The Power Core for Firefighting: Technological Innovation and Practical Application of Portable Diesel Fire Pumps

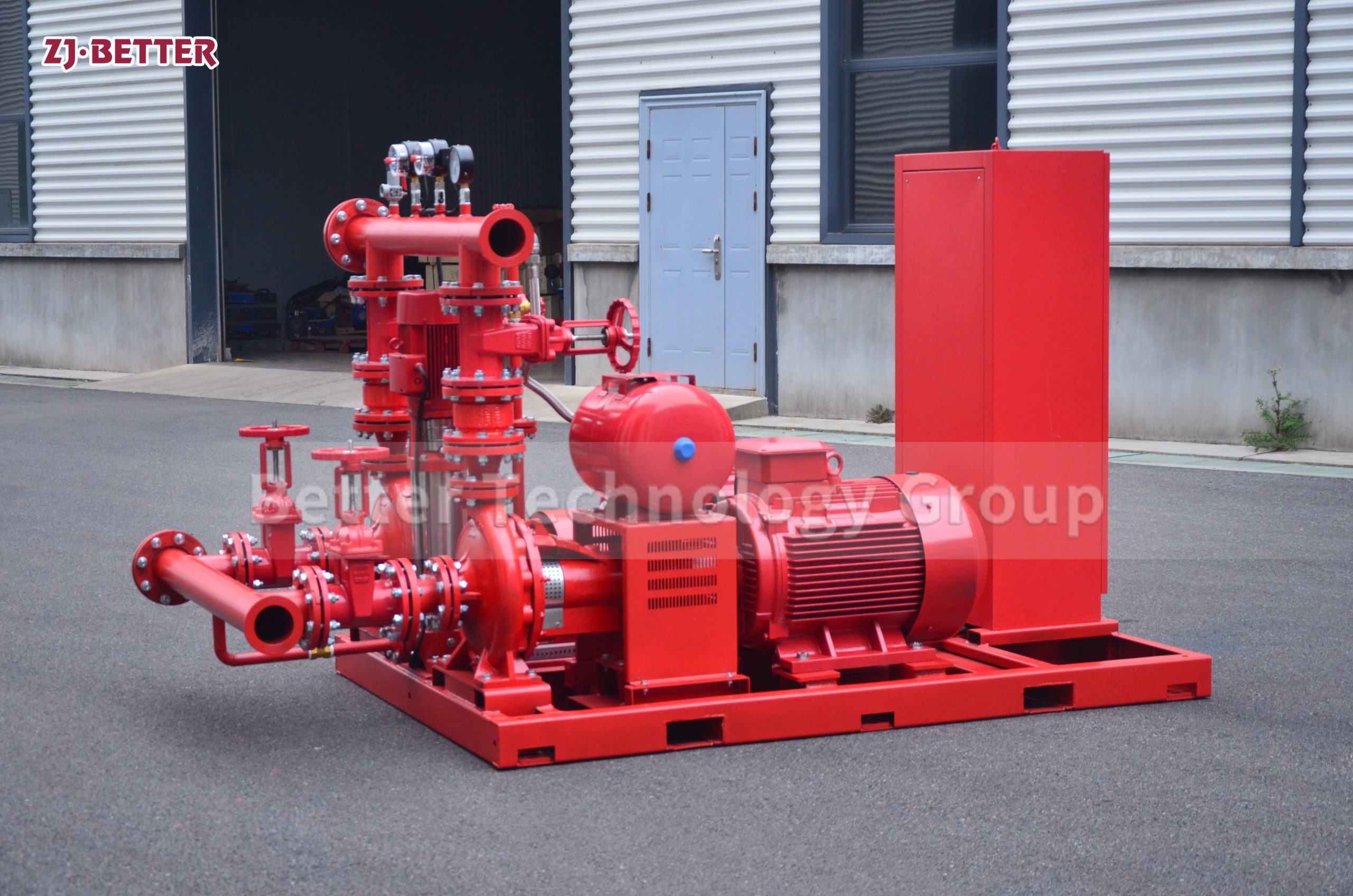

This highly efficient and reliable portable diesel fire pump is suitable for urban firefighting, industrial emergencies, and field rescue. It boasts powerful performance, high head, large flow rate, independent operation, and intelligent control, ensuring continuous water supply even in the absence of electricity. It is an ideal solution for responding to fires and providing emergency water supply.

Portable diesel engine fire pumps, as highly practical equipment in modern fire protection systems, have become key equipment in fire rescue, emergency water supply, industrial protection, and firefighting in remote areas due to their independent power drive, powerful water pressure output, and excellent mobility. These pumps use a diesel engine as their power source, do not rely on an external power system, and can operate independently in power outages, power failures, or harsh environments, ensuring the continuity and reliability of firefighting operations. With the diversification of fire protection needs and the increasing complexity of emergency scenarios, portable diesel engine fire pumps, thanks to their technological innovation and performance optimization, have gradually become an important choice for various emergency rescue units, factories, oil fields, mines, and municipal fire departments. The core advantages of this equipment are “powerful, rapid start-up, compact structure, convenient maintenance, and wide adaptability.” The diesel engine provides a high mechanical energy conversion rate, enabling the fire pump to generate a stable water flow with high head and large flow rate in a short time, thereby meeting the fire water supply needs of different locations. Whether for high-rise building water supply, industrial cooling, oil depot firefighting, or emergency water supply at forest, rural, or wildfire sites, portable diesel fire pumps demonstrate exceptional reliability and stability thanks to their high power output and long-term continuous operation. The equipment is designed with practicality and flexibility in emergency environments in mind. The pump body is made of high-strength, corrosion-resistant cast iron or alloy steel, possessing excellent pressure resistance and wear resistance, enabling stable operation even in high-temperature, high-humidity, and impurity-containing water conditions. The impeller undergoes a precision-balanced design, ensuring uniform water flow, low vibration, and low noise even at high speeds, effectively improving overall operating efficiency and extending equipment lifespan. The pump body and diesel engine are connected via a high-precision coupling, resulting in high energy transfer efficiency, a compact structure, and convenient installation and maintenance, making it particularly suitable for emergency scenarios requiring frequent relocation or temporary deployment. In terms of the power system, the diesel engine features low fuel consumption, high torque, and stable power output. By optimizing the combustion system and intake structure, the engine maintains high efficiency under various loads and possesses excellent cold-start performance, enabling rapid startup even in low-temperature or high-altitude environments, saving valuable time for fire rescue. Furthermore, the portable diesel fire pump is equipped with an advanced control system and safety protection devices, including automatic oil pressure alarm, coolant temperature monitoring, fuel level display, and fault self-diagnosis, ensuring safe and reliable operation over long periods. The control system offers both manual and automatic modes, allowing users to switch flexibly according to site conditions, enabling remote start, pressure monitoring, and automatic shutdown, greatly improving operational convenience and intelligence. In terms of performance, the portable diesel fire pump boasts significant advantages such as high head, large flow rate, and rapid start-up. Its rated flow rate ranges from 20 to 200 liters per second, and its head reaches 30 to 180 meters, meeting diverse fire protection needs in urban fire hydrant networks, industrial plants, and high-rise buildings. Due to its efficient hydraulic design and optimized flow channel structure, the pump experiences minimal hydraulic loss during operation, resulting in a high energy efficiency ratio and significant energy savings. Furthermore, this pump possesses strong self-priming capability and negative pressure start-up performance, enabling it to quickly generate stable suction and provide rapid water supply even under conditions of high suction head or unfavorable water source conditions. The portable diesel engine fire pump has extremely wide applicability. In municipal fire protection systems, it can serve as a main pump or emergency backup pump, ensuring the water supply system remains operational during power outages or equipment maintenance. In industrial settings such as chemical plants, power plants, and oil depots, it can be used as emergency cooling and fire extinguishing water supply equipment, preventing greater safety risks caused by fires or equipment overheating. In agricultural and rural areas, it can be used for fire prevention, irrigation, or drought relief. In special environments such as ports, docks, ships, tunnels, and mining areas, the portable diesel engine fire pump, with its mobility and independent drive characteristics, can be quickly deployed and put into use, greatly improving emergency response speed. This pump is also widely used in forest fire fighting, emergency rescue, and field operations; its lightweight unit structure and portable chassis design make transportation, handling, and on-site installation easier. Whether operated solo or in a team, deployment can be completed quickly to address sudden fires or water supply interruptions. Modern portable diesel fire pumps also prioritize energy efficiency and environmental performance. The new generation of engines has been optimized for combustion efficiency and emission control, meeting international environmental standards and reducing exhaust emissions and noise pollution, making them suitable for urban and indoor environments. Simultaneously, improved lubrication and cooling systems ensure the engine remains stable at low temperatures even under prolonged high-load operation, improving efficiency and extending the overall lifespan of the equipment. The modular design of the pump body facilitates maintenance; common wear parts such as seals, bearings, and impellers can be quickly replaced, significantly reducing later maintenance costs. With the development of intelligent manufacturing and industrial IoT technologies, the control systems of portable diesel fire pumps are gradually becoming digitalized and remotely monitored. Users can view real-time operating status, flow rate, pressure, fuel consumption, and alarm information through the control panel or remote terminal, enabling precise equipment management. This intelligent upgrade not only improves system operating efficiency but also helps users achieve predictive maintenance, preventing a decline in firefighting capabilities due to sudden failures. In terms of safety, the equipment design strictly adheres to international fire pump standards, featuring multiple safety mechanisms including overheat protection, low oil pressure shutdown, and anti-dry-run protection, ensuring stable operation even under extreme conditions. Structurally, it employs an anti-vibration base and reinforced frame, effectively absorbing vibrations and preventing mechanical displacement, making it particularly suitable for vehicle transport or use on uneven ground. Notably, the portable diesel fire pump exhibits excellent long-term reliability. Through a matched design of a high-efficiency transmission system and wear-resistant seals, the equipment can operate continuously for 8 to 12 hours with minimal performance degradation. The pump shaft is made of high-strength stainless steel, heat-treated and corrosion-resistant to resist corrosion from chlorine-containing or weakly acidic/alkaline water, ensuring the pump body maintains high efficiency over the long term. In conclusion, the portable diesel fire pump, with its powerful performance, flexible mobility, excellent durability, and intelligent control system, occupies an irreplaceable and vital position in modern fire protection. It is not only a highly efficient emergency water supply device but also a core power unit for protecting life and property. Whether responding to high-rise fires in cities, sudden industrial accidents, or emergency rescue missions in remote areas, this equipment provides sustained and powerful support to fire protection systems with stable water pressure, reliable performance, and efficient response speed. It represents the trend of modern fire protection equipment towards higher efficiency, intelligence, and energy conservation, and is an important direction and solid guarantee for future fire emergency equipment.