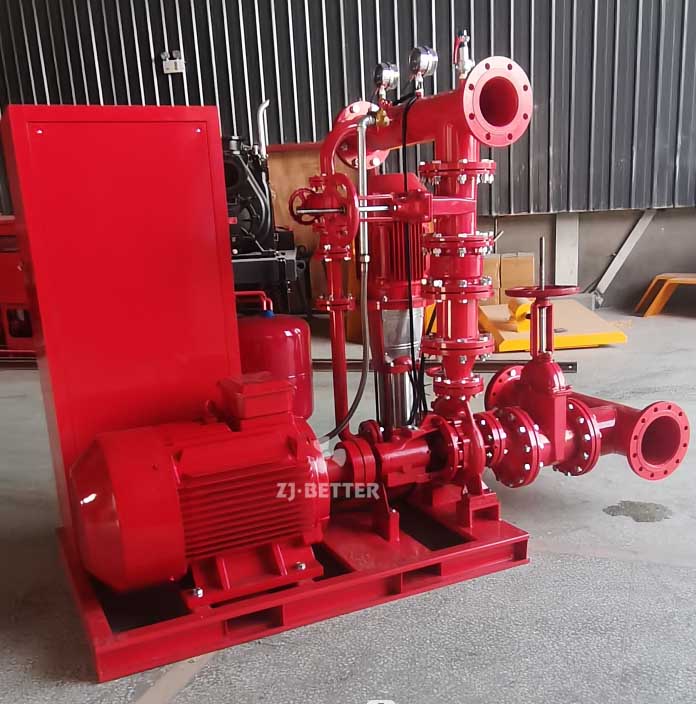

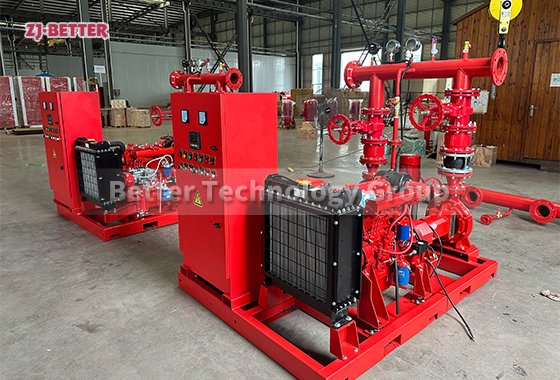

The complete fire pump set is made according to NFPA 20 standard

The fire pump is usually equipped with a local control cabinet. The control cabinet does not have a transfer control switch for automatic and manual conversion, but the automatic control loop leaves start and stop contacts, which are connected to the fire alarm system control module. In addition, according to the relevant regulations, the system using the bus linkage control should also be set in the fire control room with buttons that can directly start and stop the pump. When the fire alarm system receives the signal of the fire hydrant start pump button, the control module automatically starts the fire pump and collects its feedback signal.

The fire pump room is only used for fire fighting equipment and shall not be shared with other machinery industries. This rule applies to all equipment not necessary for the operation of fire pumps, except those related to domestic water distribution. NFPA 20 provides exceptions for domestic water equipment located in fire pump rooms.

There are many factors to consider when designing a fire pump. NFPA 20 contains important requirements that should be strictly followed to ensure fire pumps operate as intended when needed.