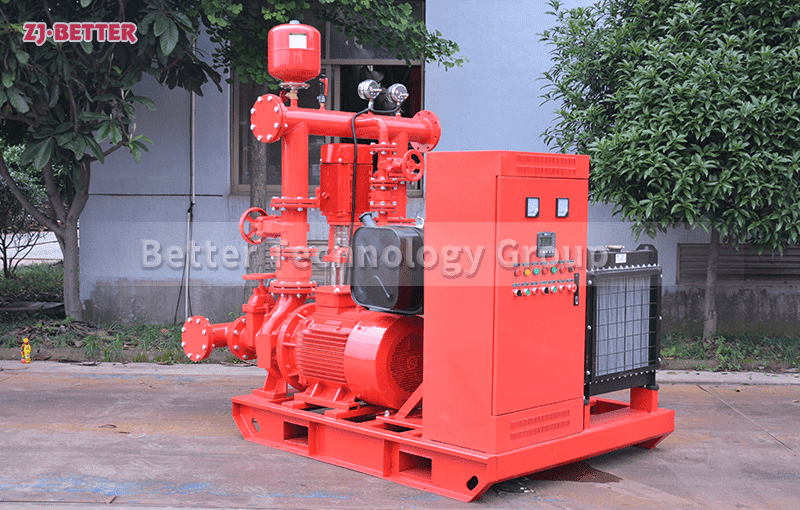

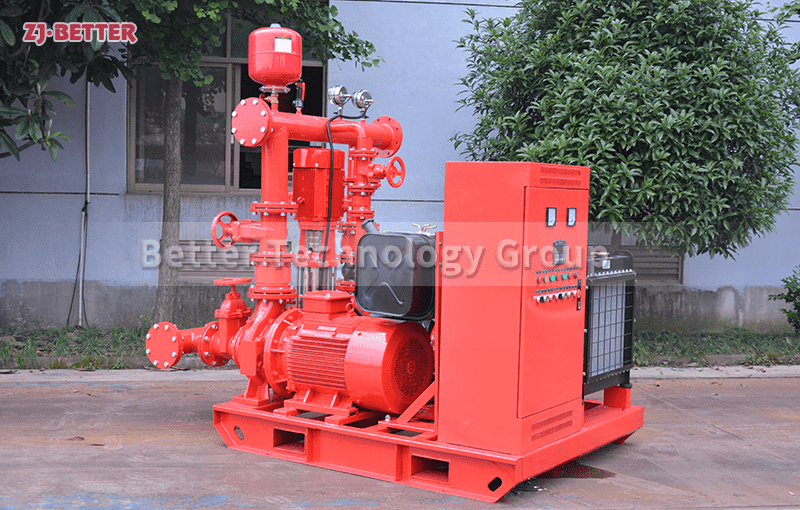

Main Diesel Fire Pump Unit for Fixed Fire Protection Systems

The main diesel fire pump unit is suitable for fixed fire protection systems. It has independent diesel power, rapid start-up capability and stable high flow and high head water supply performance. It can continue to operate in the event of a power outage. The pump body has a robust structure and the control system is intelligent and reliable, meeting the high standards of safety and reliability required by building, industrial and municipal fire protection.

As the core water supply equipment in a fixed fire protection system, the main diesel fire pump unit is the most critical, reliable, and decisive component of the entire fire water supply system. Its primary function is to provide a continuous, stable, high-pressure, and high-flow-rate fire-fighting water supply to the fire pipeline network immediately upon the occurrence of a fire, ensuring that sprinkler systems, fire hydrant systems, and other fixed fire-fighting facilities can be quickly put into operation. Structurally, this type of fire pump unit typically uses a diesel engine as an independent power source, coupled with a high-performance centrifugal fire pump, with power transmitted through a flexible coupling or direct connection. The entire unit is installed on a high-strength steel structure base, forming a complete fire protection system integrating the power system, pump body system, control system, cooling system, fuel system, and safety protection system. This structural design allows the main diesel fire pump unit to maintain a high degree of independence and reliability even in the event of a mains power outage, unstable external power supply, or extreme emergency situations, fully meeting the stringent requirements of fixed fire protection systems for “ready to start and continuously operate.” In terms of performance advantages, the most prominent feature of the main diesel fire pump unit is its strong starting reliability and continuous water supply capacity. Diesel power does not rely on the external power grid; even if the power system is damaged in the early stages of a fire, it can still be quickly started via battery or manual operation, ensuring the fire protection system does not fail due to power outages. Simultaneously, the diesel engine has the ability to operate at full load for extended periods, providing stable power output under high temperature and high load conditions, ensuring a constant speed for the fire pump and guaranteeing the stability of outlet pressure and flow, preventing insufficient pipeline pressure or water volume reduction due to power fluctuations. Regarding pump body performance, main diesel fire pumps typically employ a high-efficiency hydraulic model design. The pump casing is mostly made of high-strength cast iron or ductile iron, possessing excellent pressure resistance and impact resistance. The impeller undergoes precise dynamic balancing and surface anti-corrosion treatment, maintaining low vibration, low noise, and high efficiency output even under high-speed operation, ensuring no abnormal wear or performance degradation during long-term operation under high flow and high head conditions. To meet the stable pressure requirements of fixed fire protection systems, these units are designed with full consideration of changes in pipeline resistance and the actual operating conditions of multi-point water use. By rationally matching pump parameters, they can cover the system’s design flow range at rated speed, avoiding frequent overload operation, fundamentally extending equipment lifespan and reducing later maintenance costs. The control system is also a significant advantage of main diesel fire pump units. Modern fire pump units are generally equipped with intelligent control cabinets, enabling automatic start-up, automatic monitoring, and fault alarms. When the fire pipeline pressure drops or a fire signal is received, the control system can automatically issue a start command, allowing the diesel engine to start and drive the fire pump in a very short time. Simultaneously, it monitors key operating parameters such as oil pressure, water temperature, speed, and battery voltage in real time. In case of any abnormality, it immediately issues audible and visual alarms, helping managers to promptly grasp the equipment status, thereby ensuring that the fixed fire protection system remains under control and safe throughout the entire fire emergency process. In terms of safety performance, primary diesel fire pump units are typically equipped with multiple protection measures, such as overspeed protection, low oil pressure protection, high water temperature alarm, and emergency shutdown function. These designs ensure equipment safety without affecting its continuous operation under fire conditions, guaranteeing that it is “usable, easy to use, and durable” in critical moments. From an adaptability perspective, this type of unit is suitable for various fixed fire protection systems, including high-rise buildings, commercial complexes, industrial plants, warehousing and logistics centers, petrochemical facilities, power systems, and municipal infrastructure. Whether it requires high lift to overcome building height or large flow to meet the water demand of large-area sprinklers and fire hydrants, primary diesel fire pump units can achieve precise matching through appropriate selection. In addition, its modular design facilitates on-site installation and system integration, with a high degree of interface standardization, allowing seamless connection with existing fire pipeline networks, valve systems, and control systems, shortening the construction cycle and reducing installation errors. In terms of maintenance and operating costs, the main diesel fire pump unit has a clear structure and concentrated maintenance points. Routine inspections mainly focus on the fuel system, cooling system, and lubrication system. The maintenance process is standardized and simple to operate. Even when idle for extended periods, it can maintain good operating conditions through regular trial runs, avoiding starting difficulties or performance degradation caused by long-term inactivity. Overall, the main diesel fire pump unit, with its independent power advantage, excellent water supply performance, stable operational reliability, and comprehensive safety and control system, has become an irreplaceable core water supply device in stationary fire protection systems. It not only bears the heavy responsibility of protecting lives and property during fires but also demonstrates high reliability, low failure rate, and long service life in daily operation, serving as a crucial foundation for achieving high-level protection standards in modern stationary fire protection systems.