Innovative Fire Pump System Design for Enhanced Safety in Industrial Parks and High-Rise Buildings

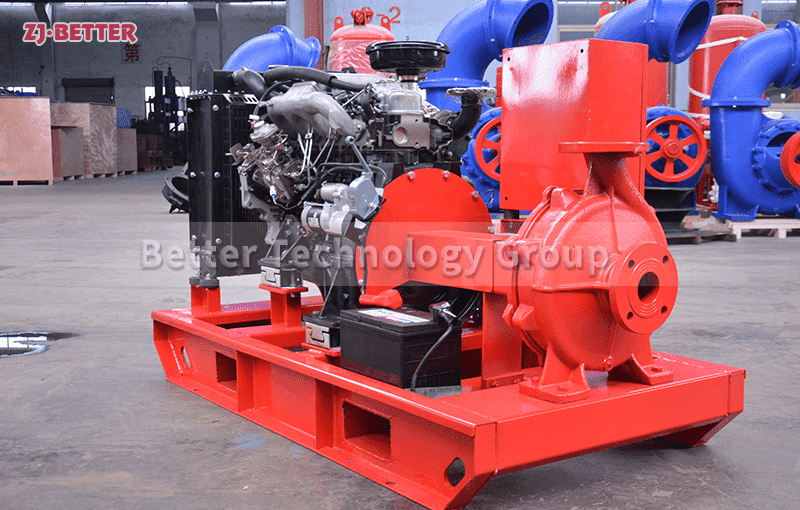

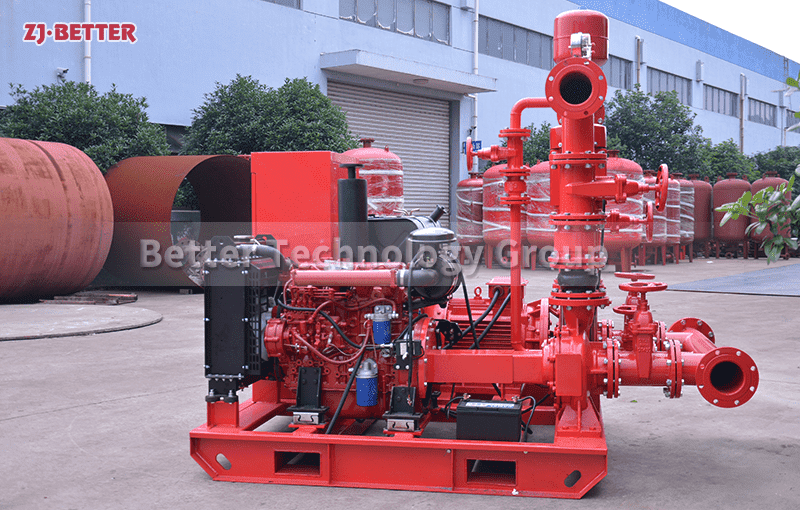

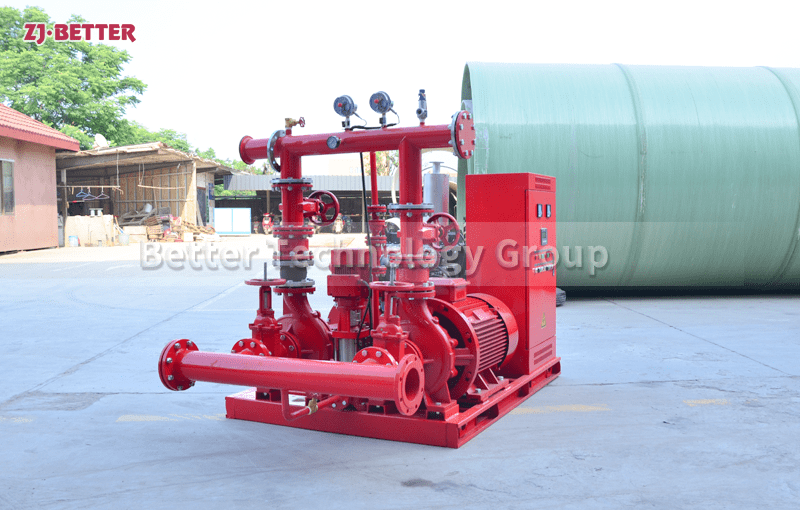

This innovatively designed fire pump system is specifically tailored for environments with high firefighting water supply requirements, such as industrial parks and high-rise buildings. By incorporating high-efficiency pumps and intelligent control technology, the system ensures the rapid provision of high-volume water during a fire, meeting the demands of complex environments. The system integrates both diesel and electric drive motors, combined with an intelligent control panel that offers automatic start-up, water pressure regulation, remote monitoring, and fault alarms, ensuring stability and efficiency during critical moments.

The innovation in this product is also reflected in its modular design, allowing for flexible configuration based on different application scenarios. The system is easy to install and commission, making it adaptable to various complex operational environments. Additionally, its high durability and low maintenance costs ensure that it continues to perform excellently over time, making it the ideal choice for ensuring fire safety in industrial parks and high-rise buildings.

This company specializes in the research, development, manufacturing, and service of fire pump systems, committed to providing efficient and reliable firefighting water pump solutions globally. The product range includes electric fire pumps, diesel engine fire pumps, pressure systems, intelligent control panels, and more, serving a wide array of industries such as high-rise buildings, industrial facilities, public transportation hubs, and municipal projects. By integrating advanced technologies and adhering to stringent quality control standards, we ensure that every unit delivers exceptional performance and reliability.

With a modular design concept and intelligent management systems, our fire pump units offer efficient water pressure supply to meet the demanding firefighting needs in complex environments, enabling rapid response during critical moments. We also offer customized services, designing tailored fire protection systems based on specific requirements to help clients optimize their fire safety systems and improve emergency response capabilities.

With a strong global presence, our products have earned the trust and recognition of customers in numerous countries and regions. Moving forward, we will continue to uphold our core values of “Safety, Innovation, and Reliability” to drive technological advancements in the fire protection industry, providing smarter and more efficient fire protection equipment and services to clients worldwide.