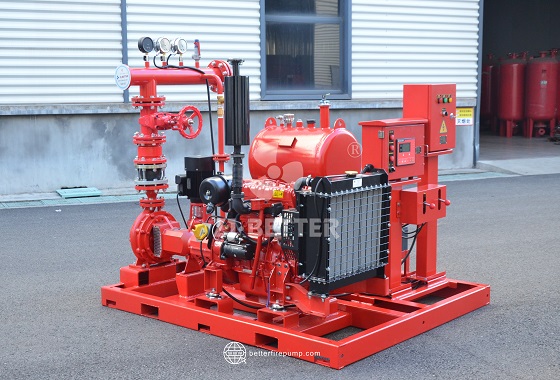

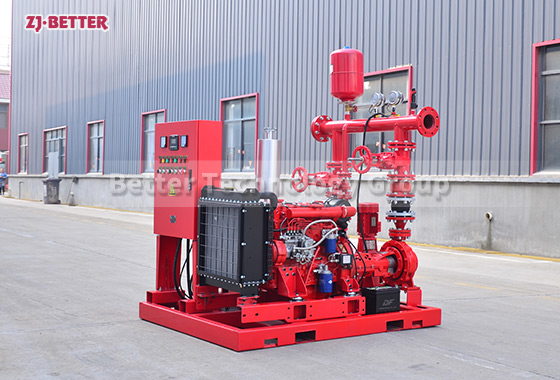

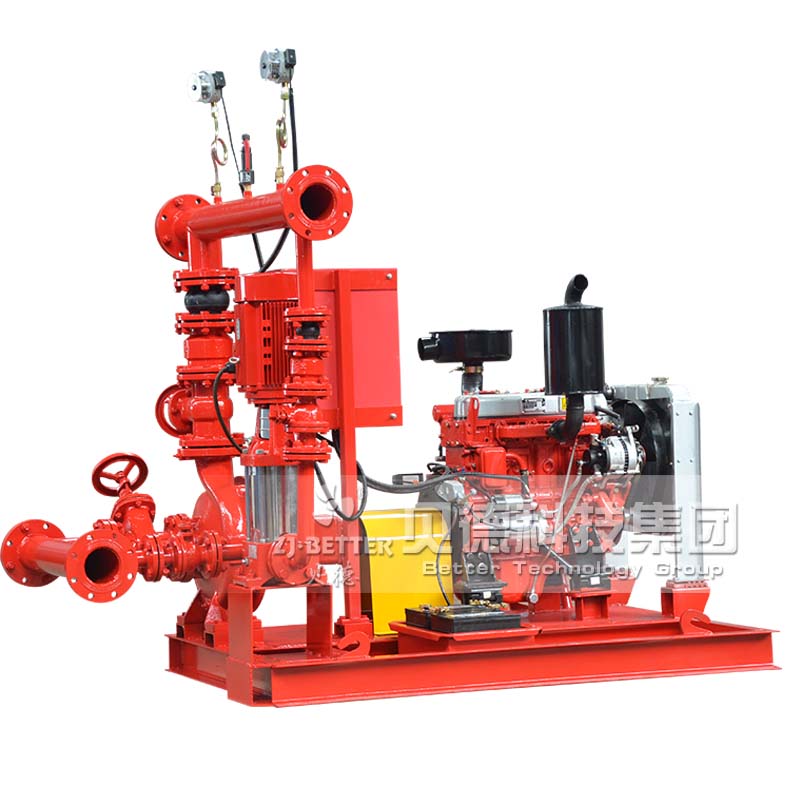

Industrial Grade Diesel Fire Water Pump Unit for Continuous Operation

Industrial-grade diesel fire-fighting water supply units adopt an independent diesel power design, support long-term continuous operation, and have high flow rate, high head and stable output performance. They are suitable for industrial parks, energy facilities and high-risk locations, providing reliable and continuous water supply for fire protection systems.

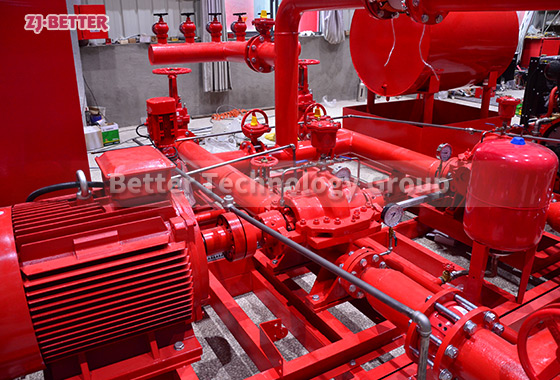

Industrial-grade diesel fire-fighting water supply units, designed as core fire-fighting water supply equipment for high-risk and high-intensity application scenarios, primarily offer the value of continuously and stably providing sufficient water to fire-fighting systems under any complex operating conditions. They are particularly suitable for industrial parks, energy facilities, chemical plants, warehousing and logistics centers, large manufacturing plants, and infrastructure projects where the continuity and reliability of water supply are extremely important. Powered by diesel fuel, these units eliminate reliance on mains power and can quickly start and maintain stable operation even in the event of power outages, voltage instability, or extreme environmental conditions, fundamentally solving the power risks that traditional electric fire-fighting systems may face in emergencies. The entire system is designed to heavy-duty industrial standards, highly integrating the diesel engine, fire pump, cooling system, fuel system, control unit, and piping accessories through a high-strength base. This not only ensures structural stability during operation but also significantly reduces the complexity of on-site installation and commissioning, enabling rapid deployment in actual projects. In terms of performance, this diesel-powered fire-fighting water supply unit achieves stable output of high flow rate and high head at rated speed through scientific matching of power output and pump hydraulic model. This meets the needs of various fire-fighting conditions, including simultaneous water use at multiple points, long-distance water delivery, and high-pressure jetting. Even during the continuous fire-fighting phase after a fire breaks out, it maintains stable pressure, preventing flow rate reduction from affecting fire-fighting efficiency. The diesel power system uses an industrial-grade configuration suitable for continuous operation, possessing excellent torque reserve and load adaptability. Even under high load conditions for extended periods, it maintains stable speed, providing continuous and reliable power support to the fire pump, thus ensuring the continuity of the entire fire-fighting water supply system. To meet the stringent durability requirements of industrial environments, the unit has undergone comprehensive reinforcement in material selection and manufacturing processes. Key pressure-bearing components are made of high-strength materials, capable of withstanding the mechanical stress caused by long-term high-pressure operation. Simultaneously, surface treatment and protective design take into account corrosion resistance, rust prevention, and weather resistance, ensuring the equipment maintains good condition even in humid, high-temperature, dusty, or corrosive environments. The cooling system is also designed for continuous operation. Through an efficient heat dissipation structure and a reasonable airflow or liquid cooling layout, it ensures that the diesel power system remains within a reasonable operating temperature range during long-term operation, avoiding performance degradation or shutdown risks due to overheating. The control system, as the core management unit for unit operation, integrates multiple monitoring and protection functions. It can monitor power status, operating parameters, and system conditions in real time. While ensuring reliable automatic start-up, it also provides operators with clear and intuitive status feedback, promptly issuing alarm signals in case of abnormalities to ensure the safe operation of the equipment and the overall fire protection system. Considering the long-term standby requirements of fire protection systems in industrial sites, this diesel fire-fighting water supply unit fully considered the “long-term standby, immediate start-up” characteristic during the design phase. By optimizing fuel supply, the starting system, and lubrication structure, it ensures that the equipment can still start quickly and reach a stable operating state after long periods of inactivity. The unit also performs excellently in terms of system compatibility, flexibly connecting to different types of fire pipe networks and terminal systems according to actual engineering needs. Whether it’s automatic sprinklers, indoor and outdoor fire hydrants, or dedicated fire water systems for special process areas, efficient matching can be achieved through reasonable configuration. The modular design concept makes maintenance and repair of the equipment more convenient. The rational layout of key components and ample operating space effectively reduce daily maintenance difficulty and downtime costs, enhancing the overall lifecycle value of the equipment. In summary, industrial-grade diesel fire-fighting water supply units, with their independent power advantages, excellent continuous operation capability, stable and reliable hydraulic performance, and high adaptability to complex industrial environments, have become an indispensable and crucial component of fire protection engineering in high-risk locations. They can not only quickly assume core water supply tasks in emergencies but also provide solid and reliable protection for fire protection systems during long-term operation and standby, building a stable and efficient fire-fighting water supply foundation for the safe operation of industrial facilities.