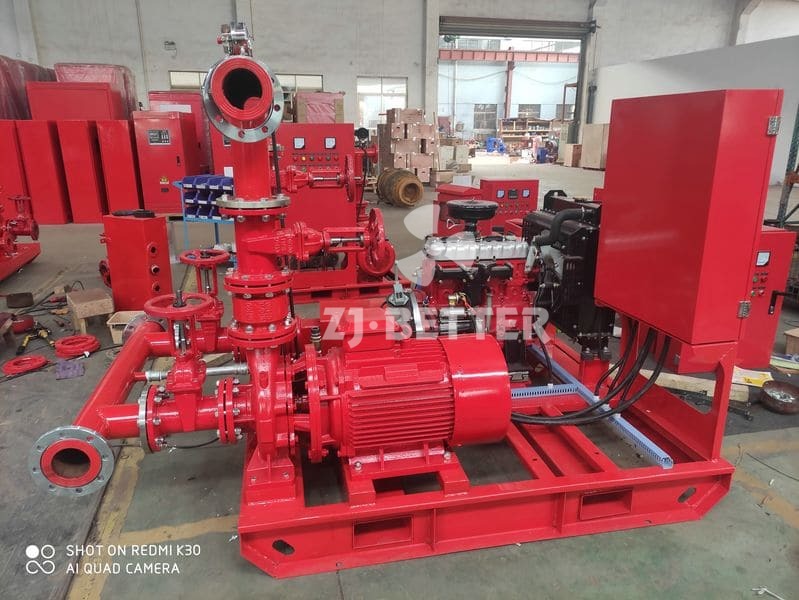

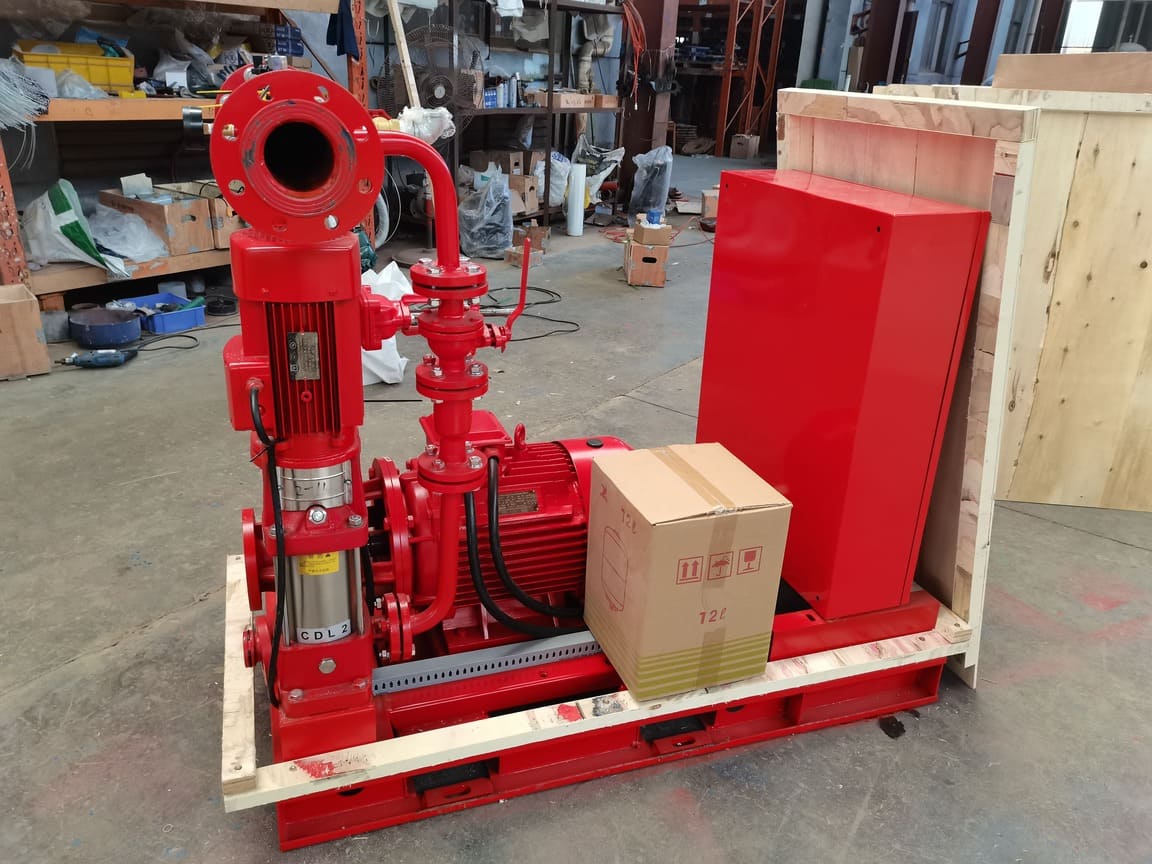

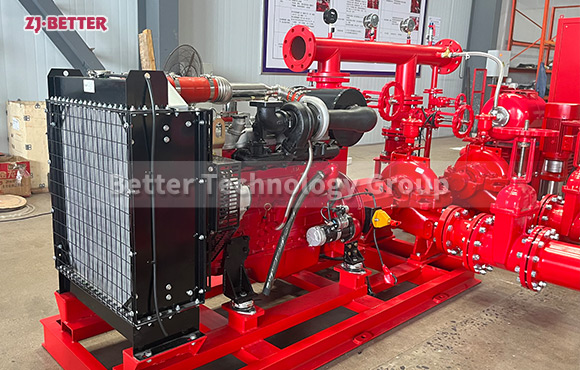

Heavy-Duty Fire Pump Package Designed for Harsh Operating Conditions

Heavy-duty fire pump systems are designed for harsh working conditions, featuring a high-strength structure and a stable power system. They are capable of high flow rate, high head, and continuous operation, making them suitable for fire protection projects in industrial, energy, and high-risk locations, significantly improving the reliability and safety of fire water supply systems.

Heavy-duty fire pump systems are specialized fire-fighting water supply equipment designed for harsh operating conditions. Developed for high-risk, high-load fire applications, their core advantage lies in the synergistic effect of enhanced structural design, stable power configuration, and a highly reliable control system. This ensures the fire pump maintains stable and efficient operation even under complex environments and prolonged emergency operation. These systems are widely used in petrochemical plants, energy and power facilities, large industrial plants, mines, ports, airports, tunnel projects, and other key locations with extremely high requirements for continuous fire protection system operation. These scenarios typically feature high fire risk, complex environmental conditions, and long fire suppression cycles, placing demands on the mechanical strength, operational stability, and durability of fire equipment far exceeding conventional standards. The heavy-duty structural design is one of the most prominent performance characteristics of this fire pump system. Its overall base and support structure are typically made of high-strength steel. Through reasonable stress distribution and reinforcement design, the overall vibration resistance and structural stability of the machine are effectively improved. Even under prolonged full-load operation, the fire pump maintains good mechanical condition, preventing vibration or structural deformation from affecting the equipment’s operational reliability. The fire pump itself has undergone systematic optimization in terms of hydraulic performance, featuring high flow rate, high head, and stable output. It can quickly establish the required system pressure after a fire breaks out, continuously providing sufficient water to indoor fire hydrant systems, automatic sprinkler systems, and outdoor fire hydrant networks. Even under extreme conditions of simultaneous water use at multiple points, it maintains stable pressure, significantly improving overall fire extinguishing efficiency. The power system, as a crucial component of the heavy-duty fire pump assembly, was selected and configured with full consideration of the needs for long-term continuous operation and high-load output. It features ample power reserves and stable output, effectively matching the fire pump’s operational requirements under different conditions and preventing unstable water supply due to insufficient or fluctuating power. The cooling and auxiliary systems are also designed around harsh operating conditions. Through efficient heat dissipation structures and a reasonable system layout, they ensure continuous operation of the equipment in high-temperature, high-humidity, or enclosed environments without performance degradation, thus meeting the stringent reliability requirements of actual fire protection applications. The control system plays a crucial role in ensuring the smooth operation of a complete set of heavy-duty fire pump equipment. It typically integrates automatic and manual control functions, enabling rapid activation based on changes in pipeline pressure or external fire signals. It also supports direct manual intervention in special circumstances, ensuring the fire pump can be quickly deployed in any emergency. The control system possesses comprehensive operational monitoring and protection functions, monitoring key operating parameters in real time. In case of anomalies, it promptly issues alarms and takes corresponding protective measures to prevent continued operation under abnormal conditions, effectively reducing the risk of failure and extending the equipment’s service life. The heavy-duty fire pump equipment also reflects high standards in material selection and manufacturing processes. Key components are made of wear-resistant and corrosion-resistant materials, capable of withstanding alternating periods of long-term operation and sudden high-load operation. Even under long-term use in harsh industrial environments, it maintains stable performance. Integrated design is another significant advantage of this type of equipment. By highly integrating the fire pump, power system, control system, and piping components, it not only reduces the workload of on-site installation and commissioning but also lowers the operational risks arising from the combination of multiple devices, making the project construction cycle more controllable and the system operation more reliable. For project management, heavy-duty fire pump systems not only provide reliable fire water supply during fires but also demonstrate excellent economic efficiency in daily operation and maintenance. By reducing failure rates and maintenance frequency, they effectively lower overall operation and maintenance costs. In summary, heavy-duty fire pump systems, with their robust and durable structural design, stable and efficient hydraulic performance, reliable power and control systems, and high adaptability to harsh operating conditions, offer a safe, reliable, and high-performance solution for modern fire protection engineering. Their continuous water supply capacity and operational stability, demonstrated in critical moments, play an irreplaceable role in protecting personnel and critical assets.