The Secret to Reliable Fire Protection: Advantages of Intelligent Pressure Tanks

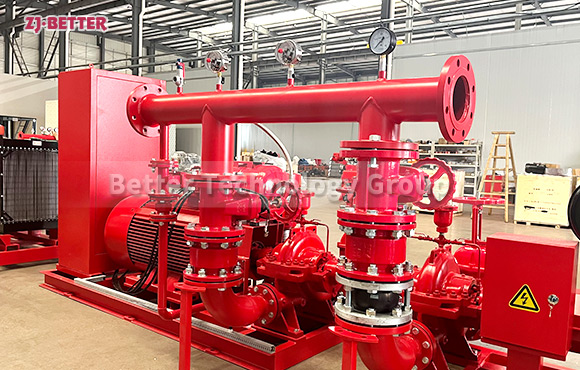

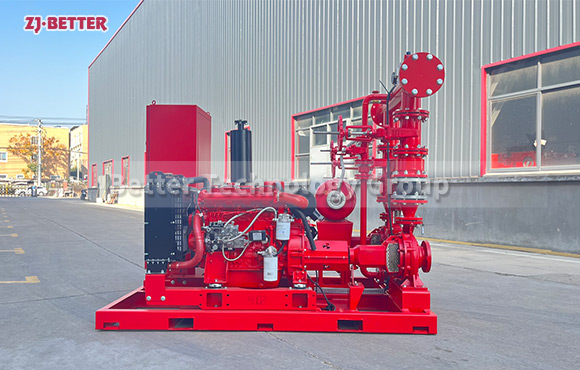

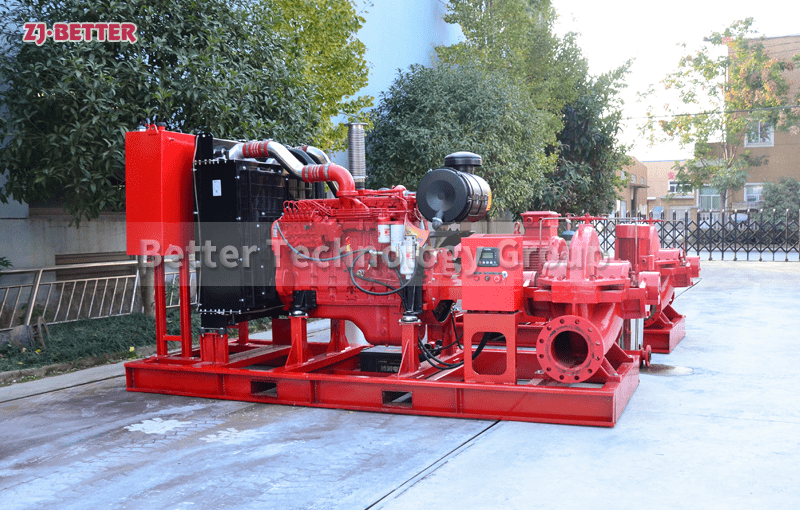

The intelligent pressure stabilizing tank is a high-performance firefighting water supply device featuring precise pressure control, energy-efficient operation, and automated management capabilities. Utilizing an advanced sensor system and pressure-resistant tank design, it ensures consistent water pressure within fire suppression systems, enabling rapid response and safe operation. Widely deployed in high-rise buildings, industrial parks, and commercial complexes, it serves as an ideal solution for enhancing the reliability and efficiency of fire protection systems.

In modern fire protection water supply systems, the pressure tank serves as an indispensable key component. It not only maintains stable system pressure but also directly impacts the response speed, operational efficiency, and safety reliability of the entire fire protection system. With continuous technological advancements, traditional pressure tanks are gradually being replaced by intelligent, modular pressure tank systems. These products, featuring precise pressure control, automated operation, and energy-efficient design, are becoming core equipment in various fire protection projects. Intelligent pressure tanks operate on the principle of dual-medium regulation—gas and water. Within a sealed container, compressed air and water interact repeatedly to maintain a constant working pressure in the system, ensuring the fire protection network sustains its preset pressure level at all times. Should system pressure drop occur, the pressure tank automatically compensates by activating the pressurization device, guaranteeing sprinklers, fire hydrants, or jet systems function immediately with “zero-delay” response. This response speed is unmatched by traditional manual or delayed systems. A key advantage of the smart pressure tank lies in its high-precision pressure control system. The device typically incorporates a high-sensitivity pressure sensor and a microprocessor control module, enabling real-time monitoring of system pressure changes, intelligent judgment, and automatic start/stop regulation. Unlike traditional pressure stabilizers reliant on manual adjustments or mechanical controls, the smart tank utilizes electronic feedback signals to prevent system instability caused by delayed human intervention or excessive pressure fluctuations. This control method not only ensures continuous pressure stability but also extends the service life of pipelines, valves, and pump assemblies, enhancing the overall operational reliability of the fire protection system. Additionally, the smart pressure tank delivers significant energy savings. By precisely controlling start-stop frequency, they effectively reduce pump runtime, preventing energy waste from frequent cycling. Some models incorporate variable frequency drive systems that dynamically adjust output power based on actual water demand, minimizing energy consumption while meeting pressure requirements. This energy-efficient operation not only complies with modern building energy standards but also substantially lowers operating costs, making it ideal for locations requiring continuous long-term operation, such as high-rise buildings, industrial parks, and commercial complexes. Structurally, modern pressure tanks are constructed from pressure-resistant carbon steel or stainless steel. They incorporate high-strength rubber diaphragms or air bladders that completely separate gas from water, preventing water contamination and enhancing system stability. The tank bodies undergo anti-corrosion treatment and high-temperature baking paint processes, enabling long-term operation in humid, dusty, or high-temperature environments without degradation. Additionally, the equipment features a compact structure with a small footprint and easy installation. It can be flexibly configured for use in pump rooms, basements, or integrated modules, significantly enhancing installation flexibility. Intelligent pressure stabilizing tanks also incorporate comprehensive safety protection functions, including overpressure protection, low-water protection, automatic venting, and automatic alarm systems. When abnormal pressure or gas leaks occur in the system, the control system immediately triggers an alarm or automatically shuts down, ensuring the safe operation of the equipment and system. Certain models also support remote monitoring capabilities, connecting to fire control centers via digital communication interfaces for real-time data acquisition and remote control. This not only enables managers to monitor operational status but also provides early warnings of potential faults, reducing maintenance risks and labor costs. Beyond technical and structural advantages, smart pressure stabilizing tanks excel in longevity and maintenance. Crafted from high-quality materials with precision manufacturing, these units require minimal routine maintenance—only periodic checks of pressure and valve status are needed, keeping upkeep costs exceptionally low. Unlike traditional stabilization methods, they lack complex mechanical wear components, typically achieving service lives exceeding 10 years. This combination of extended lifespan and low maintenance makes smart pressure stabilizing tanks a highly cost-effective choice for fire protection systems. Performance-wise, the smart pressure tank operates across a broad working pressure range, accommodating diverse system environments from 0.6MPa to 2.5MPa. Capacity and control parameters can be customized to meet specific fire protection system requirements. Its exceptional adaptability allows deployment in sprinkler systems, fire hydrant systems, foam fire suppression systems, as well as industrial cooling, domestic water supply, and other applications demanding constant pressure water delivery. This multifunctional versatility has led to widespread adoption in building fire protection projects, industrial complexes, energy facilities, and transportation hubs. During fire emergencies, the pressure tank ensures the necessary initial water pressure is available before the main pump activates, enabling sprinkler heads to open immediately for fire suppression. This “seamless transition” capability is crucial for rapid fire system response. Particularly during nighttime operations or power fluctuations, the intelligent pressure tank can still fulfill its initial pressurization task using stored gas energy, buying critical response time for the system. Working in tandem with primary and backup pumps, it forms an efficient, reliable automated water supply network, ensuring swift and safe activation during any fire scenario. Notably, the control system of the intelligent pressure tank features self-learning capabilities. It automatically optimizes start-up logic and pressure compensation parameters based on operational data, making the system smarter over time as it adapts to specific usage environments. This “adaptive control” technology not only enhances system stability but also reduces the complexity of manual debugging, enabling more intelligent and efficient equipment operation. In terms of appearance, the modern intelligent pressure tank system features a compact and aesthetically pleasing design with rational piping layout and clear wiring. It is equipped with an intuitive control panel and digital display monitoring interface, facilitating system status monitoring for operators. Its modular design enables seamless integration with electrical control cabinets, pump sets, and piping systems, forming a complete integrated fire protection pressure stabilization system. Users can configure combinations based on actual project requirements to achieve customized solutions. The broad application value of the intelligent pressure tank extends beyond fire protection systems, playing a significant role in other fluid control scenarios. For instance, in building domestic water supply systems, it effectively prevents water hammer effects and balances pressure fluctuations in the pipeline network. In industrial cooling systems, it ensures stable water supply to equipment, preventing damage caused by excessive temperatures. Thus, this device is not merely fire protection equipment but a versatile, high-performance pressure control solution applicable across multiple fields. Overall, the intelligent pressure tank delivers robust assurance for modern fire protection system safety through its integrated performance: high stability, rapid response, energy efficiency, environmental friendliness, and intelligent control. It achieves industry-leading precision in pressure regulation, operational intelligence, and system security, making it an ideal choice for upgrading existing fire protection systems and new construction projects in modern buildings. By implementing the intelligent pressure tank, users gain not only stable and reliable water supply assurance but also achieve more efficient, energy-saving, and secure fire protection system operation, providing robust technical support for safeguarding personnel and property.