Understand the common control methods of diesel engine fire pumps

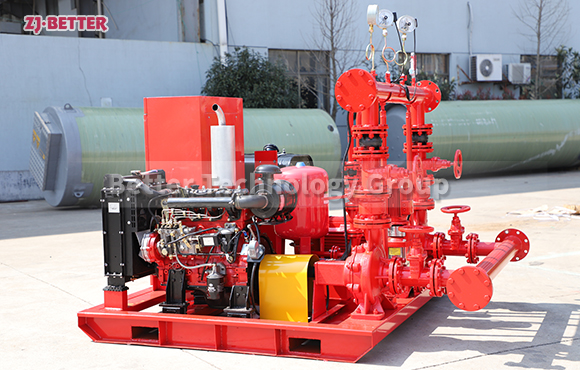

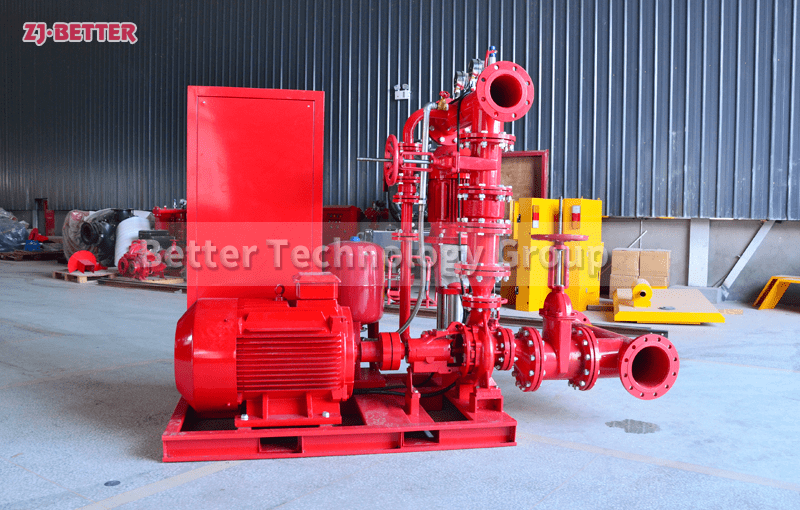

According to the technical information of diesel engine fire pumps, diesel engine fire pumps have been widely used in environmental protection, water treatment, fire protection and other departments to pump various liquids. They are ideal pumps for creating civilized workshops and factories without leakage and pollution.

Generally speaking, the common control methods of diesel engine fire pumps mainly include:

1. Manual control: The diesel engine fire pump is manually pressed on the control panel button, and the operation process is automatically completed by the preset program. the

2. Automatic control: When the equipment is affected by fire/pipe pressure or other automatic control signals, the response starts/stops. the

3. Remote control: The computer realizes remote monitoring, remote control, remote communication, and remote adjustment through the communication network.