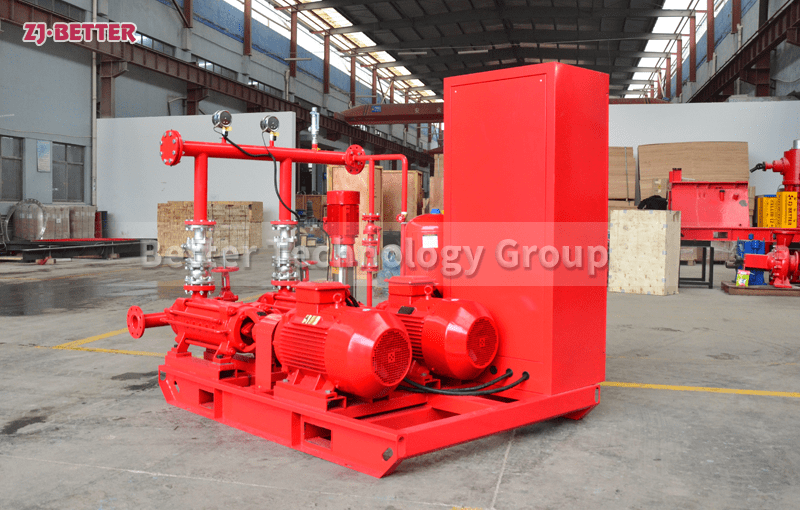

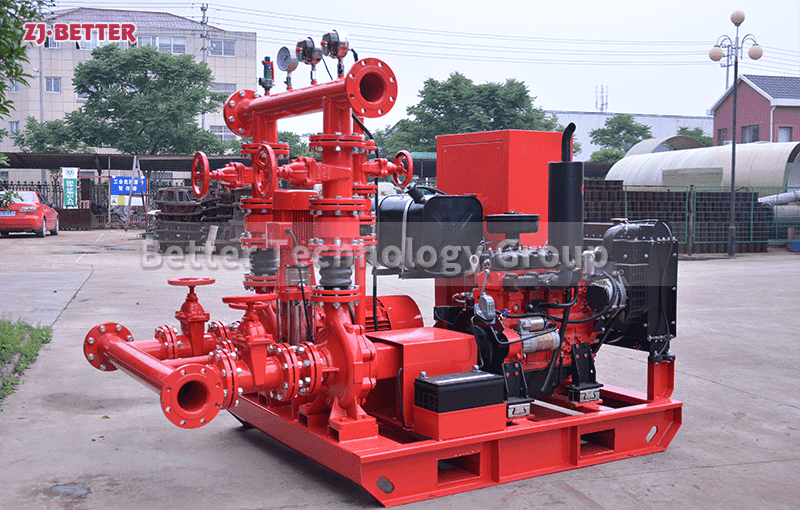

Fire pump equipment is widely used

The use of fire pumps is generally based on different situations. Different types will have different classification methods. The fire pump is in its own fully sealed state, without the possibility of leakage, and can resist corrosion. , is widely used, and is mainly used in fire protection, sewage treatment and some departments of environmental protection. It is used to pump different liquids, so that there is no leakage and no pollution. It is very civilized A kind of fire engine, which is very beneficial to the use of all of us.

Fire pumps for firefighting are mainly used to deliver water to pipelines, or to drain water in cities and industries, and to deliver water to high-rise buildings. This is similar to the need to deliver water due to some cold and hot cycles in long-distance situations. What kind of equipment is used.

Therefore, the role of the fire pump is still very large, and it is widely used. Now everyone can see that the functions are naturally different because of the different places where they are used. This is also a very useful thing depending on the situation. In a specific situation, a specific fire pump is used.