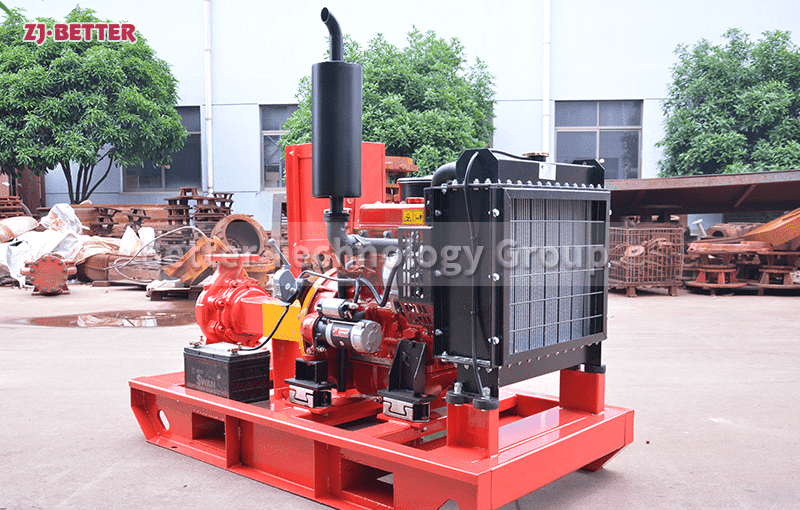

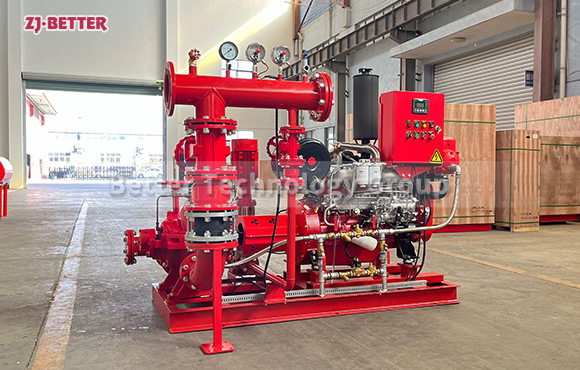

Diesel Driven Fire Pump Set for Emergency Water Supply Without Power Source

Diesel engine-driven fire pump units are suitable for environments with no power supply or unstable power. They have advantages such as independent start-up, stable water output, automatic control, and strong continuous operation capability. They are widely used in fire emergency water supply systems for industrial plants, warehousing and logistics facilities, and important facilities, meeting stringent fire protection requirements.

Diesel engine-driven fire pump units are suitable for emergency water supply systems in environments without power. As an indispensable piece of equipment in modern fire protection engineering, their core value lies in their ability to quickly, reliably, and continuously provide fire-fighting water that meets fire safety standards even under conditions of power outages, unstable power supply, or complete power failure. They are a key component of fire protection systems in industrial plants, petrochemical facilities, warehousing and logistics parks, mines, power plants, tunnels, ports, remote buildings, and various critical infrastructure projects. These fire pump units use a diesel engine as an independent power source, independent of external power systems. They drive the fire pump through mechanical direct coupling or high-efficiency flexible couplings, ensuring immediate operation upon the onset of a fire and preventing fire system failure due to power outages, thus fundamentally improving overall fire safety. The entire unit is designed with stability and reliability in emergency situations in mind. The diesel engine uses a mature and reliable industrial-grade power platform, featuring strong starting performance, ample torque reserve, and high durability. It can operate stably in complex environments such as high temperature, low temperature, humidity, and dust, meeting the stringent requirements for long-term continuous operation of fire pumps. The fire pump section typically employs a single-stage or multi-stage centrifugal pump structure. Its hydraulic model is optimized for high efficiency, stable flow rate, and a smooth head curve, maintaining excellent water output performance under rated and off-peak conditions. This ensures sufficient pressure at the end of the fire hydrant network, meeting the water demands of indoor and outdoor fire hydrant systems, as well as automatic sprinkler systems. The unit generally adopts a skid-mounted structure, integrating the diesel engine, fire pump, cooling system, fuel system, exhaust system, control system, and related pipelines and valves onto a single steel base. This compact structure saves space, facilitates installation, and significantly reduces on-site construction difficulty and time, making it particularly suitable for rapid deployment in emergency or renovation projects. In terms of performance, this diesel engine-driven fire pump unit boasts excellent automation. Its intelligent control system enables automatic start-up, automatic shutdown, real-time monitoring of operating parameters, and fault alarms. When the fire hydrant network pressure drops or a fire alarm signal is received, the unit can start up and rapidly establish rated pressure and flow in a very short time, buying valuable time for firefighting. The control system typically features multiple start-up methods, including automatic start, remote start, and manual emergency start. Even in the event of a control system malfunction, equipment availability can be maintained through mechanical or manual means, fully embodying the design philosophy of “reliability as the first principle” in fire-fighting equipment. The fuel system has a reasonable capacity configuration, supporting continuous operation of the fire pump for a specified period. It also employs multi-stage filtration and safety protection designs to ensure fuel cleanliness and supply stability, preventing engine stalling or power reduction due to fuel issues. The cooling system can be configured with air or water cooling depending on the application environment, effectively controlling engine operating temperature even under high load conditions, ensuring no performance degradation during long-term continuous operation. The exhaust system undergoes silencing and protection treatment, meeting fire-fighting requirements while reducing the impact of noise and high-temperature exhaust on the surrounding environment and personnel, improving overall safety. This type of diesel fire pump unit also demonstrates professional standards in structural strength and material selection. The pump body and key pressure-bearing components are made of high-strength cast iron or alloy materials, possessing excellent pressure resistance and corrosion resistance, enabling long-term operation under different water quality conditions and extending equipment lifespan. The shaft seal typically employs a more reliable mechanical seal structure, effectively reducing the risk of leakage during operation and lowering maintenance frequency. Bearings and rotating components undergo precision machining and rigorous assembly to ensure stable operation and low vibration even at high speeds, reducing mechanical wear and improving overall efficiency. For environments without power supply, the independence of diesel engine-driven fire pump units is particularly advantageous. They eliminate the need for large-capacity generators or complex backup power systems, enabling the construction of a complete and reliable fire water supply system. This not only reduces system construction costs but also minimizes potential failure points, resulting in a simpler and more reliable fire protection system structure. From a maintenance perspective, daily maintenance of this type of unit is relatively clear and straightforward. Regularly checking the fuel, engine oil, coolant, and battery status ensures the equipment is always ready for operation. The control system has self-checking and recording functions, allowing managers to promptly grasp the equipment’s operating status, meeting the requirements of modern fire management for visualization and traceability. In summary, diesel engine-driven fire pump units have become the preferred solution for fire protection projects without power supply or with high safety levels due to their multiple advantages, such as not relying on electricity, rapid start-up, stable operation, strong adaptability, flexible installation, and convenient maintenance. They play an irreplaceable and important role in protecting the lives and property of personnel.