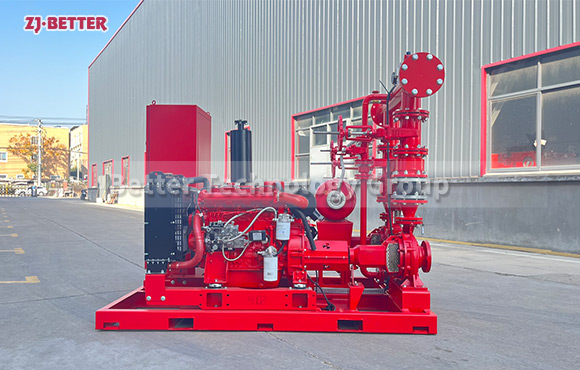

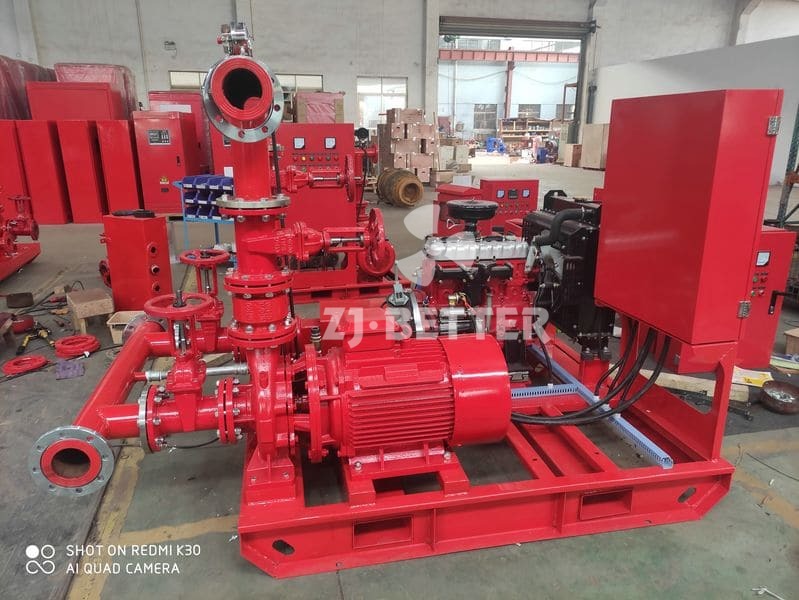

Vertical In-Line Fire Pump Solution for Industrial and Civil Fire Projects

This vertical pipeline fire pump, designed for industrial and civil fire protection projects, features a compact vertical structure and efficient hydraulic design. It boasts rapid start-up, stable operation, high head, and continuous water supply capacity, making it suitable for fire hydrant and sprinkler fire protection systems and meeting the fire water supply needs of various buildings.

This vertical pipeline fire pump configuration solution for industrial and civil fire protection engineering is a professional fire water supply equipment developed and designed to meet the ever-increasing requirements of modern building fire protection systems in terms of safety, stability, and space adaptability. The overall design adopts a vertical pipeline structure, with the motor and pump body coaxially directly connected, significantly reducing the floor space required. This gives it a significant installation advantage in high-rise buildings, underground pump rooms, industrial plants with limited equipment space, and mixed-use projects, while effectively reducing foundation construction and pipeline modification costs. The hydraulic performance design of this vertical pipeline fire pump fully incorporates the core requirements of fire protection systems: “high head, rapid response, and continuous water supply.” By optimizing the impeller profile and flow channel structure, the water flow inside the pump body is more stable, reducing hydraulic losses and energy waste. This achieves high-efficiency output under rated operating conditions, ensuring that fire hydrant systems and automatic sprinkler systems can quickly establish stable water pressure and provide continuous water supply in emergency situations. The pump body boasts a compact yet rigid structure. Key pressure-bearing components are constructed from high-strength materials, exhibiting excellent pressure resistance and impact resistance. This allows it to withstand complex operating conditions in fire protection systems, such as instantaneous high pressure, water hammer, and frequent start-stop cycles, significantly enhancing the overall safety and service life of the unit. The drive system utilizes a dedicated, high-reliability motor, characterized by high starting torque, stable operation, and reasonable temperature rise control. Even after long periods of standby, sudden starts or continuous operation maintain stable output, preventing impacts on the overall effectiveness of the fire protection system due to start-up failures or insufficient power. The vertical design keeps the motor away from areas with surface water, effectively reducing the risk of moisture absorption and further enhancing the equipment’s applicability in underground pump rooms and high-humidity environments. The sealing system employs mature and reliable mechanical seals or combined seal solutions, ensuring sealing performance while balancing ease of maintenance. This effectively prevents leakage during operation, ensuring the fire pump maintains optimal working condition even during long periods of standby. This vertical pipeline fire pump also excels in vibration and noise control. The coaxial direct-drive design of the motor and pump body reduces eccentricity and vibration sources from intermediate transmission components, resulting in smoother operation and facilitating long-term continuous operation. It also meets the noise control requirements of modern buildings for machine rooms. In terms of system integration, this configuration can flexibly connect to fire control cabinets, pressure control systems, and automatic inspection devices, enabling multiple operating modes such as automatic start, manual control, and remote linkage. When the pipeline pressure drops or a fire signal is received, the fire pump can quickly respond and enter a stable operating state. It also features multiple protection functions including overload, phase loss, and short circuit protection, providing reliable protection for the entire fire water supply system. This product also offers significant advantages in installation and maintenance. The inlet and outlet pipe diameters are aligned with the pipeline centerline, reducing bends and complex pipe connections, resulting in high installation efficiency, low system resistance, and allowing for maintenance without extensive pipe disassembly, significantly reducing operation and maintenance costs. Tailored to the specific needs of various industrial and civil fire protection projects, this vertical pipeline fire pump configuration allows for flexible combinations in terms of flow rate, head, power, and interface specifications. It is widely applicable to various scenarios including office buildings, residential communities, commercial complexes, hospitals, schools, warehousing and logistics centers, and industrial plants. Each unit undergoes rigorous performance testing and quality inspection before leaving the factory to ensure that its hydraulic performance, structural strength, and operational stability meet the high standards required by fire protection systems. In practical engineering applications, this specialized vertical pipeline fire pump for industrial and civil fire protection projects, with its high efficiency, strong stability, compact structure, and excellent system adaptability, has become a crucial solution in modern fire water supply systems that balances performance and space utilization, providing solid support for building safe, reliable, and sustainable fire protection systems for various buildings and industrial projects.