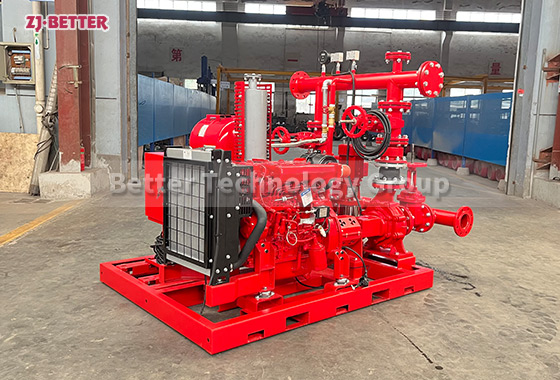

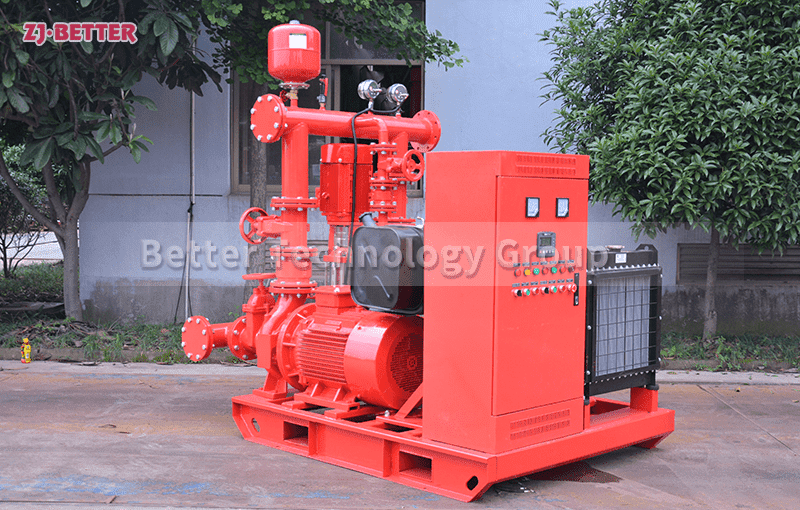

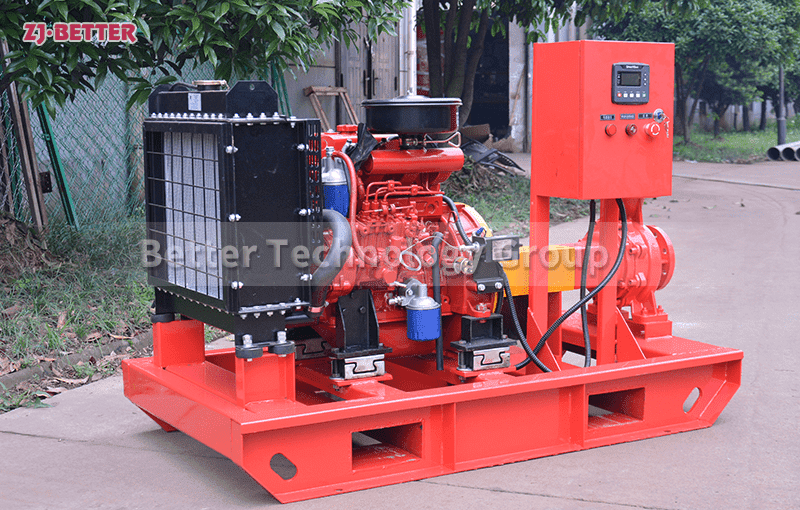

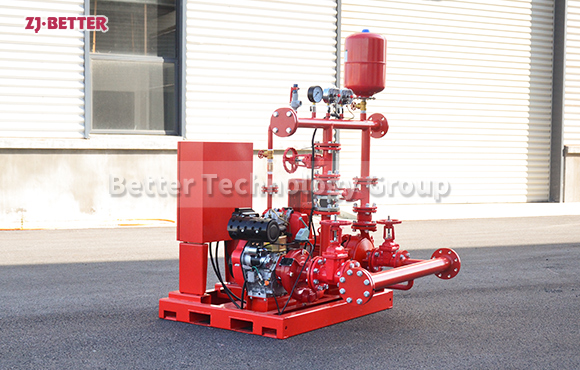

Diesel Fire Water Pump for Factories and Warehouses with Instant Emergency Start

The diesel-powered fire pump is designed specifically for factories and warehouses. It utilizes an independent diesel engine, allowing for automatic and rapid startup in the event of a power outage, providing a stable, high-flow water supply for firefighting. Its robust and durable structure makes it suitable for all-weather emergency fire suppression systems.

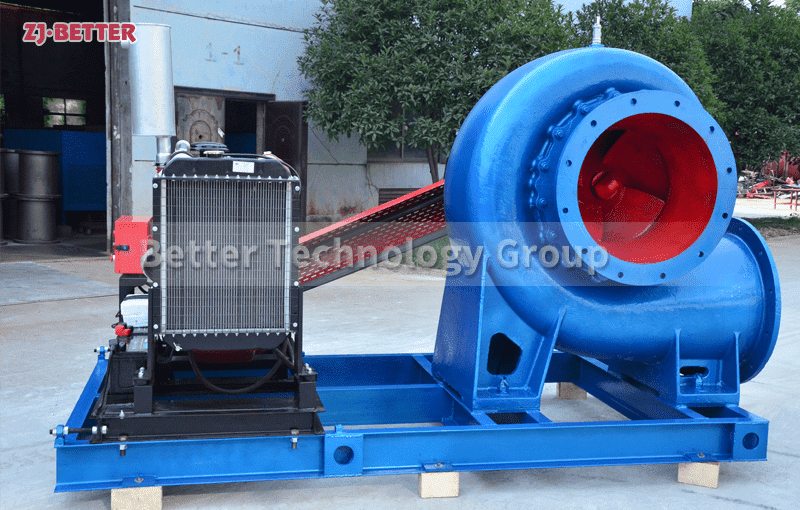

Diesel-powered fire pumps for factories and warehouses, designed for all-weather emergency startup, are a core component of modern industrial and logistics fire protection systems. Their value is particularly evident in high-risk environments with unstable power supply or sudden power outages. This type of diesel fire pump uses an independent diesel engine as its power source, completely independent of the external power grid. Even in the event of a main power failure, damaged distribution system, or lack of power during the initial stages of a fire, it can quickly self-start and operate continuously and stably, ensuring reliable water supply to the fire protection network at critical moments. The overall structure typically consists of a diesel power system, fire centrifugal pump body, coupling, cooling system, fuel system, control system, and a high-strength integrated base. Each functional module is systematically matched and designed to maintain excellent stability and durability even under high load and long-term operation. The diesel power system uses an industrial-grade engine with sufficient torque output, strong fuel adaptability, and a high starting success rate. Even in low-temperature, humid, or dusty factory and warehouse environments, it ensures reliable ignition and continuous operation. The engine is equipped with high-efficiency air and fuel filters to effectively reduce wear on internal components and extend the service life of the entire unit. The fire pump section typically uses a high-efficiency centrifugal pump structure with an optimized hydraulic model. While meeting fire safety regulations, it achieves high flow rate and stable head output, quickly providing sufficient water to fire hydrant systems, sprinkler systems, or other fire protection terminals, ensuring effective control in the initial stages of a fire. The pump body is usually made of high-strength cast iron or alloy materials, possessing good pressure resistance and corrosion resistance, suitable for long-term static standby and frequent switching between standby and operational modes. The overall structure emphasizes compactness and rationality. The engine and pump body are directly or flexibly connected via a high-precision coupling, reducing transmission losses and vibration. This also facilitates later inspection and maintenance. The reinforced base effectively absorbs mechanical vibrations generated during operation, ensuring stable operation on concrete floors or steel structures, making it particularly suitable for diverse installation environments such as factory equipment rooms and warehouse fire pump rooms. In terms of control and starting performance, this diesel fire pump is equipped with a dedicated automatic control system, enabling multiple modes such as manual start, automatic start, and remote signal linkage start. When the fire pipeline pressure drops abnormally or a fire system start signal is received, the equipment can start and reach its rated operating condition in a very short time, significantly reducing response time. The control system typically features multiple operating status monitoring functions, displaying key parameters such as rotational speed, oil pressure, water temperature, and battery voltage in real time, helping managers to promptly understand the equipment status and improve the overall reliability of the fire protection system. Considering the characteristics of continuous production and concentrated storage of goods in factories and warehouses, this diesel fire pump is designed to emphasize long-term continuous operation capabilities. The cooling system adopts a high-efficiency water-cooled or air-cooled plus composite heat dissipation structure, ensuring that the engine and pump body maintain safe operating temperatures even under high ambient temperatures or prolonged full-load operation, avoiding performance degradation or shutdown risks due to overheating. The fuel system capacity is designed to fully consider emergency situations, supporting the equipment’s continuous operation for an extended period without external refueling, thus gaining valuable time for firefighting. This is particularly important in large warehouses, logistics parks, and industrial areas far from urban centers. From a safety and reliability perspective, this type of diesel fire pump is usually equipped with multiple protection mechanisms, including overspeed protection, low oil pressure alarm, and high water temperature alarm functions, ensuring equipment safety while preventing accidental shutdowns that could affect fire water supply. Its design philosophy revolves around the core fire protection requirement of “must start at critical moments and must provide continuous water supply after starting.” Compared to systems that rely solely on electric fire pumps, the diesel fire pump, as an independent backup power source, significantly enhances the safety redundancy of the entire fire protection system, effectively coping with complex emergencies such as power system failures and fire-induced line damage. It is an indispensable piece of equipment in factory and warehouse fire protection design. In practical applications, this equipment is widely used in manufacturing plants, raw material warehouses, finished product storage centers, logistics distribution bases, and other places with extremely high requirements for continuous fire water supply. It not only meets the fire protection regulations for backup power fire pump configurations but also demonstrates significant advantages in long-term operating costs, maintenance convenience, and reliability. Overall, diesel-powered fire pumps suitable for factories and warehouses provide robust protection for industrial and warehousing fire protection systems, thanks to their all-weather emergency start capability, stable and reliable power output, efficient water supply performance, and comprehensive control and protection design. They are a critical fire safety equipment choice for ensuring personnel safety, property protection, and production continuity.