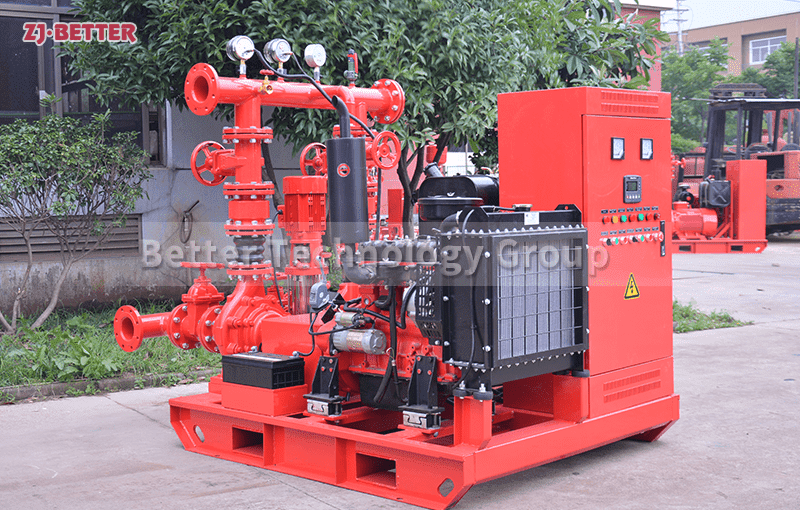

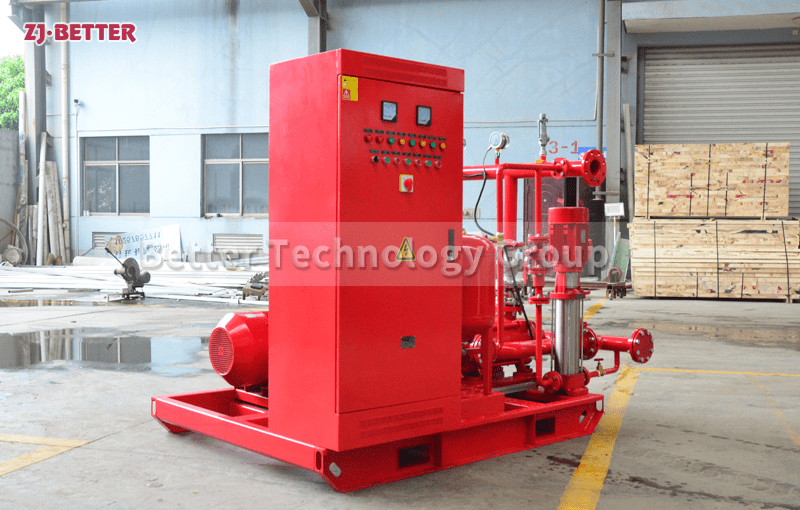

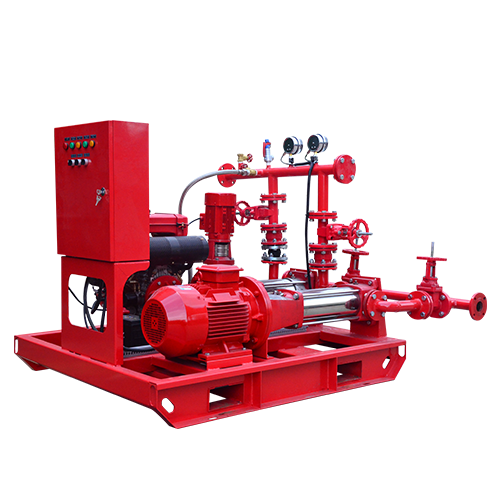

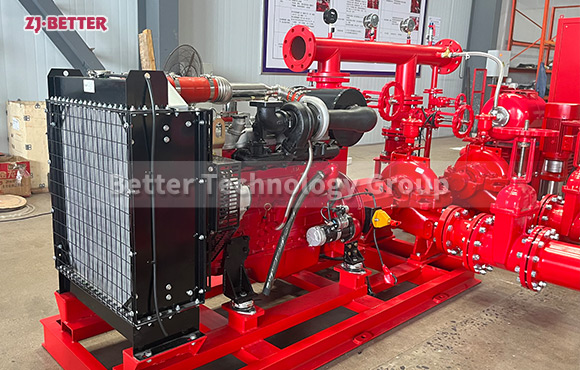

High-Efficiency Electric Fire Pump: The Core Power for Modern Fire Protection Systems

High-efficiency electric fire pumps are known for their stability, high head, and high flow rate, and offer advantages such as automatic control, energy saving, environmental friendliness, and easy maintenance. They are suitable for fire protection systems in high-rise buildings, factories, airports, and other facilities, ensuring rapid and reliable emergency water supply and providing efficient and safe firefighting support for various facilities.

As a crucial fire-fighting equipment in modern buildings, industrial plants, warehousing facilities, and municipal water supply systems, the performance and stability of electric fire pumps directly determine the response speed and fire-extinguishing capability of fire-fighting systems during emergency fires. High-efficiency electric fire pumps, with their advanced motor drive systems, precise hydraulic design, and reliable automatic control technology, have become an indispensable core power source in various fire-fighting systems. They provide strong support for various scenarios such as building fire protection, sprinkler systems, fire hydrant water supply, and emergency drainage with continuous and stable water flow output and high-lift water supply performance. The design concept of electric fire pumps stems from the dual requirements of high efficiency and high reliability. The pump body adopts a pressure-resistant and corrosion-resistant cast iron or stainless steel structure, and the impeller undergoes hydrodynamic optimization design to ensure maximum hydraulic efficiency under low energy consumption conditions. The motor is precisely matched, featuring rapid start-up, smooth operation, low noise, and low vibration, maintaining stable output under continuous high load operation, reducing mechanical wear and effectively extending the service life of the equipment. Compared to traditional diesel-powered fire pumps, electric fire pumps require no fuel supply during operation, are easier to operate, and have lower operating costs. They are particularly suitable for urban building complexes with stable power supplies, such as high-rise office buildings, shopping malls, subway stations, airports, hospitals, and industrial plants. Their automated control system enables intelligent start-up and shutdown, using pressure sensors and control cabinets for real-time monitoring. Once the pipeline pressure drops to a set value, the pump unit can automatically start within seconds, ensuring the fire protection system responds to fire alarms immediately, thus significantly improving fire extinguishing efficiency. In terms of performance, high-efficiency electric fire pumps offer a comprehensive performance of high flow rate, high head, and high stability. The flow rate of a single pump can be designed according to demand, ranging from tens of cubic meters per hour to thousands of cubic meters per hour, and the head can cover the water supply needs of buildings from low-rise to high-rise. Their hydraulic efficiency is generally between 75% and 85%. Through reasonable impeller curve design and inlet guide devices, water flow loss is greatly reduced, resulting in more stable output pressure and more uniform water distribution in sprinkler systems and fire hydrants. The sealing system of the electric fire pump is also an important component ensuring its performance. Employing mechanical or packing seal structures, the system prevents any form of liquid leakage under high pressure, ensuring safe operation and effectively preventing damage to the motor and other electrical components. The cooling system is typically designed with self-circulation or external cooling to prevent excessive motor temperature rise during prolonged operation, thus maintaining the pump unit in optimal working condition. Furthermore, the electrical control system of the electric fire pump is crucial for intelligent management. The control cabinet is equipped with start-up control, pressure display, alarm indication, and a remote monitoring interface, enabling linkage with building automation systems (BAS) or fire monitoring centers. The system supports manual, automatic, and remote operation modes, allowing for manual forced start in emergencies. This ensures that even with partial failures in the electrical control system, the fire pump can still be manually put into operation, providing dual protection for fire safety. To adapt to different environmental requirements, electric fire pumps offer diverse structural options. Common types include horizontal single-stage centrifugal pumps, vertical multistage pumps, end-suction pumps, and horizontal split-type pumps. Horizontal centrifugal pumps are compact in structure, easy to maintain, and suitable for locations with ample machine room space. Vertical multistage pumps, characterized by high head and small footprint, are suitable for high-rise buildings and fire pump rooms. End-suction pumps offer flexible inlet and outlet water arrangement, facilitating connection to fire piping systems. Depending on installation requirements, pump sets can be directly assembled with the control system, motor base, and coupling into an integrated structure. Each unit undergoes rigorous water pressure and performance testing before leaving the factory to ensure it meets national and international fire protection standards. The energy efficiency of electric fire pumps is one of their greatest advantages. Due to the use of high-efficiency motors and optimized hydraulic systems, their overall energy consumption is reduced by approximately 15% to 25% compared to traditional fire pumps, resulting in significant savings in operating costs over the long term. Furthermore, the motor-driven operation produces no exhaust emissions and consumes no fuel, aligning with modern green environmental protection concepts and facilitating use in enclosed or semi-enclosed spaces. Regarding system compatibility, electric fire pumps can be combined with pressure-stabilizing pumps, sprinkler pumps, diesel main pumps, and other equipment to form complete fire pump sets, creating a multi-stage water supply system. When the system detects a power outage or main pump failure, it can automatically switch to standby pump mode, achieving redundancy protection and ensuring the continuous water supply capacity of the entire fire protection system remains unaffected. Its applications are extremely wide, covering urban high-rise buildings, residential communities, underground garages, chemical plants, docks, warehousing bases, hospitals, airports, and other locations. Design parameters for different operating conditions can be customized according to customer needs to meet the actual requirements of different flow rates, pressures, and control methods. In terms of installation and maintenance, electric fire pumps have the advantages of simple structure and convenient disassembly and assembly. Routine maintenance mainly includes bearing lubrication, seal inspection, and electrical control system testing. The impeller, shaft seal, and guide shell inside the pump body adopt a replaceable structure design, significantly improving maintenance efficiency and reducing repair costs. To prevent performance degradation due to prolonged idleness, the control system can be set to perform periodic automatic trial runs, ensuring that the equipment maintains good start-up and operating performance even in non-fire conditions. From a reliability perspective, electric fire pumps have undergone long-term operational experiments and performance verification, maintaining stable output even in extreme environments, especially in high-temperature, high-humidity, and corrosive gas environments, where their durability is particularly outstanding. By employing high-quality materials and precision machining processes, the entire unit possesses excellent seismic resistance and long-term stability. Overall, the high-efficiency electric fire pump represents the modernization direction of fire water supply equipment technology. With its efficient power transmission, precise flow control, intelligent operation management, and energy-saving operating methods, it provides comprehensive, reliable, and durable power support for building fire protection systems. Whether in daily water supply operation or emergency fire-fighting situations, it provides a solid guarantee for people’s lives and property safety with its superior performance and stable quality.

管道泵(不锈钢304316L).jpg)