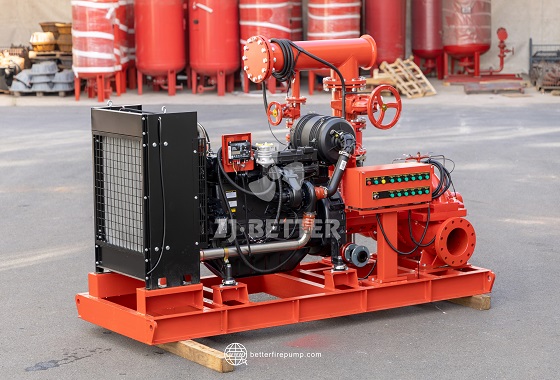

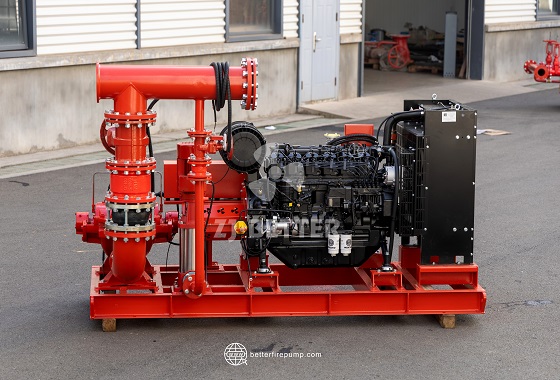

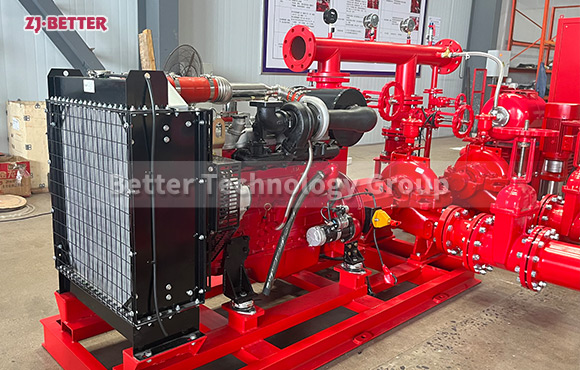

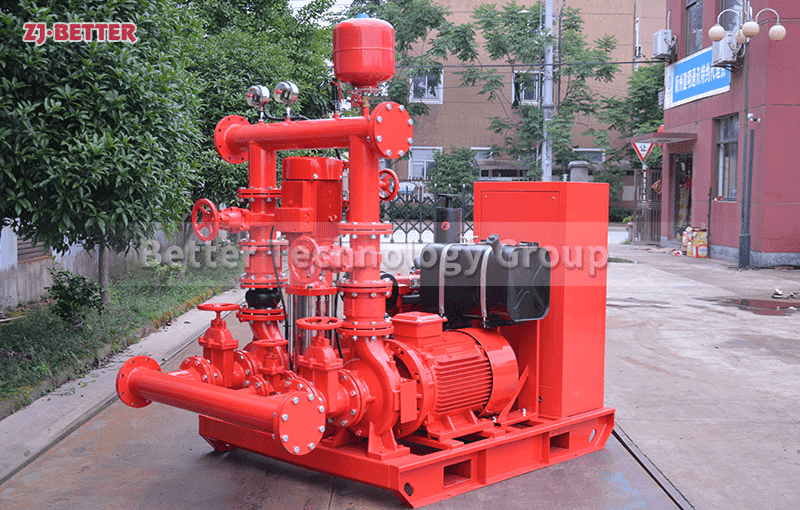

Long-Running High-Temperature Resistant Diesel Fire Pump for Warehouses and Plants

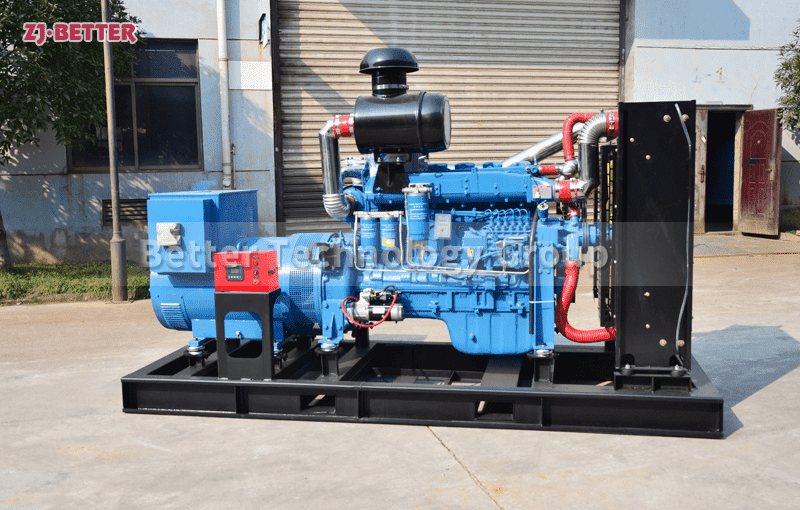

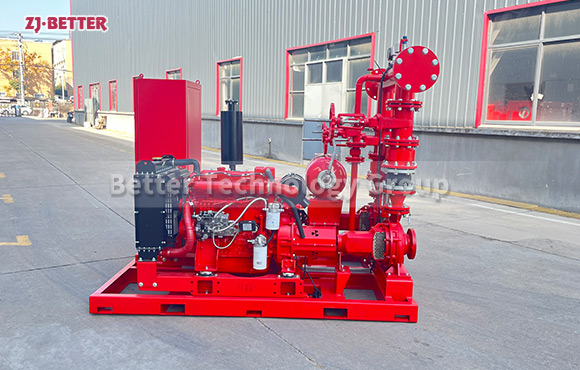

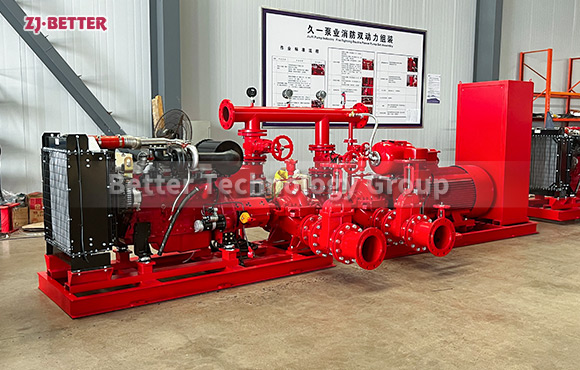

This high-performance diesel fire pump is specifically designed for warehouse and factory fire protection systems. It features high temperature resistance, continuous long-term operation, independent power supply, and stable water delivery capabilities. It reliably starts even in extreme conditions such as power outages, making it suitable for high-risk industrial and warehousing fire protection applications.

In high-fire-risk environments such as warehouses and factories, the reliability of fire protection systems is directly related to personnel safety and property damage control. High-temperature resistant, continuously operating diesel fire pumps are indispensable core equipment in such scenarios. These fire pumps use independent diesel power as their driving source, eliminating reliance on external power systems. Even in extreme situations where a fire causes power outages or system failures, they can quickly start and provide a continuous and stable water supply, ensuring reliable water pressure and flow for the entire fire protection system. The design of this diesel fire pump fully considers the complex operating conditions of warehouse and factory environments, such as high temperatures, high dust levels, high humidity, and the need for instantaneous startup after prolonged standby. The entire unit features a high-strength steel base and an integrated skid-mounted layout, allowing for high integration of the engine, water pump, control system, cooling system, and fuel system. This not only reduces the footprint and allows for flexible installation but also effectively reduces on-site construction difficulties and shortens project delivery time. The core water pump typically utilizes a mature single-stage or multi-stage centrifugal pump structure. Through precise hydraulic model design, the pump maintains high efficiency and stability even under high flow and high head conditions, reducing energy loss while effectively lowering operating vibration and noise, making it particularly suitable for fire protection applications requiring continuous water supply for extended periods. To address the need for high-temperature operation, the diesel fire pump features systematic optimization in material selection and cooling systems. Key components such as the pump casing, impeller, shaft, and shaft seal are made of wear-resistant, corrosion-resistant, and high-temperature resistant materials, ensuring that the equipment maintains good mechanical performance and sealing performance even with high-temperature water sources or continuously rising ambient temperatures, preventing performance degradation due to thermal deformation or material fatigue. The engine is equipped with a high-efficiency radiator and an independent air-cooling or water-cooling system. Through reasonable airflow design and heat dissipation area configuration, the engine can maintain a stable operating temperature even under full load and continuous operation, significantly extending the overall service life. This diesel fire pump also excels in control and protection. The control system integrates multiple functions, including automatic start, automatic switching, operation monitoring, and fault alarm. It can respond quickly upon receiving a fire signal or detecting abnormal pipeline pressure, ensuring that effective water pressure is established immediately in the early stages of a fire. The system also monitors key parameters suchs as oil pressure, water temperature, rotational speed, and battery voltage in real time, issuing alarms or taking protective measures if any abnormalities occur, thus minimizing the risk of equipment failure. In warehousing and factory applications, fires often spread rapidly and burn for extended periods, placing higher demands on the continuous operation capabilities of fire pumps. This diesel fire pump, through optimized fuel supply and lubrication system design, maintains stable output even under prolonged high-load conditions, resulting in more uniform and efficient fuel consumption and reducing the risks associated with frequent shutdowns or refueling. Furthermore, the entire unit typically undergoes rigorous performance and continuous operation testing before leaving the factory, simulating long-term operation under actual fire conditions to ensure sufficient reliability and safety redundancy in real-world applications. For warehouses, logistics centers, production plants, chemical warehouses, and raw material storage yards, this type of diesel fire pump can be used not only as the main fire pump but also as a backup or emergency pump, complementing electric fire pumps to create a more comprehensive fire water supply system. When electricity is available, the electric pump handles daily fire protection needs; in the event of a power outage or extreme circumstances, the diesel pump seamlessly takes over, significantly enhancing the overall system’s safety level. From a maintenance perspective, this diesel fire pump is designed for long-term ease of use. The skid-mounted structure provides a clear layout of components, ample space for daily inspection, maintenance, and parts replacement, reducing maintenance difficulty and labor costs. Standardized interfaces and common parts also make future maintenance more efficient. In summary, the high-temperature resistant, long-running diesel fire pump, with its independent power source, stable performance, strong adaptability, and high reliability, demonstrates significant advantages in warehousing and factory fire protection applications. It can continuously and reliably provide fire water at critical moments, buying valuable time for fire control and personnel evacuation, making it a trustworthy and important piece of equipment in modern industrial and warehousing fire protection systems.