Heavy-Duty Fire Pump Equipment for Oil and Gas Industry Applications

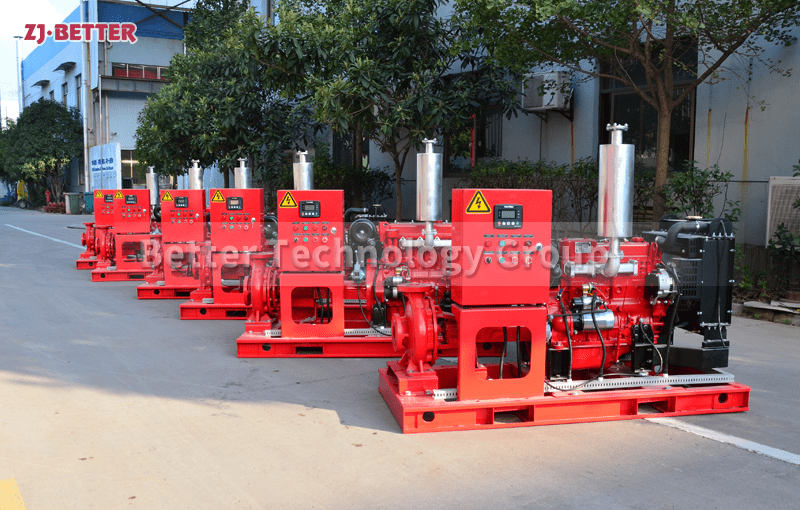

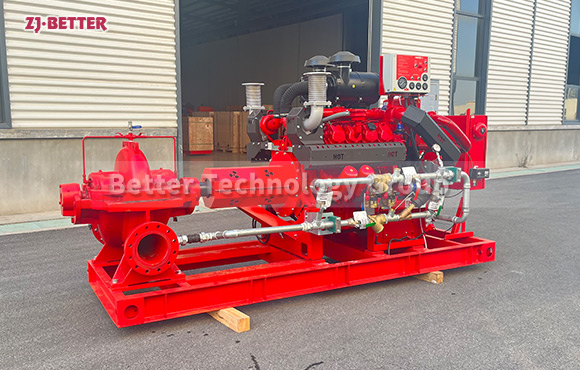

Heavy-duty fire pump equipment is designed specifically for the oil and gas industry. It features high flow, high head, corrosion resistance, and intelligent control. It can adapt to extreme environments and ensure long-term stable operation, providing reliable fire safety solutions for oil fields, refineries, storage and transportation stations, and offshore platforms.

In the oil and gas industry, safety is at the core of all operations, and fire risk is a hidden danger that the industry cannot ignore. Therefore, selecting a set of heavy-duty fire pump equipment with reliable performance, sturdy structure, and stable operation has become a vital part of ensuring production safety and emergency response capabilities in oil and gas fields, refineries, storage and transportation stations, and offshore platforms. With its strong power, long-term operation, durable materials, and intelligent control systems, heavy-duty fire pump equipment can provide a continuous supply of firefighting water support in complex, high-risk, and high-load environments, ensuring the safe operation of critical energy facilities. Fire pumps in the oil and gas industry differ from ordinary building fire protection systems. They must meet higher performance standards and be able to operate stably under extreme conditions. Heavy-duty fire pumps typically utilize a high-power drive system, supporting both electric and diesel engine configurations to ensure reliable water supply during power outages. The pump body and flow-through components are often constructed with high-strength, wear-resistant alloys and treated with corrosion-resistant coatings to resist corrosion and wear in oil and gas environments. Their design carefully considers flow and pressure, enabling them to maintain stable pressure output even during high-volume firefighting and long-distance water delivery, thus meeting the emergency water needs of locations such as petrochemical plants, tank farms, and oil and gas terminals. In terms of performance advantages, heavy-duty fire pumps offer exceptionally high flow rates, with a single pump unit capable of delivering over 10,000 cubic meters per hour. This allows them to rapidly deliver sufficient water for large-scale fires, providing robust hydraulic support for foam extinguishing systems, sprinkler systems, and fire hydrant networks. Furthermore, these pumps operate at high lift, maintaining stable pressure within complex pipe networks and multi-tiered distribution systems, ensuring adequate water supply to remote sprinklers and elevated storage tanks. Their specially optimized powertrain utilizes a high-efficiency turbocharged diesel engine or a high-power electric motor, coupled with an automatic control unit, enabling fast startup and continuous operation, meeting the demands of long, uninterrupted operation. Heavy-duty fire pumps emphasize modularity and overall strength in their structural design. The base frame is welded from thick-walled steel, offering vibration and impact resistance, enabling them to withstand the frequent operation and transportation at oil and gas production sites. The impeller, shaft, and sealing system within the pump body are precision-machined to ensure low vibration and noise even at high speeds, extending equipment life and reducing maintenance costs. To meet the high safety requirements of the oil and gas industry, heavy-duty fire pumps are often equipped with intelligent monitoring and automatic protection features. The operating panel integrates data from multiple sensors, including pressure, flow, temperature, and vibration, enabling real-time monitoring of operating status. In the event of anomalies such as insufficient water pressure, excessive oil temperature, or excessive vibration, the system automatically generates an alarm and initiates protective measures, preventing equipment damage or escalating faults and ensuring the fire protection system remains operational. Furthermore, some equipment can seamlessly integrate with the plant’s DCS or SCADA system for remote monitoring and centralized management, significantly enhancing operational convenience. In terms of environmental adaptability, heavy-duty fire pumps are capable of stable operation in harsh conditions, including high and low temperatures, humidity, dust, and marine salt spray. Whether operating in scorching desert oil fields, frigid Arctic drilling platforms, or humid, salty offshore oil platforms, these equipment ensures reliable startup and continuous operation, providing a solid foundation for fire safety in extreme environments. Furthermore, to meet environmental and energy conservation requirements, modern heavy-duty fire pumps prioritize energy efficiency and emissions. They utilize low-fuel-consumption engines and high-efficiency hydraulic designs, reducing energy consumption and operating costs while complying with international environmental standards, helping companies achieve their green development goals. Heavy-duty fire pumps have a wide range of applications. In onshore petrochemical parks, they serve as the main fire pump, providing a stable and reliable fire water supply for the entire plant. In oil and gas storage tank areas, they enable rapid startup and high-flow water supply, collaborating with foam systems to control large-scale liquid fires. At natural gas liquefaction stations, they ensure safe operation in low-temperature environments. On offshore oil platforms, they serve as key firefighting equipment, ensuring the platform’s fire response capabilities in isolated environments. For this reason, heavy-duty fire pumps have become a core component of fire safety systems in the global oil and gas industry. Overall, with their high flow and head, rugged construction, intelligent control, strong environmental adaptability, and high energy efficiency, heavy-duty fire pumps perfectly meet the fire safety needs of the oil and gas industry, providing reliable fire response capabilities for a wide range of complex locations. This not only enhances enterprise safety and security, but also effectively reduces the economic losses and environmental impacts caused by fire risks. With the development of the oil and gas industry and the improvement of safety standards, heavy-duty fire pumps will play an increasingly important role in the future, providing strong support for the safe operations of the global energy industry.