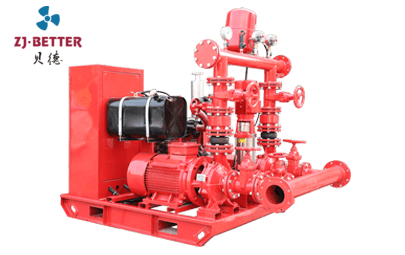

Indoor Pump Room Electric Fire Pump Set for Stable and Quiet Operation

The indoor computer room-specific electric fire pump unit features low noise, high stability, and continuous pressure supply performance, providing reliable, safe, and efficient indoor fire water supply for various types of buildings.

The indoor computer room-specific electric fire pump unit is a high-performance water supply device meticulously designed for the fire safety needs of modern buildings. Driven by a motor, it provides stable, efficient, and continuous fire-fighting water supply, making it particularly suitable for applications with strict requirements for noise control, operational stability, and long-term pressure supply, such as office buildings, hospitals, hotels, shopping malls, warehouses, underground spaces, and industrial facilities. Through standardized design and modular structure, this type of equipment better adapts to the installation conditions of indoor computer rooms, achieving a small footprint, simple layout, and convenient maintenance. Simultaneously, relying on high-efficiency motors, optimized pump structure, intelligent control systems, and user-friendly interfaces, it ensures that the entire system maintains stable, reliable, and low-noise operation during daily inspections, emergency starts, and continuous water supply. Under increasingly stringent fire safety regulations and building safety standards, the indoor computer room-specific electric fire pump unit has become the preferred solution for many engineering projects. The core advantage of this unit is primarily reflected in its operational stability. As a power source, the electric motor features rapid response, smooth start-up and shutdown, and low vibration. Its precise matching design with the fire pump head allows the entire unit to reach the set pressure instantly upon startup and maintain minimal pressure fluctuations during continuous operation. This not only improves the water supply quality of the fire protection system but also reduces pipeline impact caused by pressure changes, thus extending the overall system lifespan. Simultaneously, its compact base and pump body layout facilitate indoor installation, conforming to various machine room dimensions. The inlet/outlet direction and control cabinet location can be customized according to user needs, making installation more flexible. Secondly, the unit offers significant advantages in noise control. The electric motor itself employs a low-vibration structure, resulting in significantly lower noise levels during operation compared to traditional power units. Combined with an optimized pump body hydraulic structure and vibration-damping base, it maintains a low noise level in 24-hour environments, making it ideal for noise-sensitive indoor locations such as hospital machine rooms, commercial complex equipment floors, and office building basements. Furthermore, some units can be equipped with silencers and flexible connection accessories according to project requirements, further enhancing noise control and meeting higher acoustic environment standards. Continuous pressure supply capability is another key advantage of indoor computer room-specific electric fire pump units. The unit utilizes a high-efficiency closed-loop motor and an optimized pump body design, featuring high output pressure, sufficient flow, and stable head. During a fire, the fire pump needs to maintain a stable water supply for an extended period. Through continuous heat dissipation design, thickened base support, and high-strength materials, the unit is capable of long-term load operation, maintaining stable performance even in high-temperature and high-humidity environments, without performance degradation due to overheating or vibration. Its durability has undergone multiple rounds of testing to ensure a reliable water supply to the pipeline network in critical moments. The control system is the intelligent core of the entire unit. Indoor computer room-specific electric fire pump systems are typically equipped with a fully functional electrical control cabinet, supporting automatic, manual, and remote multi-mode control. Automatic mode monitors pipeline pressure in real time via pressure sensors, automatically starting the fire pump when the pressure drops to the set value to ensure uninterrupted water supply. Manual mode meets the direct control needs during unit commissioning and maintenance. Remote mode allows connection to the building fire control center for unified control and centralized monitoring. The control system interface is typically designed to be clear and concise, displaying real-time operating parameters, including key data such as current, voltage, frequency, pressure, and running time, allowing managers to quickly grasp the unit’s status. Simultaneously, the unit possesses self-diagnostic and self-protection functions, such as overload protection, phase loss protection, short circuit protection, over-temperature protection, and low-pressure alarms, ensuring timely alarms or automatic shutdowns in case of abnormal conditions, thereby preventing equipment damage or even safety risks. To adapt to different engineering needs, indoor computer room-specific electric fire pump units can often be combined with components such as pressure-stabilizing pumps, small-flow pumps, and pressure tanks to form complete water supply systems, maintaining the fire pipeline pressure within a reasonable range, thereby reducing frequent main pump starts and extending system lifespan. The unit typically uses corrosion-resistant materials and is equipped with a reinforced protective coating, ensuring structural stability and safety even in high-humidity computer room environments. Furthermore, its connecting components undergo anti-corrosion and pressure-resistant treatment, maintaining sealing and strength over long periods and adapting to various pipeline pressure changes. Another significant advantage of this unit is its remarkable energy-saving effect. Utilizing a high-efficiency, energy-saving motor and optimized hydraulic design, the unit achieves lower energy consumption while maintaining the same performance parameters, aligning with current green building trends and energy conservation and emission reduction requirements. Its pressure stabilization system also reduces the main pump’s operating frequency in non-fire conditions, further saving energy and maintenance costs. The unit’s simple and convenient installation and maintenance are also key factors favored by engineering teams. The unit typically employs a welded base structure, with all equipment pre-installed on the base, including the fire pump, motor, electrical control cabinet, valves, pressure gauges, etc. Users only need to connect the inlet and outlet water pipes and power supply in the machine room to put it into use, minimizing installation difficulty. The unit’s maintenance area is rationally designed, with easy access to the pump body, couplings, motor, and piping, facilitating routine inspections and maintenance by engineering personnel. Overall, the indoor machine room-specific electric fire pump unit is a professional fire-fighting water supply equipment that integrates multiple advantages such as stable operation, low noise design, continuous pressure supply capacity, intelligent control, energy efficiency, and convenient installation and maintenance. It not only meets the stringent fire safety standards of modern buildings, but also ensures a continuous and stable fire water supply during emergency fires through its high efficiency and reliable operation. It has irreplaceable application value for various large building complexes, high-rise buildings, industrial parks, underground facilities, and other projects. As modern buildings increasingly demand safety, energy conservation, and intelligence, this type of electric fire pump unit will continue to be one of the most mainstream and ideal core power equipment in fire protection systems, playing a crucial role in safeguarding life and property.