The high flow single-stage centrifugal pump is a device specifically designed for applications that require large flow rates and high efficiency in water supply systems, widely used in clean water and firefighting water supply fields. Due to its simple structure, easy maintenance, and stable operation, this type of pump system has become the preferred choice for many industrial and building projects, especially in places where water supply stability and reliability are critically important, such as commercial buildings, industrial plants, firefighting systems, and agricultural irrigation. The single-stage centrifugal pump works by rotating a series of high-speed impellers to transport water through the pump body and pressurize it, thus achieving the purpose of fluid delivery. Its main advantage lies in its simple structure design and efficient energy conversion, making it especially suitable for applications with high water flow and relatively low head requirements. The working principle involves the electric motor driving the impeller to rotate, generating centrifugal force, which draws the liquid from the pump’s inlet and accelerates it before discharging it at higher pressure from the outlet. This ensures that large amounts of liquid are efficiently and rapidly transported to the intended destination.

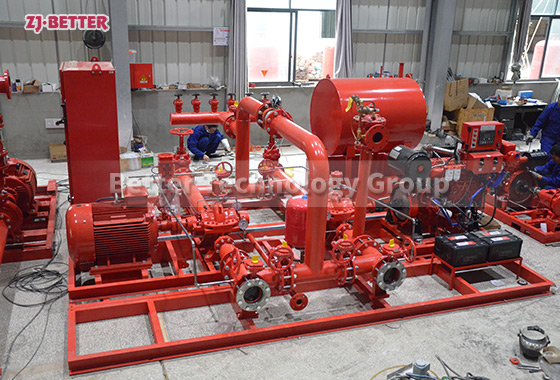

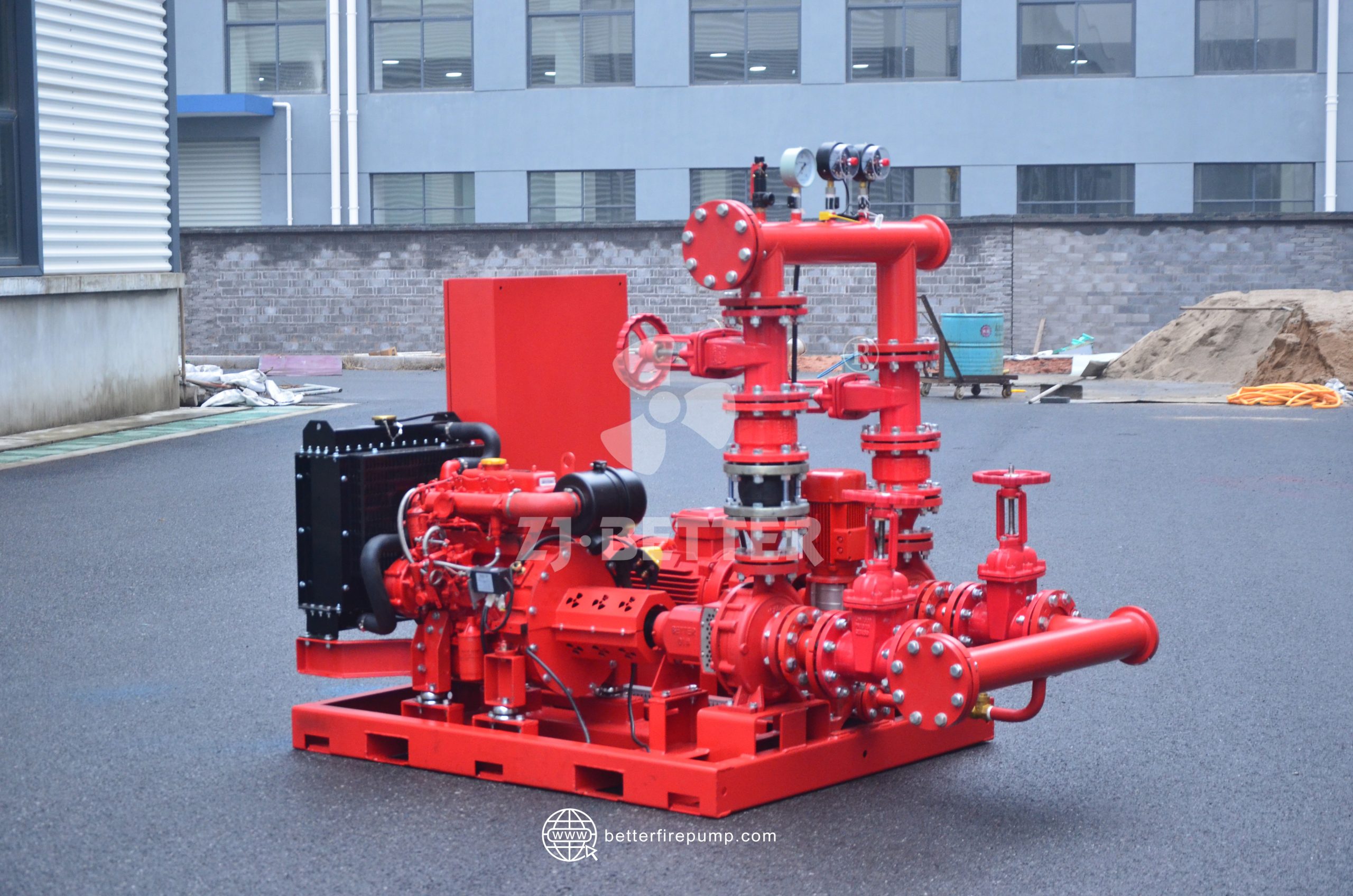

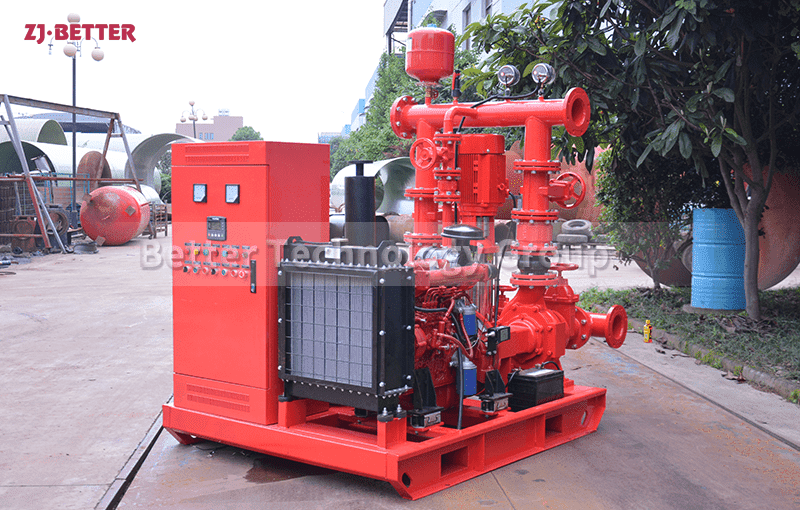

The flow rate and head of the single-stage centrifugal pump are generally achieved through the design of the pump body and impeller. The impeller, being the key component, directly affects the pump’s working efficiency and flow output. High-flow single-stage centrifugal pumps typically adopt large-diameter impeller designs, capable of handling substantial water flow while also reducing resistance, optimizing the pump’s flow output. This design not only ensures efficient operation but also effectively reduces energy consumption, lowering operational costs. For firefighting water supply applications, this type of pump can quickly start up at the beginning of a fire and continuously provide stable pressure and flow during the entire firefighting process. Whether in industrial parks or large buildings, it ensures that the firefighting water source is uninterrupted due to pump performance issues, providing timely water supply to support firefighting operations.

In clean water supply systems, the single-stage centrifugal pump performs excellently. It is widely used in municipal water supply, irrigation systems, and cooling water systems, providing stable and reliable water flow support to these places. The pump, through its highly efficient energy conversion, can supply large amounts of water while minimizing energy waste, ensuring long-term stable operation and reducing downtime and maintenance costs. In industrial production, many high-flow cooling systems and liquid transfer systems rely on this type of pump to ensure that water flow within the system is maintained at the proper level to prevent equipment failure due to water shortages or flow disruptions.

From the installation and maintenance perspective, the single-stage centrifugal pump offers significant advantages. First, the pump has a relatively simple structure, with the main components, such as the pump body, impeller, and motor, being easy to install and remove, making regular maintenance and troubleshooting faster. Routine maintenance mainly involves cleaning the impeller, replacing seals, and checking bearings, all of which can be completed in a short amount of time, reducing equipment downtime and improving overall system efficiency. At the same time, the single-stage centrifugal pump is designed with good sealing performance, preventing water leakage and other issues, improving the working efficiency and safety of the system. For large-scale systems, the installation method and lifespan of the pump group are also critical, and the design of the single-stage centrifugal pump ensures that the pump body remains stable during long-term use, minimizing the risk of failure due to equipment aging or wear.

In operation, the single-stage centrifugal pump performs excellently in terms of energy efficiency. The pump is driven by a highly efficient motor, and the pump body is designed to minimize energy loss, maximizing the pump’s output efficiency. This high-efficiency design is particularly important for systems that run for extended periods, as it effectively reduces energy costs and extends the pump group’s service life. In firefighting water supply applications, especially in high-rise buildings, the single-stage centrifugal pump not only ensures stable water pressure for firefighting but also prevents system failures due to unstable flow, improving the overall reliability of the firefighting system.

For most construction projects, the use of the single-stage centrifugal pump can significantly reduce construction costs. Compared to multi-stage centrifugal pumps, single-stage centrifugal pumps have simpler structures, lower manufacturing and installation costs, and occupy less installation space, making them ideal for buildings with tight space conditions. Its design ensures that it can meet large flow requirements while also adjusting working parameters flexibly according to actual needs, making it highly efficient in various environments. In addition, the installation process of the single-stage centrifugal pump is relatively simple, reducing the workload and time for construction units, making it suitable for projects of different scales.

In addition to standard clean water and firefighting applications, the single-stage centrifugal pump has a wide range of uses in various industries, including industrial, agricultural, and other fields. In industry, the single-stage centrifugal pump is typically used for cooling water circulation, liquid transfer, wastewater treatment, and other scenarios, ensuring the normal operation of industrial production systems. In agriculture, it is widely used in irrigation systems and reservoir drainage, ensuring water supply for farmland. For some special fluid transfer requirements, the single-stage centrifugal pump can also be customized based on customer needs to provide more precise water flow and pressure control, meeting the specific requirements of various industries.

In summary, the high-flow single-stage centrifugal pump, as an efficient, reliable, and easy-to-maintain water supply device, has been widely applied in various fields, especially in clean water and firefighting water supply. Its high flow, high head, simple design, and low energy consumption characteristics make it one of the most popular water supply solutions in industrial and construction applications. Whether in the daily water supply system of buildings or in emergency water supply systems during a fire, the single-stage centrifugal pump plays a critical role in ensuring the success of firefighting operations and the smooth completion of water supply needs.