Power-Free Fire Protection with Diesel Engine Fire Pump for Critical Environments

The diesel fire pump system operates independently and does not require a power source. It is suitable for power outages, outdoor areas, and high-risk locations, ensuring uninterrupted fire water supply in critical scenarios and rapid and reliable emergency response.

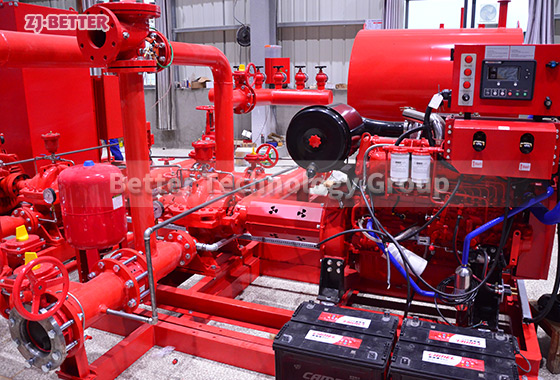

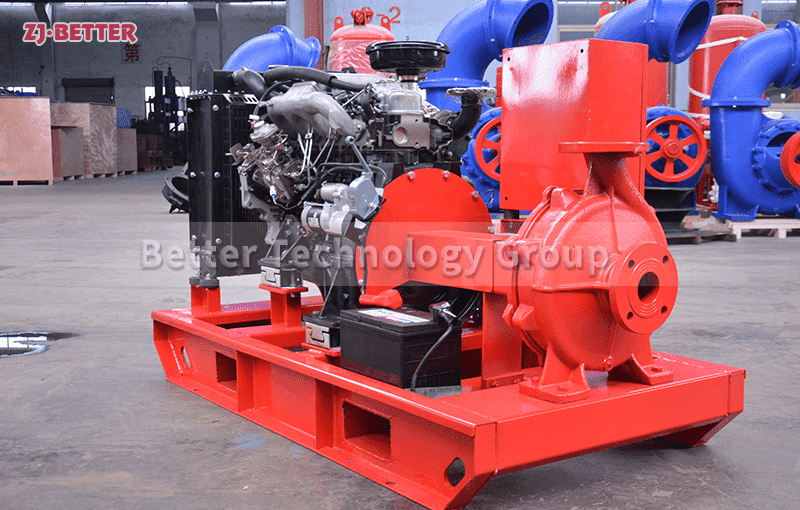

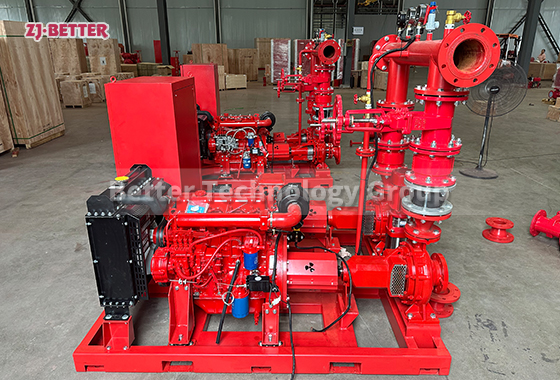

In the construction of fire protection systems for modern buildings, industrial facilities and field projects, unstable power supply or complete power outages are not uncommon, especially in remote areas, areas prone to natural disasters or during the construction phase of large projects, where the municipal power supply system cannot cover or there is a risk of fluctuations. Fires often occur at these most vulnerable moments, so a fire water supply system that does not rely on municipal electricity and has independent driving capabilities is crucial. As an independent water supply equipment completely driven by a diesel engine, the diesel pump system has become the preferred solution for dealing with such complex environments and sudden fires due to its powerful self-starting ability, high stability and strong adaptability to the environment. This type of pump group is mainly composed of an industrial-grade diesel engine, a horizontal centrifugal pump, a high-strength steel structure base, an intelligent control cabinet, a pipe connection system, a battery starting module, a cooling system and a fuel tank. All components are pre-installed on a unified platform to achieve integrated design and integrated operation. It can be deployed in any scenario that requires fire water supply protection without relying on external power or communication networks, truly realizing the fire protection goal of “starting as soon as water is supplied and still being able to operate after power failure”.

From the perspective of structure and configuration, the diesel engine fire pump group uses a high-power output diesel engine as the power source, directly drives the centrifugal pump for water flow transportation, and has strong starting torque and continuous water supply capacity. Compared with electric fire pumps, diesel engines have stronger independence and can start quickly even in a complete power outage, ensuring that sufficient water pressure and flow are provided in the first time, meeting the urgent needs of the fire protection system for water sources in the early stage of fire extinguishing. Its fuel system is equipped with a large-capacity fuel tank, which can support continuous operation for several hours after a single filling, and is suitable for long-term emergency water supply scenarios. The cooling system adopts an air-cooled or water-cooled structure to ensure that the engine maintains a stable operating temperature when running at high loads and prolong the life of the equipment. The exhaust system is equipped with a muffler and a heat shield to effectively reduce operating noise and ensure safe use. It is suitable for installation in densely populated areas or closed pump rooms. The control cabinet has multiple start modes, including manual, electric start, automatic remote start, etc. The system has built-in pressure sensors, oil temperature monitoring, fuel level alarms, automatic preheating devices, regular self-test programs and other functions. When a fire occurs, it can automatically identify signals, start the equipment and keep it running without manual intervention, greatly improving the response speed and emergency efficiency.

In terms of performance, the equipment uses an industrial-grade centrifugal pump, which has the characteristics of high head, large flow, high efficiency, and low mechanical loss. It can stably output large amounts of water and transport water over long distances, ensuring constant pressure in the entire fire protection pipe network system. The pump body is made of high-strength cast iron or stainless steel, and the impeller is dynamically balanced. It runs smoothly and has strong corrosion resistance. It is suitable for various clean water, weakly corrosive liquids or water sources containing a small amount of impurities. The pump shaft and the diesel engine are precisely connected through a high-strength coupling to ensure efficient power transmission and avoid energy loss. The inlet and outlet flanges are standardized, which is easy to connect to the existing pipe network system, facilitate on-site installation or replace the original equipment, and shorten the construction period. In addition, the whole set of equipment has a compact structure and a small footprint. The base has forklift holes and hoisting holes, which are convenient for mobile deployment on construction sites, workshops or in the field. For long-term installation projects, modules such as rain covers, silencers, and heat insulation covers can also be added to improve outdoor adaptability and operational stability.

In practical applications, diesel pump systems are widely used in power plants, oil fields, mines, ports, railways, highway tunnels, oil depots, gas stations, chemical parks, high-rise buildings, airports, temporary camps, rural firefighting and other places, especially in areas where electricity cannot be guaranteed or power supply fluctuates greatly. It can not only be used as the main fire pump, but also as a backup pump to work with the electric pump. When the electric pump fails or the power grid fails, it can start the replacement task in time to ensure uninterrupted water supply of the system. Some projects also use diesel pump systems for auxiliary functions such as pool water replenishment, spray pressure supply, and long-distance dispatch of water delivery to expand its use value. In addition, for field work areas such as construction sites, bridge construction, and temporary road construction, the diesel pump system is more suitable for frequently changing water supply needs due to its characteristics of not relying on the power grid, fast deployment, and flexible control. For smart cities or projects with high requirements for remote monitoring, 4G remote modules or IoT gateways can also be selected to realize functions such as remote viewing of device status, starting equipment, and receiving alarm information on the mobile terminal, which is convenient for unified operation and maintenance management and improves management efficiency.

At the operation and maintenance level, the diesel engine fire pump system also takes into account the user’s convenience. The control system has built-in multiple protection mechanisms, such as overheat protection, low oil pressure alarm, overspeed shutdown, oil shortage power failure, anti-backwater shock and other functions to ensure the safe operation of the equipment. For daily maintenance, you only need to regularly replace the engine oil, air filter, fuel filter, check the battery voltage and wiring status. The maintenance cycle can reach more than 200 hours, and the whole machine has high operating stability. Manufacturers usually provide complete installation manuals, startup operation guides, maintenance flowcharts and video guidance materials, so that new users can also get started quickly. In addition, according to different customer needs, the diesel pump system can also be equipped with dual pump switching, two-unit linkage, one standby and one use, one main and multiple standby operation modes, further improving the system redundancy and flexibility of use. For engineering projects with multiple devices running in coordination, the system also supports intelligent management functions such as grid-connected operation, pressure linkage control, and zoned water supply to help users build an efficient, safe and reliable fire water supply system.

In summary, as an important equipment in the field of modern emergency water supply, the diesel pump fire fighting system plays an irreplaceable and important role in various high-risk and high-demand scenarios with its significant advantages of “independent of power supply, autonomous water supply, rapid start-up, compact structure, and wide application”. It provides stable fire protection for areas with unstable power supply, flexible water supply support for outdoor and temporary places, and also brings a higher level of safety protection capabilities to various construction projects and industrial projects. With the continuous advancement of urbanization and infrastructure construction, the demand for flexible, stable, and intelligent fire water supply systems will continue to grow. The diesel pump system will undoubtedly occupy an increasingly important position in the future application of fire fighting equipment and is one of the core equipment worthy of investment and trust in various projects.