Best Equipment for Field Construction and Temporary Fire Systems: Full Review of Mobile Fire Pumps

A comprehensive evaluation of mobile fire pumps provides an in-depth analysis of their core advantages in field construction and temporary fire protection systems, including high mobility, autonomous power, high head and large flow output, intelligent control, and adaptability to multiple scenarios, providing efficient and reliable emergency water supply solutions for engineering projects, mining areas, oil fields, and temporary fire protection needs.

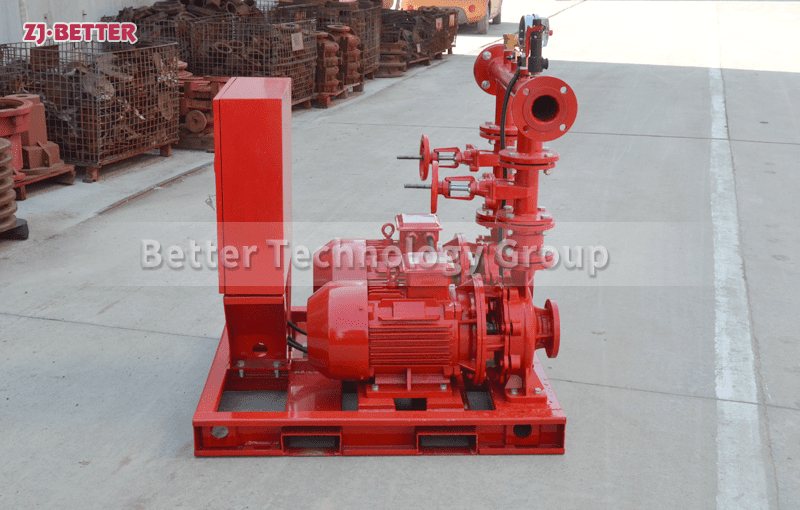

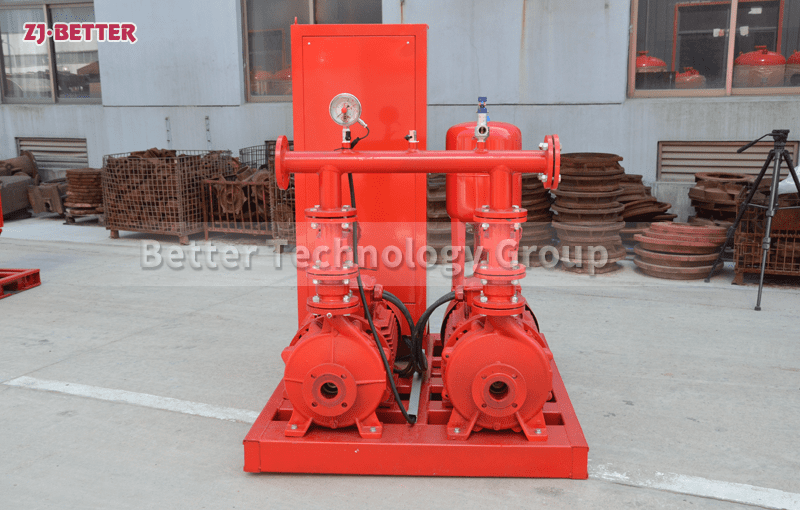

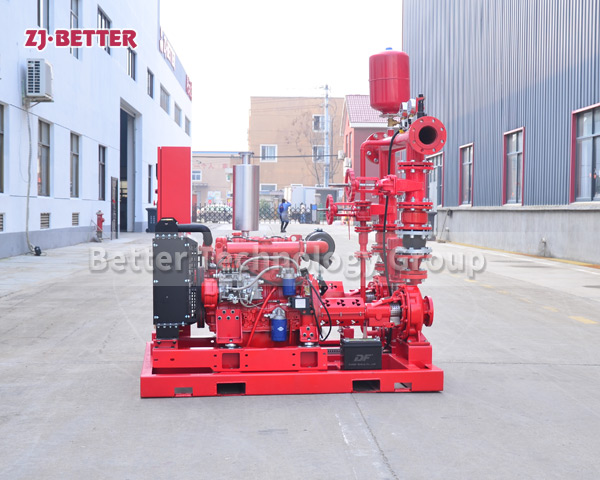

Mobile fire pumps, as indispensable core firefighting equipment in field construction, remote area engineering projects, and various temporary fire protection systems, occupy an extremely important position in modern emergency fire protection systems due to their flexible deployment, independent power, adaptability to complex environments, and efficient water supply capabilities. As construction in the building, municipal, energy, mining, chemical, agricultural, and infrastructure sectors expands to farther distances and more complex working conditions, traditional stationary fire pumps can no longer meet the demands for rapid deployment and mobile operations. Mobile fire pumps are a comprehensive device that emerged to solve these problems. Through a trailer-mounted chassis, independent power system, stable pump body structure, and a quickly connectable piping system, they can play a more efficient and vital role in scenarios with limited power supply, frequently changing construction environments, and the need to establish pump houses in a short time. The widespread use of mobile fire pumps in field construction and temporary fire protection systems stems primarily from their high mobility and transportability. Equipped with a robust mobile chassis, they can be towed by trailers, pickup trucks, or small transport vehicles. No complex installation or securing process is required; once on-site, only simple piping connections are needed for immediate deployment. This is extremely valuable for emergency construction projects, temporary water supply scheduling, and cross-regional firefighting support. While other firefighting equipment is still being transported or deployed, mobile fire pumps can be put into operation first, buying valuable time to control the fire, stabilize on-site water pressure, and ensure construction safety. Furthermore, their compact structure and small footprint allow for flexible movement on narrow roads, mountain slopes, rural areas, or unpaved surfaces. They maintain good mobility even on unpaved surfaces such as mud and gravel roads, enabling them to reach work sites smoothly in various complex outdoor environments. Secondly, one of the biggest advantages of mobile fire pumps is their self-sufficient power system, which requires no external power support. Equipped with a high-power diesel engine, the unit can maintain continuous, stable, and high-power output in power outages, areas without electricity, and remote construction sites. Whether providing continuous water supply to a single sprinkler system or providing high-pressure replenishment to multiple fire hoses, it can maintain high-efficiency operation. Compared to electric fire pumps that rely on the power grid, mobile fire pumps operate completely independently, significantly improving their ability to respond to emergencies. They are particularly suitable for scenarios without a stable power source, such as mining construction, oilfield drilling, highway construction sections, and temporary storage areas. Their power systems also feature high durability, low fuel consumption, and simple maintenance, making them more reliable for long-term field use. As a crucial component of temporary fire protection systems, mobile fire pumps utilize a high-performance centrifugal structure, providing powerful head and flow rate. Different models can be matched to different flow ranges according to the application scenario, meeting the needs of large-scale engineering fire water supply, external water source extraction, and long-distance pipeline water transmission. In situations where the water source is far away, the terrain has a large elevation difference, or a continuous high-pressure water supply is required, mobile fire pumps can maintain stable output through optimized impeller structure and pump body channel design, making them outstanding in long-distance water transmission and temporary fire water supply for high-rise buildings. Furthermore, they have rapid start-up capabilities, quickly resuming full-load operation upon receiving an order, making them extremely valuable for responding to sudden fires, emergency drainage, and water source interruptions. Its cooling, lubrication, and fuel systems are all designed to high reliability standards, ensuring that overheating, wear, or power attenuation are unlikely during long-term continuous operation. This is one of the key reasons why it is highly favored in the emergency firefighting industry. In field construction environments, mobile fire pumps have an extremely wide range of applications, not only in traditional firefighting scenarios but also supporting various engineering needs. For example, in road construction or bridge engineering, they can be used to provide temporary water supply to support concrete mixing, dust suppression, or equipment cooling; in farmland irrigation construction, they can be used for canal replenishment, field pumping, and water source scheduling; in mining areas or petrochemical sites, they can be used to transport process water, provide equipment cooling water, or handle cleaning and flushing operations after sudden leaks. In these scenarios, their flexible mobility and immediate usability significantly improve engineering efficiency. For mobile fire pumps, which are the core equipment of temporary firefighting systems, their control system is equally crucial. The equipment is typically equipped with an intelligent control panel that can monitor key parameters such as water pressure, flow rate, speed, oil volume, and temperature in real time, enabling operators to accurately grasp the equipment’s operating status in complex environments. Some systems are also equipped with automatic protection functions, such as automatic load reduction for excessively high water temperature, automatic shutdown for insufficient oil pressure, and automatic alarm for pump malfunctions, ensuring the reliability and safety of the equipment during long-term, high-intensity operation in the field. For temporary fire protection systems requiring multi-device coordination, multi-pump linkage operation can be achieved through interconnected control to ensure the water pressure stability of the entire system. Mobile fire pumps also perform excellently in terms of structural strength and durability. Their pump bodies utilize heavy-duty welded bases, reinforced structural components, anti-corrosion coatings, and impact-resistant protection, enabling them to withstand harsh conditions such as field transportation, mechanical collisions, rain erosion, and temperature fluctuations. Simultaneously, the trailer structure is equipped with a buffer and shock absorption system to ensure that the pump body and power system are not damaged during transportation on rough roads. This weather resistance and impact resistance allow them to adapt to the challenges of the outdoor environment for extended periods. The equipment also boasts greater compatibility, connecting to various interfaces such as hoses, fire hoses, temporary water supply lines, and high-pressure water tankers, allowing for rapid integration into different types of fire protection systems. Whether it’s a temporary water storage tank, well, river, lake, or underground fire protection network, it can serve as a water source and provide stable power. It is compatible with international standard interfaces, facilitating cross-industry collaboration and joint emergency use by multiple units. In temporary fire protection systems, mobile fire pumps can be combined with sprinkler systems, dry powder extinguishing devices, foam mixing equipment, etc., to form a comprehensive fire protection solution. For large construction sites, temporary warehouses, power facility maintenance areas, logistics yards, and field platforms, it not only meets the temporary requirements of fire regulations but also significantly reduces construction costs caused by the lack of fixed pump rooms. Since no foundation construction is required, its transportation, deployment, dismantling, and relocation are very rapid, significantly improving flexibility. In summary, as an irreplaceable key piece of equipment in field construction and temporary fire protection systems, mobile fire pumps combine numerous advantages such as convenient mobility, self-powered operation, efficient water supply, long-distance water delivery, reliable structure, intelligent control, and strong adaptability, providing stable and reliable fire protection power support in various complex environments and temporary needs. Whether facing emergency fires, temporary water use, cross-regional support, or long-term engineering construction, it demonstrates superior performance and effectively enhances on-site safety capabilities. With the increasing demand for flexible fire-fighting equipment in modern engineering projects, mobile fire pumps will continue to play an increasingly important role and are a highly efficient fire-fighting equipment that is worth long-term configuration for various construction units, emergency departments, and project operators.