Efficient Water Supply Solutions: Application Value of Diesel Fire Pumps in Large Facilities

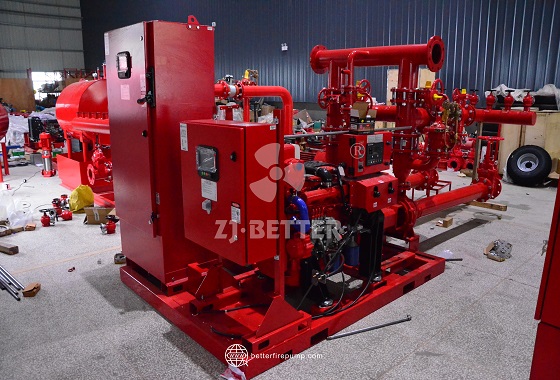

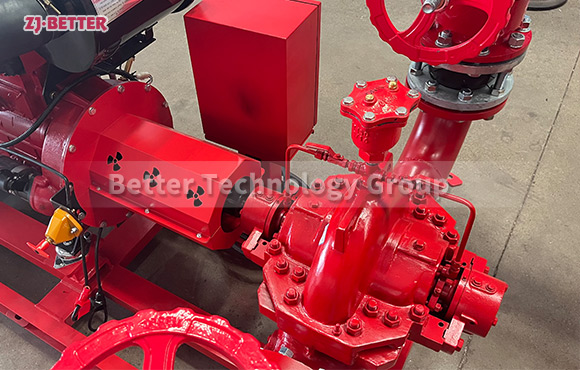

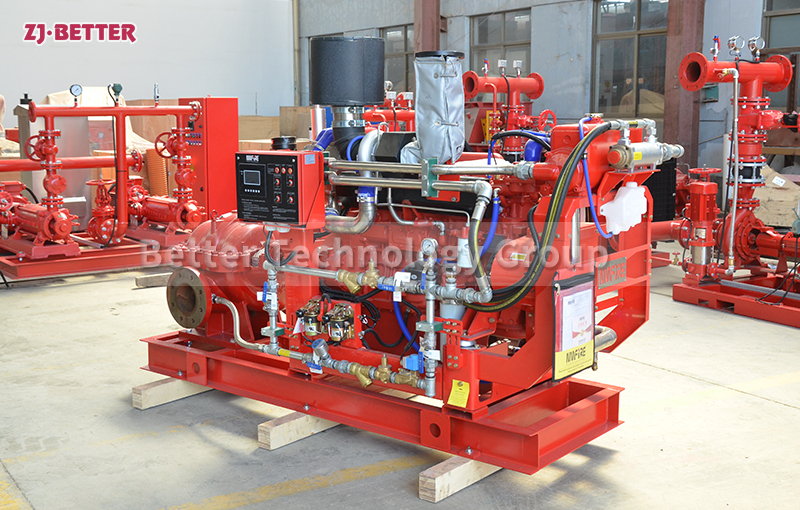

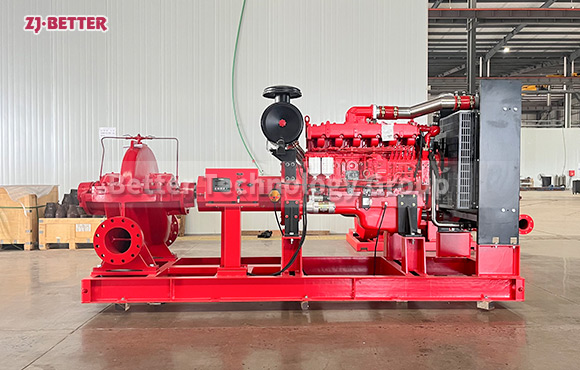

Diesel fire pumps provide efficient water supply for large facilities. They feature independent power, continuous high-pressure output, intelligent control, and strong environmental adaptability. They can operate stably even during power outages or harsh conditions, ensuring the safety and reliability of fire protection systems and meeting the emergency water supply needs of industrial parks, petrochemical plants, warehouses, and high-rise buildings.

Against the backdrop of accelerating urbanization, large-scale facilities such as industrial parks, petrochemical plants, storage bases, commercial complexes, high-rise buildings, and public infrastructure are placing increasingly stringent demands on their firefighting systems. The reliability and efficiency of water supply systems, in particular, directly determine the speed and effectiveness of fire emergency response. Among the numerous firefighting water supply equipment, diesel fire pumps, due to their independent power source, robust water supply capacity, and exceptional durability, have become essential core equipment in large-scale facilities. Compared to electric pumps that rely on municipal power, diesel fire pumps offer independence and stability. They can quickly start and maintain high-pressure water supply even during power outages or fluctuations, ensuring uninterrupted operation of the entire firefighting system at critical moments and buying valuable time for firefighting. Diesel fire pumps are designed with high efficiency and stability in mind. The optimal matching of the engine and pump body ensures that they quickly reach rated speed after startup and deliver sufficient water pressure and flow in a very short time. This characteristic is particularly important for large-scale facilities, given their extensive internal pipe networks, long water supply distances, and high water consumption. Only equipment with strong output and continuous operation can truly meet these firefighting needs. Furthermore, diesel fire pumps offer excellent continuous operation performance, typically capable of operating under high loads for extended periods. The engine system features efficient cooling and lubrication, effectively reducing heat and frictional losses during operation, ensuring the pump’s reliability in emergency situations. This characteristic is particularly crucial in critical locations such as large petrochemical plants, port warehouses, and power plants, where firefighting often requires a continuous water supply. Diesel fire pumps ensure stable water pressure throughout the entire process. Their automated control features also greatly facilitate the management of large-scale facilities. Their intelligent control system enables automatic startup, shutdown, and operational status monitoring. If pipeline pressure drops or a fire alarm is issued, the pump automatically reactivates without manual intervention, significantly improving emergency response efficiency. Furthermore, the system can be equipped with remote monitoring, enabling operators to monitor equipment operating parameters in real time and provide timely warnings and action when an anomaly occurs, reducing the burden of manual inspections and enhancing the safety of the overall fire protection system. Another major advantage of diesel fire pumps is their adaptability, enabling them to operate stably in harsh environments such as high and low temperatures, humidity, and dust. This makes them extremely reliable in complex environments such as metallurgical, mining, and energy bases. Furthermore, the equipment’s design fully considers seismic and corrosion resistance requirements, ensuring a stable structure during long-term operation and preventing performance degradation due to environmental influences. For users, maintenance is relatively simple. The modular design of components facilitates replacement and overhaul, and the diesel engine boasts a long lifespan and extended maintenance intervals, reducing overall operating costs. More importantly, diesel fire pumps are continuously being optimized for energy conservation and environmental protection. Advanced combustion technology and high-efficiency engine designs reduce fuel consumption and exhaust emissions, ensuring strong firefighting system output at critical moments while meeting the green development needs of modern large-scale facilities. In practical applications, diesel fire pumps are often used as the primary water supply device or combined with electric pumps and pressure-stabilizing pumps to meet the needs of various operating scenarios. For example, during low-load conditions, the pressure-stabilizing pump maintains pipe pressure. Once a fire breaks out, the diesel fire pump immediately takes over to provide sufficient water, forming a comprehensive multi-tiered water supply system. This flexible combination allows large-scale facilities to tailor efficient fire water supply solutions to their specific needs, thereby enhancing overall protection. It’s worth noting that diesel fire pumps aren’t limited to responding to fires; they can also play a role in emergency drainage, flood relief, and water supply support for special working conditions, demonstrating their multifunctional application value. Overall, diesel fire pumps, with their multiple advantages, including independent power, efficient water supply, continuous operation, intelligent control, environmental adaptability, and low maintenance costs, have become core equipment in the fire protection systems of large facilities. They not only provide solid support for firefighting in emergency situations, but also help large facilities achieve their long-term safe operation goals through efficient, intelligent, and reliable performance. With the continuous improvement of fire safety standards and the acceleration of intelligent development trends, diesel fire pumps will be widely used in more large facilities, continuing to provide efficient solutions for fire safety and emergency water supply, truly demonstrating their irreplaceable value in large facilities.