Advantages and Performance Analysis of Dual Power Fire Pump Sets

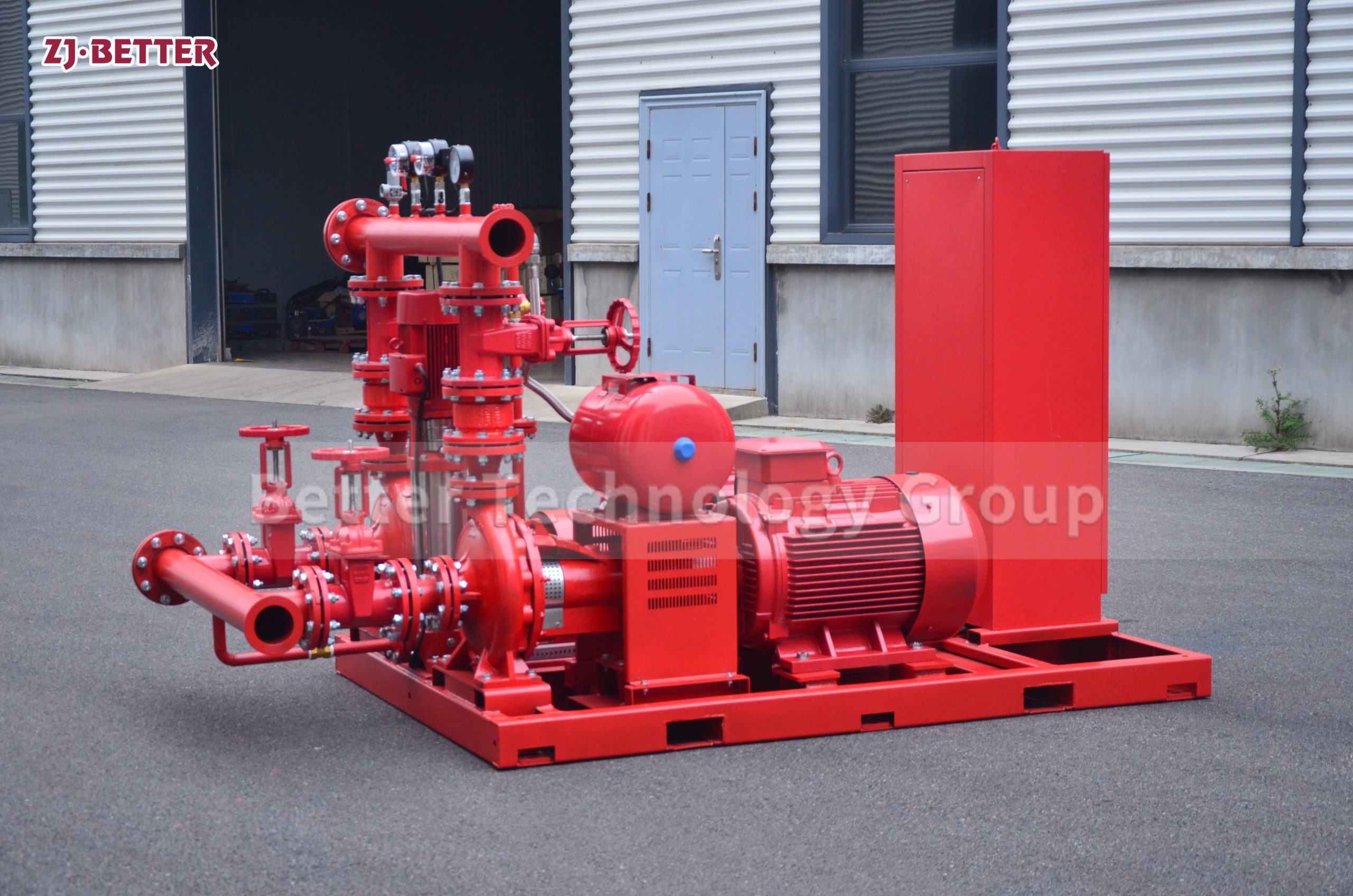

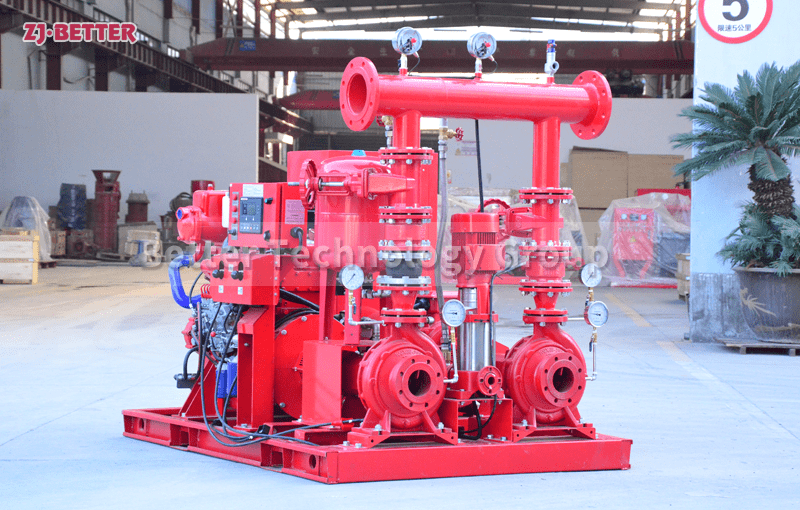

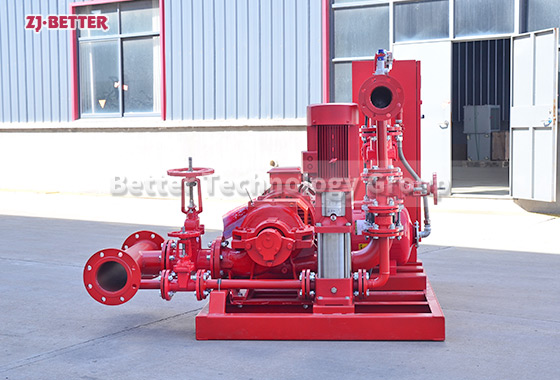

High-efficiency dual power fire pump set with electric and diesel drive ensures continuous water supply during power outages or emergencies. Reliable, energy-saving, and durable, ideal for high-rise buildings, industrial parks, petrochemical, and power facilities to enhance fire safety.

Dual-power fire pump units, essential components of modern fire protection systems in buildings and industrial facilities, are designed to meet the demands of firefighting in diverse and complex environments, ensuring a continuous and stable supply of water in emergency situations like fires. Compared to traditional single-power fire pumps, dual-power pump units combine both a diesel engine and an electric motor, offering significant advantages in energy redundancy, safety, reliability, and applicability. Their overall performance and value have been widely adopted and proven. First, from a power system perspective, the most significant feature of dual-power fire pump units is their dual-power configuration. Under normal operation, the electric motor serves as the primary power source, operating on mains power. This provides smooth operation, low noise, and low energy consumption, meeting the daily standby requirements of the fire protection network. In the event of a power outage, blackout, or power system failure, the diesel engine quickly takes over the entire water supply, ensuring efficient operation of the fire protection system even in the event of a power outage. This dual-power configuration effectively mitigates the risks associated with a single power source and significantly enhances the reliability and emergency response capabilities of the fire protection system. Secondly, in terms of performance and stability, the dual-power fire pump unit utilizes advanced design concepts and manufacturing processes, resulting in a compact structure and high operational efficiency. It can quickly reach rated flow and head requirements, ensuring sufficient water pressure and continuous water supply during firefighting. Whether in high-rise buildings, underground spaces, or large industrial parks, this pump unit ensures continuous and stable water supply. Furthermore, its accompanying automatic control system monitors the unit’s operating status in real time, automatically switching drive modes and providing alarms, further enhancing its intelligence and safety. Regarding energy conservation and environmental protection, the dual-power fire pump unit’s design fully considers energy efficiency optimization. The electric motor offers low energy consumption and high efficiency during daily operation, reducing energy consumption and operating costs. The diesel engine, which kicks in in emergencies, avoids long-term idling and energy waste. Furthermore, continuous advancements in modern diesel engine technology enable more complete combustion and lower emissions, reducing environmental impact and meeting green energy conservation requirements. In terms of durability and reliability, the dual-power fire pump unit’s components are constructed of high-strength materials and treated with corrosion-resistant treatments, ensuring stable operation in harsh environments such as high temperature, high humidity, and dust, extending its service life. The pump body is typically constructed of high-quality cast iron or stainless steel, offering wear and corrosion resistance, ensuring long-term operation without leakage or performance degradation. The power supply is extensively tested and verified, ensuring stability and reliability even under long-term, high-load conditions, while also reducing maintenance costs. Another major advantage of dual-power fire pump sets is their wide range of applications. They are suitable not only for conventional locations such as high-rise buildings, residential communities, commercial complexes, and warehouses and logistics centers, but also for specialized industries with extremely stringent fire water supply requirements, such as the petrochemical industry, metallurgy, power generation, docks, and airports. These locations are often subject to the risk of unstable power supply or power outages. Therefore, the dual-power fire pump set provides strong protection, ensuring that the fire protection system can function at its maximum capacity under any circumstances. Furthermore, the dual-power fire pump set is highly customizable. Based on project requirements, various power, flow, and head combinations can be flexibly selected, along with customizable control cabinets, valves, and piping systems to optimally match the site’s environment. This customization not only enhances applicability but also reduces unnecessary waste during construction and subsequent operation. Convenient operation and maintenance are also a key feature of this equipment. Modern dual-power fire pump systems are generally equipped with intelligent control systems, allowing users to control one-touch start and stop, automatic switching, and fault diagnosis through a human-machine interface, simplifying operation. Furthermore, the pump systems feature a rational structure, with key components compactly arranged for easy access. Maintenance eliminates the need for extensive disassembly and assembly, saving both time and labor costs. For management, this not only improves operational efficiency but also significantly reduces maintenance costs over time. From an economic perspective, while dual-power fire pump systems may require a slightly higher initial investment than single-power pump systems, their low failure rate, high reliability, low energy consumption, and emergency response capabilities over the long term significantly reduce operating costs and fire risk. In other words, dual-power fire pump systems are an extremely cost-effective investment, ensuring a stable and efficient fire protection system with minimal risk. Regarding technological developments, dual-power fire pump systems are increasingly integrating advanced technologies such as the Internet of Things and big data to enable remote monitoring and intelligent management. Sensors collect real-time operating data, allowing managers to monitor equipment status on a remote monitoring platform, providing timely maintenance alerts and troubleshooting, further enhancing the efficiency and effectiveness of management. In summary, the dual-power fire pump unit is a modern firefighting device that integrates high efficiency, safety, reliability, energy conservation, and intelligence. Its dual drive mode, powered by both an electric motor and a diesel engine, ensures continuous water supply in a variety of complex situations. Its advantages are reflected not only in its performance but also in its comprehensive improvement in application value and economic benefits. Whether used in building firefighting or industrial firefighting, it provides the most powerful support, becoming a solid backing for protecting life and property.