What is the Importance of Intelligent Control Systems in Electric Fire Pumps?

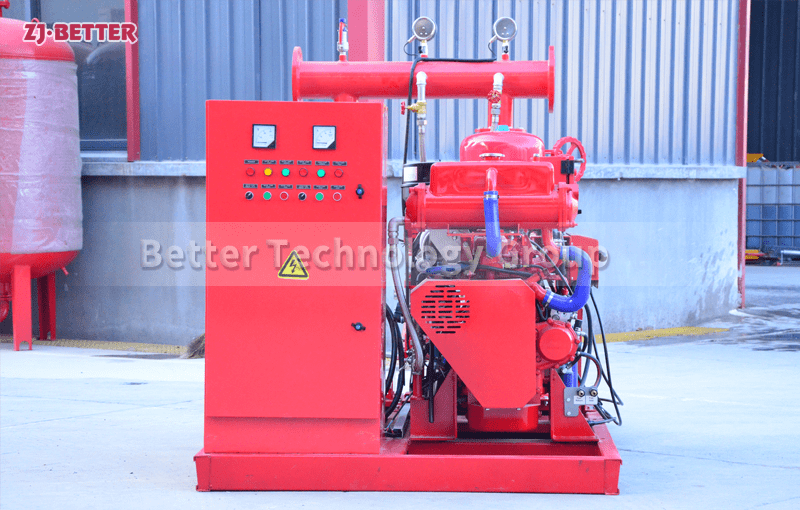

The intelligent control system plays a critical role in modern electric fire pumps. By integrating advanced sensors and control panels, the electric fire pump can continuously monitor key parameters such as water flow, pressure, and temperature, automatically adjusting the pump’s operation to ensure stable water pressure delivery. In emergency situations, the intelligent control system responds quickly, ensuring the pump starts promptly and provides the required water flow and pressure, facilitating smooth firefighting operations.

In addition to improving response time, the intelligent control system offers fault alerts and remote monitoring capabilities, reducing the need for manual intervention and enhancing the reliability and safety of the equipment. The system’s automated design effectively reduces maintenance costs and extends the pump’s service life, making it an indispensable component in modern fire protection systems.

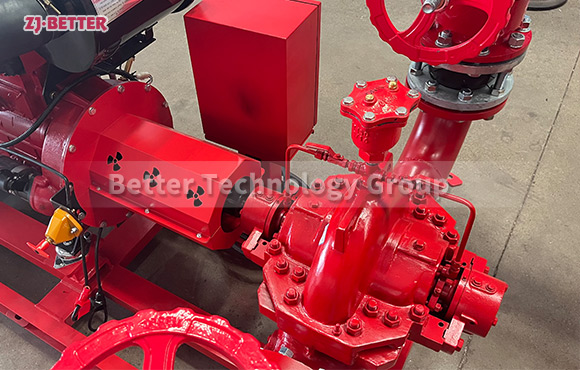

As a leading manufacturer of fire pump systems, we focus on delivering efficient and reliable fire protection solutions, committed to safeguarding buildings and industrial facilities worldwide. Our product range includes electric fire pumps, diesel engine fire pumps, and automated control systems, widely used in high-rise buildings, industrial parks, storage facilities, and municipal projects.

We continuously innovate by incorporating intelligent control technology to optimize pump system efficiency, reduce energy consumption, and enhance safety. Each unit undergoes rigorous testing before leaving the factory, ensuring stable and high-performance operation even in high-pressure and high-temperature environments. Additionally, our fire pumps feature quick start-up and smart monitoring functions, ensuring immediate response and effective water supply for firefighting during emergencies.

We provide not only high-quality equipment but also comprehensive after-sales service and technical support, helping customers achieve optimal fire protection performance in various applications.