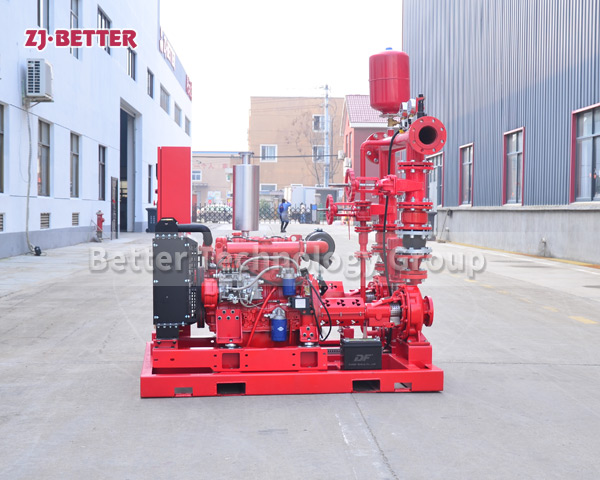

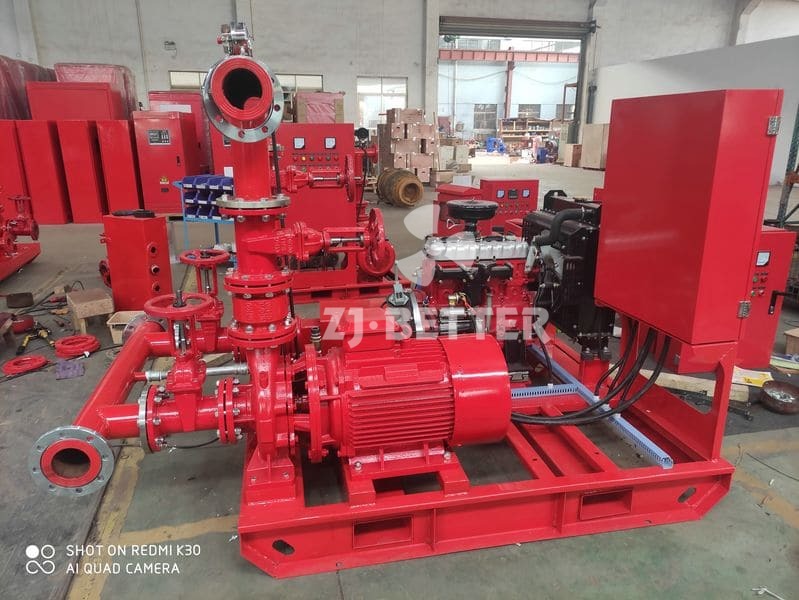

Energy-efficient electric fire pump units, as an indispensable key component of modern fire protection systems, have gradually become a favored water supply equipment in global fire protection engineering due to their highly efficient and energy-saving structural design, stable and reliable performance, and wide applicability in various buildings and industrial facilities. In responding to fire pressure and ensuring a continuous and stable fire water supply, the energy consumption level and performance output of the equipment directly determine the economy, response speed, and sustainability of the entire fire protection system during operation. With the continuous upgrading of fire safety standards across industries, energy-efficient electric fire pump units, with their advantages of intelligent control, optimized hydraulic structure, long-life material application, and low maintenance costs, play an irreplaceable role in building fire protection, industrial fire protection, municipal water supply, and various pump station renovation and upgrade projects. The core advantage of energy-efficient electric fire pump units lies in the perfect combination of their energy-saving performance and efficient water delivery capacity. By using high-efficiency motors, optimized impeller flow channels, precisely matched pump body structures, and overall optimization of fluid dynamics, the unit can reduce energy consumption by 10%–30% compared to traditional fire pump systems under the same flow and pressure conditions. In an era of continuously rising building operating costs, this energy-saving effect not only meets users’ requirements for operational economy but also aligns with the global trend of energy conservation and emission reduction. The high-efficiency motors used in the units typically achieve IE3 or IE4 energy efficiency ratings. The internal copper coils, silicon steel sheets, and insulation system of the motor are optimized, enabling the motor to maintain lower temperature rise and higher energy conversion efficiency during long-term operation, thereby reducing energy loss and extending the overall lifespan of the equipment. In terms of hydraulic design, the pump body adopts a high-quality casting process, resulting in smooth flow channels with no significant resistance areas. The impeller undergoes dynamic balancing to reduce vibration and noise while improving liquid delivery efficiency, allowing the unit to maintain stable and vibration-free operation under high pressure. Regarding continuous output performance, the energy-saving electric fire pump unit, through optimized sealing systems, bearing structures, and cooling methods, can maintain stable pressure output under long-term high load conditions, which is crucial for fire protection systems. In the event of a fire, the fire protection system must provide a continuous high-pressure water supply within a very short time to ensure that sprinkler systems, fire hydrant systems, or foam extinguishing systems can be quickly put into operation. The unit’s high-reliability design ensures that the equipment remains on standby 24/7, 365 days a year, ready to respond to fire commands at any time. Regarding the control system, energy-saving electric fire pump units typically employ intelligent electrical control cabinets, supporting functions such as automatic switching, manual control, remote monitoring, water pressure detection, and fault alarms. The electrical control system can automatically start or stop the fire pump based on pressure changes in the fire hydrant network, ensuring that the system maintains a reasonable pressure during daily operation, avoiding frequent starts due to pressure fluctuations, and preventing energy waste. The intelligent control system also has a soft-start function, effectively reducing the impact of starting current on the power grid and pump body, and lowering the long-term failure rate. To further enhance system stability, the unit is typically equipped with reliable sensors, pressure gauges, check valves, gate valves, safety valves, and other auxiliary components to ensure that the entire operating circuit remains safe and controllable under high pressure. In terms of service life and maintenance, the energy-saving electric fire pump unit is manufactured using high-strength materials that are corrosion-resistant, high-temperature resistant, and wear-resistant, including high-strength cast iron, stainless steel shafts, and wear-resistant mechanical seals with a golden ratio, fundamentally reducing wear and extending the equipment’s service life in harsh environments. The pump body has a compact and reasonable structural design with optimized maintenance access, enabling operators to quickly perform inspections, maintenance, and component replacements, reducing maintenance costs and improving the overall reliability of the equipment in emergency situations. The unit’s lubrication and sealing systems are scientifically designed to effectively reduce leakage risks, ensuring that the components remain well-lubricated, rust-free, and free from jamming even during long periods of standby, guaranteeing reliable start-up. In terms of application scope, the energy-saving electric fire pump unit is suitable for buildings and locations of various sizes, including high-rise buildings, commercial complexes, industrial plants, warehousing and logistics centers, underground garages, municipal factories, public facilities, energy stations, hotels, hospitals, schools, and various locations requiring continuous and stable fire-fighting water supply. Its robust adaptability allows the unit to be customized with multiple parameters such as flow rate and head according to on-site fire protection design requirements, complying with international standards such as NFPA20, GB50974, and EN12845, as well as fire protection codes of various countries and regions. This type of unit is ideal for new fire stations or energy-saving renovation projects of existing fire protection systems, reducing operating costs by improving energy efficiency while enhancing the overall fire protection capabilities and emergency response performance of the building. With the continuous rise in energy costs, these energy-saving benefits are particularly important for large commercial and industrial users, while its powerful performance output ensures reliable fire protection in any emergency. Furthermore, in terms of noise control, the energy-saving electric fire pump unit adopts low-noise motors, precision dynamically balanced impellers, and vibration-damping bases, significantly reducing noise during operation. It is suitable for locations with strict environmental noise requirements, such as hospitals, schools, hotels, and office buildings. The motor does not produce exhaust emissions during operation, making it a green, environmentally friendly, and pollution-free fire water supply solution. In terms of transportation and installation, the units are typically integrated into a base, resulting in a compact structure, small footprint, and ease of hoisting, positioning, and connection. On-site installation only requires connection to power, piping, and control lines to put them into operation, significantly saving construction time. Standardized design ensures rapid adaptation to different projects, improving project progress and construction efficiency. Diverse configurations, such as single-pump, dual-pump, and multi-pump combinations, can be flexibly configured according to project needs to meet water supply requirements in various scenarios. In summary, energy-efficient electric fire pump units, with their energy-saving efficiency, optimized structure, intelligent control, reliability, stability, simple maintenance, and wide applicability, have become the preferred equipment for efficient water supply in modern fire protection systems. They significantly reduce long-term operating costs while ensuring fire safety, bringing higher safety guarantees and usage value to various buildings and industrial facilities. In the future fire protection market, with the continued deepening of energy conservation and environmental protection concepts and the continuous improvement of fire protection standards, energy-efficient electric fire pump units will continue to play an important role in global fire protection system construction, providing strong support for personnel safety and property protection, thanks to their higher energy efficiency, more intelligent control technology, and more reliable operating performance.