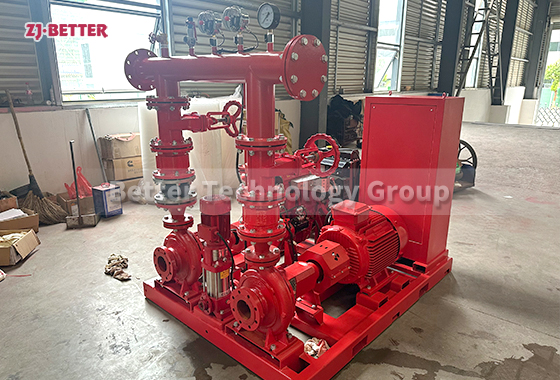

Engineering-Grade Diesel Fire Pump Set with High Head, High Flow, and Superior Durability

Heavy-duty diesel fire pump unit delivering strong power, high pressure and reliable water supply for industrial, commercial and high-risk facilities, ensuring stable fire protection in any emergency.

Heavy-duty diesel fire pump units, as crucial core equipment in modern fire protection systems, play an irreplaceable role in fire water supply systems for industrial facilities, commercial buildings, energy bases, municipal engineering projects, and high-risk areas. These units are renowned for their high head, high flow rate, high durability, and powerful output. Driven by independent diesel engines, they are not limited by power supply and can maintain continuous and stable operation even in the event of power outages, line faults, or emergencies, ensuring a reliable water supply for fire response measures. To meet the stringent requirements of large-scale engineering projects, the petrochemical industry, warehousing and logistics parks, and high-rise buildings for fire water volume and pressure, heavy-duty diesel fire pump units typically employ reinforced base structures, optimized hydraulic channel designs, superior cooling systems, automatic control systems, and high-temperature and corrosion-resistant materials, enabling them to maintain efficient and stable water supply performance in various complex environments. Firstly, the power core of the heavy-duty diesel fire pump unit—the diesel engine—is highly tuned to maintain stable torque output during prolonged full-load operation. Unlike electric fire pumps that rely on mains power, diesel fire pumps have independent drive capabilities, making them suitable for remote areas without electricity, areas with frequent power outages, or industrial sites with unstable power systems. Diesel engines are characterized by low fuel consumption, high efficiency, rapid response, and high starting reliability. They can quickly reach operating speed after receiving a start command, ensuring that the fire protection system can achieve the goals of “rapid water supply, powerful water supply, and continuous water supply” in emergencies. Furthermore, heavy-duty units are typically equipped with a dual-battery starting system and preheating function, ensuring successful engine ignition even in low-temperature environments, thus significantly improving the reliability of the equipment. Secondly, the pump body structure is designed for heavy-duty operation to meet the requirements of high flow and high pressure. Fire pumps are generally made of high-strength cast iron or ductile iron, possessing excellent mechanical strength, wear resistance, and corrosion resistance, thus ensuring that hydraulic efficiency does not decrease during long-term operation and reducing flow attenuation due to wear. The pump body’s hydraulic model is optimized into a high-efficiency curve. Computational fluid dynamics technology reduces internal flow resistance, increasing head and efficiency, ensuring stable pressure output even during long-distance water transport or high-rise building water supply. The impeller, made of wear-resistant material and rigorously balanced, effectively reduces vibration, improves operational stability, and extends the overall service life of the unit. Furthermore, the control system plays a crucial role in heavy-duty diesel fire pump units, featuring intelligent functions such as automatic start-up, pressure monitoring, fault alarms, oil level detection, water temperature monitoring, and engine operating status display. When the fire pipeline pressure drops below a set range, the control system automatically issues a start command, rapidly bringing the diesel engine into operation. The integrated intelligent protection system automatically alarms and shuts down the pump in cases of low oil pressure, high water temperature, abnormal speed, or excessive load, preventing machine damage. Modern heavy-duty diesel fire pumps can also be equipped with a remote monitoring system for real-time transmission of pump operation data, facilitating remote maintenance and status management by fire control centers or project managers. The heavy-duty base is crucial for the overall stability of the unit. The base is constructed from thickened steel plates and its structural layout is optimized through gravity calculations, minimizing resonance during high-speed operation and preventing bolt loosening, pipe leaks, or bearing damage caused by vibration. The base boasts extremely high load-bearing capacity, remaining stable even when a large pump body and a high-power diesel engine are operating simultaneously, allowing the entire system to operate continuously in harsh environments. Furthermore, the base is typically equipped with lifting points and transport holes, improving installation convenience on-site and reducing construction time and labor costs. The cooling system is also an indispensable component of heavy-duty diesel fire pump units. The unit employs an air-cooled or water-cooled system, equipped with a radiator, coolant circulation system, and forced-air cooling fan, ensuring the engine maintains normal operating temperature even under high-temperature, long-term operation. Some models utilize a closed-loop cooling system to prevent external impurities from entering the cooling circulation, improving system stability and enabling reliable operation in high-dust environments or harsh outdoor weather conditions. Pump unit connecting components such as couplings, mechanical seals, and bearings are reinforced and manufactured with high-precision machining and high-temperature and corrosion-resistant materials to ensure high power transmission efficiency, reliable sealing performance, reduced leakage risk, and improved overall durability. The couplings utilize an elastomer structure to effectively absorb vibration and misalignment, resulting in smoother transmission and reduced failure rates. The mechanical seal structure features high pressure resistance and high wear resistance, capable of withstanding high-speed rotation and high-temperature conditions for extended periods, reducing maintenance frequency and improving the unit’s economic efficiency. Heavy-duty diesel fire pump units demonstrate particularly outstanding practicality in various scenarios. In the petrochemical industry, they can handle high-temperature, corrosive media, and high-risk fire environments, ensuring fire water supply to large oil tank areas or chemical plant areas. In warehousing and logistics parks or large warehouses, they can provide powerful water supply to large areas, effectively addressing the risk of fire spread. In high-rise buildings, their high lift capacity enables stable fire water supply to each floor, ensuring the safety of high-rise residents. In critical infrastructure projects such as mining, airports, ports, and power plants, heavy-duty diesel fire pumps have become core components of emergency and fire protection systems due to their strong self-operating capabilities and durability. In terms of performance stability, heavy-duty diesel fire pump units are characterized by long-term continuous operation without performance degradation, maintaining stable hydraulic output under high loads. Their high-efficiency hydraulic design combined with excellent fuel economy ensures both a strong water supply and reduced long-term operating costs in actual fire protection needs. Durable construction and intelligent control systems further enhance reliability, enabling the unit to intervene in fire protection operations at its optimal state in critical moments. Overall, heavy-duty diesel fire pump units are renowned for their high power, high efficiency, high durability, intelligent control, and high environmental adaptability, making them core equipment in industrial and commercial building fire protection systems. Their independent power drive ensures stable water supply under all conditions, making them an essential choice for areas with significant hazards, critical engineering projects, and high-demand fire protection systems. Considering their structural advantages, technical features, and application value, these units not only improve the overall safety level of the fire protection system, but also provide long-term and reliable protection for the safe operation of engineering projects. They are an indispensable and important piece of equipment in the modern fire protection system.