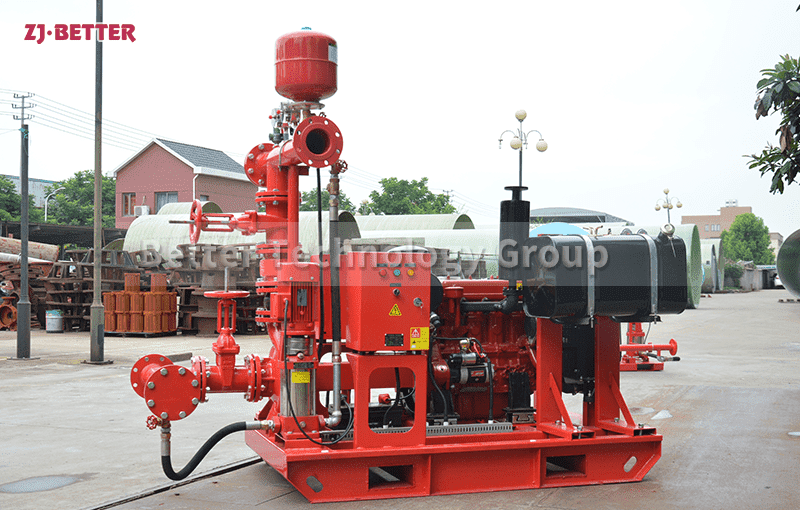

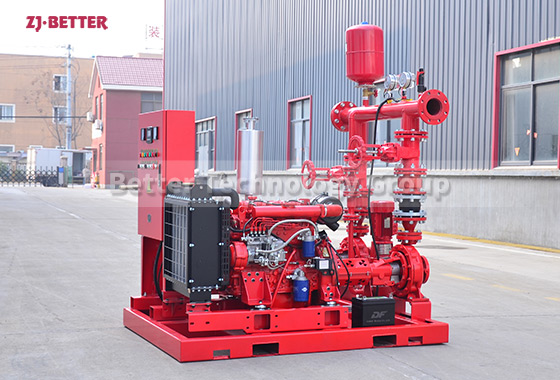

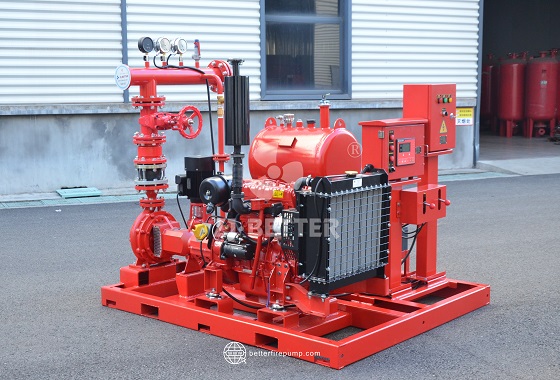

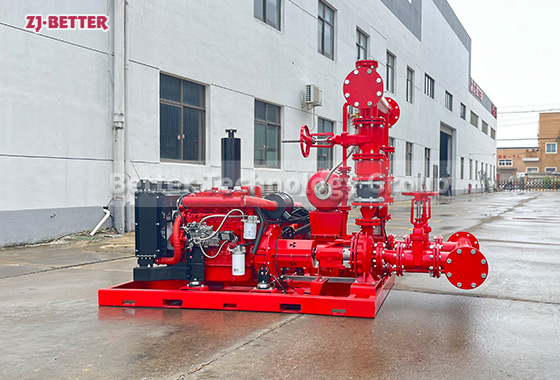

Fire Jockey Pump and Air Tank Combination System: The Perfect Balance of Continuous Pressure and Energy Efficiency

The fire jockey pump and air tank combination system ensures stable fire water pressure through intelligent control and air pressure stabilization. Featuring energy efficiency, low noise, automatic start-stop, and remote monitoring, it offers compact design and easy installation—ideal for high-rise buildings, industrial facilities, and logistics centers as a reliable modern fire pressure maintenance solution.

The combined fire protection pressure-stabilizing pump and pressure tank system is a highly efficient pressure-stabilizing device designed specifically for modern building and industrial fire protection systems. It maintains continuous, stable water pressure within the fire protection network, ensuring rapid activation of fire pumps and sufficient water flow in the event of a fire, thereby achieving safe, efficient, and energy-efficient fire water supply management. This system typically consists of a pressure-stabilizing pump, pressure tank, electronic control system, piping components, and auxiliary equipment. Through scientific configuration and precise calibration, it consistently maintains a set pressure range, whether the fire protection system is in static standby or dynamic operation. This prevents water hammer and equipment misactivation caused by pressure fluctuations, ensuring the long-term stability of the entire fire protection system. The synergy between the pressure-stabilizing pump and pressure tank is the core advantage of this system. The pressure tank stores a constant amount of compressed air, forming an air-water interface with water. When the network pressure drops, the gas expands, pushing the water inside the tank to automatically compensate for the pressure, thereby maintaining system balance. If the pressure continues to drop to a set lower limit, the pressure-stabilizing pump automatically activates, quickly restoring the pressure to the normal range, and then automatically stops, achieving fully automated cyclic control. This design not only significantly reduces the main pump’s starting frequency, extending the service life of the main pump and electrical equipment, but also reduces energy consumption and system maintenance costs. The system utilizes a high-performance vertical multi-stage centrifugal pressure-stabilizing pump or horizontal centrifugal pump, characterized by high flow, high head, low noise, and minimal vibration. The pump body and impeller are constructed of high-quality stainless steel or corrosion-resistant alloys to ensure mechanical strength and durability during long-term operation. The motor is equipped with an efficient and energy-saving drive system that automatically adjusts start and stop according to pressure changes, providing fast response and stable and reliable operation. The pressure tank is constructed of welded carbon steel or stainless steel, lined with an anti-corrosion coating, and equipped with a high-strength diaphragm or air bladder to prevent gas-water mixing, thereby improving gas utilization and the tank’s service life. The tank design complies with national pressure vessel standards, offering excellent pressure resistance, a high safety factor, and adaptability to a variety of complex environmental conditions. The control system, the intelligent core of the entire system, utilizes advanced PLC control technology and a pressure sensor monitoring module to enable real-time data acquisition and automatic adjustment. The system automatically starts and stops the pressure-stabilizing pump within a set pressure range, offering both manual and automatic modes. It also incorporates multiple safety features, including phase loss, overload, short circuit, overvoltage, undervoltage, and dry-run protection, ensuring safe operation under various operating conditions. Some systems also feature an optional intelligent remote monitoring module, which connects to a fire monitoring center via an IoT platform. This allows for remote start-stop control, parameter adjustment, operation logging, and alarm information upload, enabling management personnel to monitor equipment operating status at all times, significantly enhancing the intelligence and reliability of the fire protection system. The combined fire protection pressure-stabilizing pump and air pressure tank system excels in energy conservation and environmental protection. Traditional fire protection piping networks lack stable pressure-regulating devices, often leading to frequent startup of the main pump, which not only increases energy consumption but also accelerates equipment wear. The pressure-stabilizing system, combining an air pressure tank with a low-power pressure-stabilizing pump, maintains pressure balance during extended standby periods, activating only briefly when necessary, significantly reducing energy consumption. Furthermore, the system operates with low noise and vibration, requiring no additional soundproofing, meeting modern green building energy-saving standards. Its sealed structure also effectively prevents moisture leakage and secondary pollution, making it suitable for locations with stringent environmental requirements. The system is also extremely easy to install and maintain. Its modular design minimizes footprint and allows for flexible layout based on site conditions. All components feature standardized interfaces, requiring only the connection of inlet and outlet pipes, power supply, and signal cables for installation, reducing construction time and costs. Each unit undergoes rigorous pressure and performance testing before shipment to ensure stable operation on-site. Regarding maintenance, the control cabinet features fault self-diagnosis and alarms, providing real-time status updates and potential hazards, enabling management to promptly troubleshoot issues. The pressure tank is equipped with access ports and a pressure gauge for convenient regular inspection and maintenance. The pressure-stabilizing pump utilizes a mechanical seal and lubrication-free design, resulting in virtually leak-free operation and minimal maintenance. A key feature of this system is its wide range of applications. It can be used in fire water supply systems in various buildings, including high-rise residential buildings, office buildings, shopping malls, hospitals, schools, subway stations, and underground garages. It can also be widely used in industrial and mining enterprises, petrochemical facilities, storage and logistics centers, power plants, and other locations requiring stable water pressure. Whether serving as a supplementary pressure-stabilizing unit for the main fire protection system or as a standalone, small-scale fire water source management device, it plays a vital role. In some specialized environments, such as those with high temperature, high humidity, or corrosive environments, explosion-proof motors and stainless steel pressure tanks can be used to meet specific operating requirements. From a safety perspective, the combined fire protection pressure-stabilizing pump and pressure tank system offers exceptional reliability. Even in the event of a power outage or electrical control failure, the pressure tank’s stored compressed energy can maintain system pressure for a short period of time, ensuring that fire protection facilities can continue to deliver water in an emergency and buying valuable time for subsequent main pump activation. Furthermore, the pressure-stabilizing system’s intelligent alarm function instantly notifies management of abnormal pressure, preventing fire protection system failure due to insufficient pressure and thus comprehensively enhancing the building’s fire safety rating. Overall, the combined fire protection pressure-stabilizing pump and pressure tank system, with its high efficiency, low energy consumption, intelligent design, strong safety, and easy maintenance, has become an indispensable component of modern fire water supply systems. It not only optimizes the operational efficiency of the entire fire protection network, reducing energy consumption and maintenance costs, but also provides stable pressure for the activation of the fire pump group at critical moments, ensuring that the fire extinguishing system can respond to fires immediately. As fire-fighting equipment develops towards automation and intelligence, this combined voltage stabilization system will gradually become the standard configuration of future fire-fighting projects, not only providing solid technical support for building fire protection, but also contributing strong impetus to the construction of industrial safety and urban protection systems.