Efficient Electric Fire Pump Solution for Parking Garages and Small Factories

Vertical electric fire pumps are small in size and highly efficient. They are suitable for underground garages and small factories. They are easy to install and operate stably. They are an ideal choice for fire protection systems in small and medium-sized buildings.

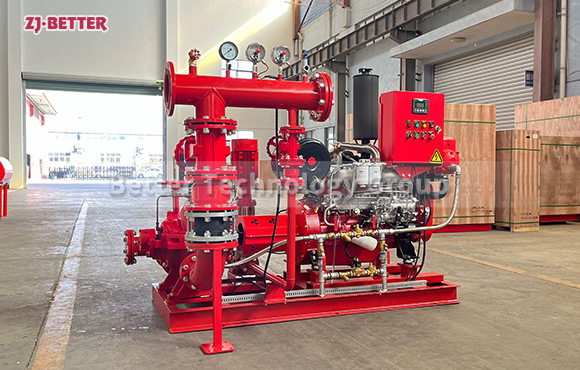

In modern urban building planning and industrial development, more and more projects are facing multiple challenges such as tight space, concentrated power supply, and short construction period, especially in underground garages, small factories, commercial stores, equipment rooms and other environments, which put forward higher requirements on the volume, installation flexibility and operation stability of fire-fighting equipment. In this context, vertical electric fire pumps, as a water supply equipment with compact structure, high efficiency and rapid start-up, have gradually become the preferred solution for various small and medium-sized fire-fighting systems. This type of equipment generally uses a vertical multi-stage centrifugal pump as the core power, with a high-efficiency motor drive, and integrates control cabinets, pressure gauges, check valves, electronic control pipeline systems, base platforms and other components. It is pre-assembled and shipped without on-site welding and complex debugging. It is especially suitable for construction sites with limited space, high frequency of use and high requirements for maintenance convenience, such as underground parking lots, light factories, small office buildings, warehouses, supermarkets and residential fire-fighting pipe networks, which can effectively achieve the goals of rapid water supply, automatic start-up, low noise operation and intelligent control.

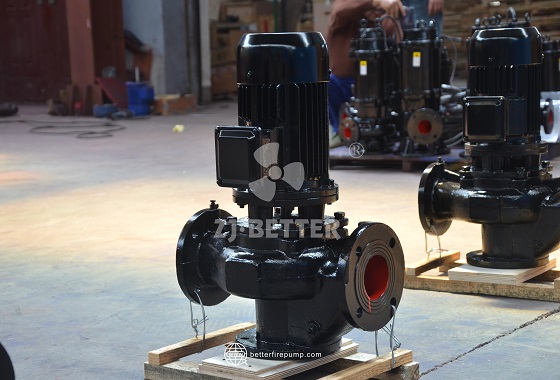

The significant advantage of vertical electric fire pumps is that their structural layout is optimized and they occupy a small area. Since the pump body and the motor adopt a coaxial vertical structure, the overall height is high but the lateral size is extremely small, which is suitable for installation in special places such as equipment rooms, stairwells, basements, and narrow pump rooms. At the same time, its inlet and outlet flanges are usually located on the same center line, which simplifies the on-site pipeline installation layout and reduces the use of pipeline elbows and connectors, thereby reducing installation costs and pipe loss. In equipment-concentrated areas such as small factories or underground garages, this vertical structure is easier to integrate with existing building spaces to achieve compact layout and efficient operation. For developers and fire engineering contractors, it means lower civil engineering renovation pressure and higher design flexibility.

In terms of performance, vertical multi-stage centrifugal pumps have the characteristics of high head, low flow loss, and smooth operation. Its multi-stage impeller series design can easily cope with high-rise and multi-branch fire pipeline systems, ensuring that each outlet can obtain stable water pressure. Compared with traditional horizontal pumps, the vertical structure is more suitable for long-term continuous operation of fire emergency conditions due to its balanced axial force distribution, small vibration, and longer bearing life. In addition, this type of electric fire pump usually uses a high-efficiency, low-energy copper wire motor, which starts quickly and has sufficient power. The motor protection level is generally IP54 and above, and it has good dust and water resistance. It can maintain long-term stable operation in an underground environment with high humidity.

In terms of control, the electronic control system of the equipment generally adopts an integrated control cabinet design, with preset functions such as automatic/manual start, pressure detection, overload protection, phase loss alarm, and fault shutdown. Some systems support linkage with the building fire alarm system, which can automatically start the water pump within 5 seconds after the fire alarm signal is issued, providing instant water source response to ensure the initial fire extinguishing needs. The control cabinet shell is made of plastic-sprayed steel plate, which is sturdy and corrosion-resistant. It is equipped with ventilation holes and waterproof sealing strips to effectively resist the intrusion of underground environmental factors such as moisture and dust. In order to improve operation and maintenance efficiency, the control system can also expand the remote monitoring module, and realize remote start, status query, alarm push and other functions through RS485 or 4G Internet of Things communication. It is suitable for the centralized management needs of intelligent building systems and helps property units realize unmanned and automatic inspection modern operation mode.

From the perspective of installation and maintenance, vertical electric fire pumps have obvious modular and humanized characteristics. The whole machine is assembled and tested before leaving the factory. After arrival, it only needs to be connected to the power supply and pipeline to use, which greatly shortens the construction period. The base of the equipment has reserved bolt holes and forklift holes, which is convenient for hoisting and positioning at the construction site. In terms of maintenance, it is only necessary to regularly check the motor insulation, electronic control circuit, pump shaft lubrication and sealing performance, without disassembling the machine for cleaning, which reduces the cost and frequency of manual maintenance. Some products are also designed with easy-to-disassemble couplings and quick-disassembly pump covers, which are convenient for internal inspection or replacement of wearing parts without removing the pipeline, greatly improving the convenience of later use of the equipment.

In terms of scope of application, the vertical electric fire pump group is highly versatile and widely adaptable. For underground garages, the pump group can be arranged in a narrow equipment well or water tank room, meeting the basic requirements of the “Building Design Fire Protection Code” for fire water supply flow and pressure, and at the same time has the advantages of low noise and fast start-up, avoiding affecting residents’ daily life. In small factory scenes, the equipment is small in size and stable in operation. It effectively cooperates with indoor sprinkler systems, fire hydrant systems and other water supply networks to achieve all-weather standby operation. In commercial projects such as office buildings, shops, and underground commercial complexes, vertical electric fire pumps are also widely adopted for their simple appearance, quick response, and easy operation, becoming one of the mainstream models recommended by fire construction units.

In addition, to meet the needs of different projects, this series of pumps can also be customized according to customer requirements for different flow rates, lifts, voltage frequencies, connection flange standards, and control functions. Some products support advanced solutions such as dual pump parallel operation, one standby and one use switching, and constant pressure frequency conversion control, helping users achieve higher levels of system optimization in terms of energy saving, stability, and redundancy. At the same time, for special environments such as high temperature, high humidity, and high corrosion, stainless steel pump bodies, high temperature resistant sealing rings, explosion-proof motors and other components can be selected to enhance the environmental adaptability and service life of the entire machine, and meet the use standards of various complex engineering conditions.

In summary, vertical electric fire pump units have become one of the most cost-effective and practical solutions in the current fire protection systems of small and medium-sized buildings due to their comprehensive advantages such as compact structure, efficient operation, intelligent control, convenient installation, and simple maintenance. It not only meets the urgent needs of typical application scenarios such as underground garages and small factories for miniaturization and intelligence of equipment, but also conforms to the overall development trend of modern urban buildings for efficient, green, and safe fire protection facilities. With the acceleration of urban renewal and the increase in the popularity of smart buildings, the demand for this type of high-performance, small-volume fire pump equipment will continue to rise, and the future market potential is huge, which deserves the focus and extensive promotion of engineering contractors, equipment purchasers, and property units.