Performance Advantages of Direct-Coupled Diesel Fire Pumps in Mobile Firefighting Systems

High-reliability diesel direct-coupled fire pumps designed for mobile firefighting systems, offering stable flow, strong power output, compact structure, fast deployment, and dependable performance in emergency, remote, and off-grid fire protection applications.

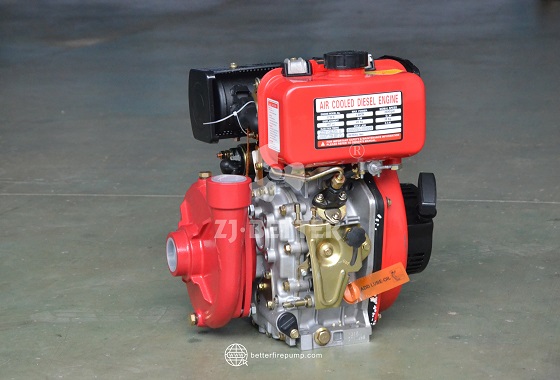

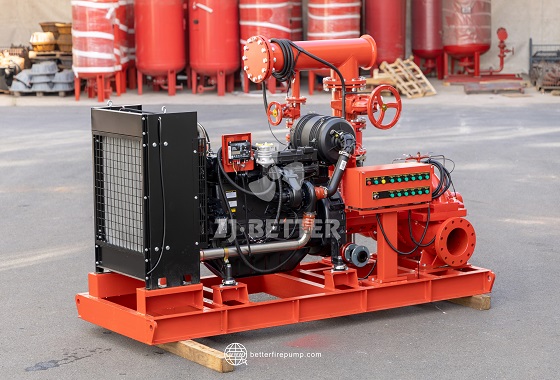

The performance advantages of high-reliability diesel engine direct-drive fire pumps in mobile fire protection systems are reflected in their overall structure and operating logic, specifically designed for complex environments and emergency situations. These fire pumps typically employ a direct connection between the diesel engine and the pump unit, minimizing intermediate transmission links in the power output process. This reduces energy loss and mechanical failure points at the source, ensuring stable and reliable performance even under high loads and prolonged operation. The diesel engine, as the core power source, features rapid start-up, high torque output, and strong fuel adaptability. It can independently start and operate even in environments without mains power, with unstable power supply, or complete power outages. This advantage makes diesel engine direct-drive fire pumps crucial equipment in mobile fire protection systems, field firefighting, temporary fire stations, and emergency rescue scenarios. Due to the direct-drive structure, the engine crankshaft’s power is directly transmitted to the pump shaft, avoiding slippage, wear, or loosening problems that occur with belts and couplings during high-speed or long-term use. This not only improves mechanical efficiency but also significantly extends the overall service life of the machine. The pump body is typically made of high-strength cast iron or wear-resistant alloy materials, possessing excellent impact resistance and corrosion resistance. It can adapt to continuous operation under various water quality conditions, including clean water, slightly sediment-laden water, or natural water sources, thus expanding the equipment’s applicability in multiple application scenarios. In terms of performance, this type of diesel fire pump emphasizes stable flow and continuous head output. Through optimized hydraulic model design, the internal flow channels of the pump chamber are made smoother, effectively reducing hydraulic losses and cavitation risks. It can maintain stable pressure even during long-term continuous water supply, meeting the needs of fire pipelines, spray guns, or long-distance water delivery. Addressing the characteristics of mobile fire protection systems—frequent relocation and significant changes in operating conditions—the diesel engine direct-drive fire pump fully considers the compact structure and installation flexibility of the entire unit during the design phase. The engine and pump body have a high degree of integration, occupying little space and facilitating installation on trailers, fire pump trucks, or temporary racks. This enables rapid deployment and is beneficial for transportation and on-site dispatch. Regarding cooling systems, common air-cooled or water-cooled diesel engines can be configured according to different ambient temperatures and usage frequencies to ensure that the engine can maintain a reasonable operating temperature under high temperature or high load conditions, thereby reducing the risk of power attenuation or failure due to overheating. To improve overall reliability, diesel engine direct-drive fire pumps typically employ thickened designs and reinforced processes in key components, such as reinforced pump shafts, wear-resistant mechanical seals, and high-strength bearings. These detailed designs effectively withstand the mechanical shocks caused by frequent start-stop operations and prolonged high-speed operation, ensuring the equipment is readily available in emergency situations. For mobile fire-fighting systems, rapid start-up and ease of operation are equally crucial. Diesel engine direct-drive fire pumps are usually equipped with intuitive control layouts, allowing operators to quickly complete start-up, speed adjustment, and shutdown operations, enabling rapid establishment of water supply capacity even in emergencies, buying valuable time for initial fire suppression or fire control. In terms of fuel systems, diesel power offers significant advantages in storage safety and fuel availability, making it more suitable for long-term storage compared to gasoline. It is also easier to replenish in remote areas, giving diesel fire pumps greater practical value in forest fire prevention, mine fire fighting, construction site fire prevention, and temporary emergency rescue. To meet different fire protection standards and usage requirements, diesel engine direct-drive fire pumps offer strong parameter configuration options. Different combinations of flow rate, head, and speed can be selected based on actual working conditions, adapting to various pipe diameters and fire extinguishing methods. They can be used for direct water supply fire extinguishing or as backup power equipment in fixed or semi-fixed fire protection systems. Regarding long-term maintenance, these fire pumps have a relatively simple structure. Routine maintenance mainly involves routine inspections, oil changes, and filter system maintenance. They do not require complex electrical control systems or high-precision electronic components, lowering the maintenance threshold and operating costs, and maintaining a high cost-performance ratio throughout the equipment’s lifespan. In summary, the high-reliability diesel engine direct-drive fire pump provides a reliable, continuous, and efficient water supply for mobile fire protection systems through its stable power output, robust and durable structural design, and adaptability to various complex working conditions. It can play a key role in sudden fires, natural disaster relief, and temporary fire protection tasks lacking fixed infrastructure. Its performance advantages are not only reflected in the technical parameters, but also in its proven stability and safety in practical applications.