the entire industrial facility. Its value far exceeds the equipment itself and is the key to safety, efficiency and sustainable development.