Integrated Stainless Steel Fire Water Tank System for Efficient Emergency Supply

Discover the benefits of an integrated stainless steel fire water tank system designed for efficient emergency water supply. Featuring corrosion-resistant materials, automatic controls, and high-performance fire pumps, this plug-and-play solution is ideal for commercial, industrial, and residential fire protection applications worldwide.

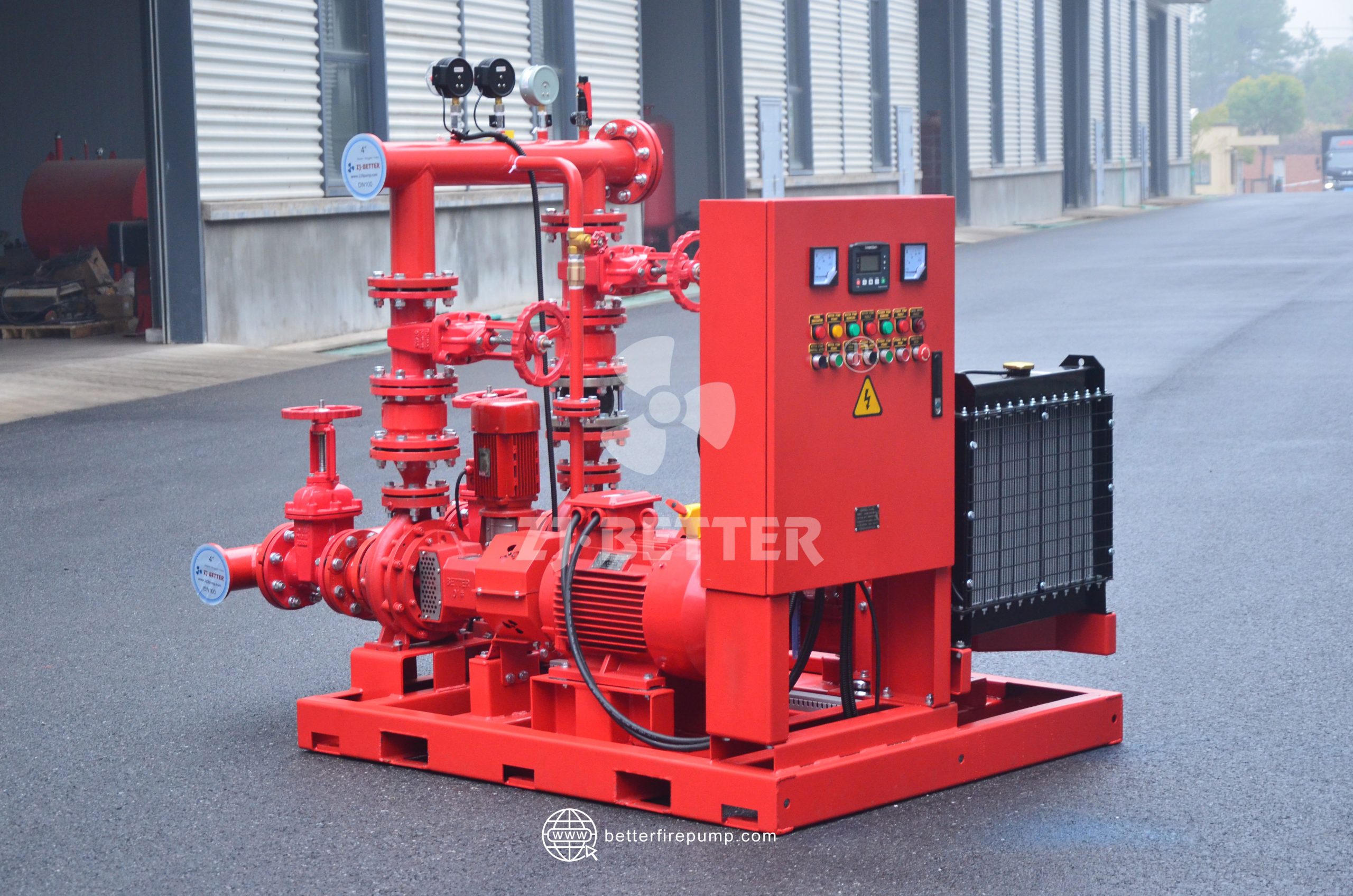

The integrated stainless steel fire water tank system for efficient emergency supply is a modern, space-saving, and high-performance firefighting solution that combines the essential components of water storage and pump activation in a compact and modular design. Designed for fire protection systems in both commercial and industrial environments, this setup includes a robust stainless steel water tank, advanced fire pump mechanisms, automatic control panels, and strategically aligned pipework, all pre-installed on a single steel base for seamless transportation and rapid deployment. The stainless steel tank is made of high-grade SUS304 or SUS316 material, known for its excellent corrosion resistance, long lifespan, and hygienic water storage capability, making it suitable for clean and reliable firewater retention even in environments with high humidity or aggressive chemicals. One of the main advantages of this system is its plug-and-play installation: unlike traditional on-site assembly which requires civil engineering, piping, electrical work, and extended project timelines, this integrated unit can be transported to the designated site and quickly connected to the external piping and power systems, significantly reducing construction costs and time-to-use. The integrated fire pump is designed for high-pressure output and continuous duty cycles, ensuring dependable water flow during critical moments when firefighting water is required instantly. Powered by a reliable electric motor or diesel engine—depending on project specification—the pump is capable of delivering high flow rates ranging from 20 to over 200 liters per second, with working pressures between 0.4 to 1.6 MPa, which can cover the hydraulic demands of high-rise buildings, industrial warehouses, hospitals, schools, residential areas, and logistic centers. The automatic control cabinet enables unmanned operation and real-time status monitoring, equipped with features such as dry-run protection, automatic switching between power sources, alarm systems, and failure diagnostics. It is compatible with remote monitoring systems and smart building management platforms, supporting Modbus RTU or TCP/IP protocols for real-time connectivity. An intelligent pressure sensor and flow meter are also integrated to ensure accurate operation under variable demand conditions. The stainless steel tank is customizable in capacity, ranging from 1 to 100 tons, and features modular square panel construction which allows it to be installed in irregular spaces or expanded as demand increases. The internal structure is reinforced with stiffeners to prevent bulging under hydraulic pressure, and all welding is done by argon arc techniques to ensure leak-proof durability. The system includes anti-vortex inlets, sediment control, manholes for maintenance access, and ladder installations for tank inspection. Optional thermal insulation and heating modules can be added for use in extremely cold climates, ensuring year-round readiness. Beyond the robust mechanical performance, the aesthetics and practical design of this fire water tank system also enhance its value. Its compact footprint allows for rooftop, basement, or outdoor installations without occupying valuable building interior space. Its red-painted frame and polished stainless tank panels also contribute to a modern and professional look, aligned with international safety equipment standards. Furthermore, the system complies with major global certifications such as UL, FM, NFPA, CE, ISO9001, and CCCF, ensuring that it meets the rigorous requirements for firefighting systems in international projects. Users benefit from reduced maintenance overheads due to the corrosion-resistant nature of stainless steel and the self-cleaning capabilities of the system’s internal flow dynamics. The pump and motor assembly are mounted on vibration-dampening bases, minimizing noise and mechanical wear during operation. Seals and couplings are made of high-quality materials such as Viton, PTFE, or carbon ceramics to resist high temperatures and chemical exposure. In addition, energy efficiency is a key focus of the design. The electric control system is capable of frequency conversion operation, which adjusts motor speed in response to changing water pressure needs, optimizing energy usage while prolonging motor and pump life. This is especially important for systems that need to remain in standby mode for long durations but must respond instantly during emergencies. For diesel-powered variants, the engine features fast ignition capability, low fuel consumption, and self-diagnostic technology that alerts the user in case of low oil pressure, overheating, or fuel blockages. Installation of this fire tank system does not require specialized skills or labor; it is shipped fully assembled with all necessary testing completed at the factory, including hydraulic pressure tests, electrical insulation tests, and pump performance curves verification. This ensures end users receive a product that is both reliable and easy to implement. Moreover, the modular layout enables easy upgrades, component replacements, or expansion without dismantling the entire unit. All spare parts are standardized for global availability, and optional accessories such as flow switches, air release valves, anti-return valves, and bypass systems can be included depending on the project specification. Industries that benefit most from this system include textile mills, petrochemical plants, food processing facilities, airports, shopping malls, and utility infrastructures, where consistent water availability and quick system activation can mean the difference between safety and disaster. The system is also ideal for developing countries or regions with limited fire infrastructure, as it can be placed as a standalone unit near vulnerable buildings to provide immediate protection until municipal firefighting resources arrive. In summary, the integrated stainless steel fire water tank system is a forward-thinking solution that merges structural integrity, hydraulic reliability, electrical automation, and environmental compatibility into one cohesive platform. Its application simplifies the firefighting design process, reduces implementation risk, and elevates the overall safety standards of the facilities it protects. By adopting this integrated approach, facility managers, construction contractors, and developers can ensure their buildings are safeguarded by a system that is not only technologically advanced but also practical, durable, and ready to operate at a moment’s notice.