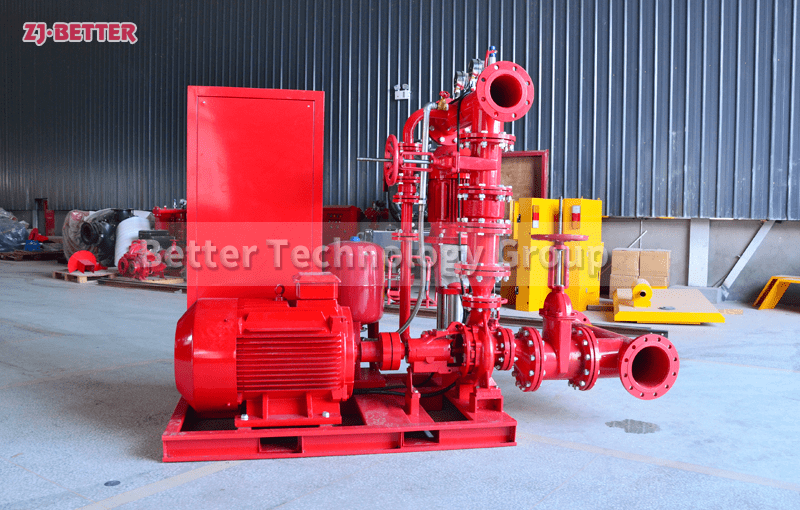

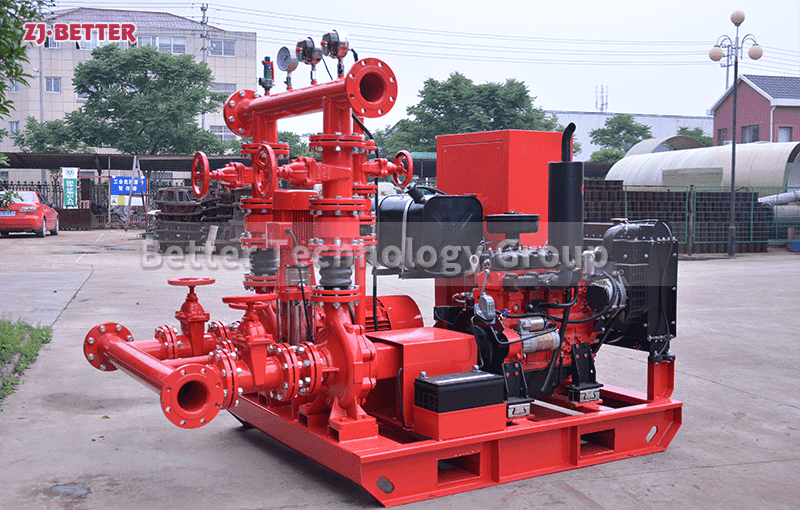

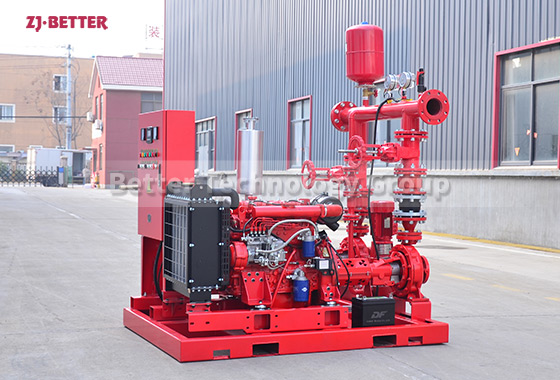

Standard EDJ Multistage Fire Pump

EDJ multi-stage fire pump consists of electric pump, diesel engine pump and jockey pump. The electric pump is the working pump, and the diesel engine is the backup. The more impellers used in the multi-stage electric pump, the higher the lift. This product can run in the event of a power failure and is suitable for any emergency firefighting occasions, mainly used for the top of high-rise buildings or towers water supply, etc.

The multiple impellers of a multi-stage electric fire pump are all mounted on the same shaft and rotate, essentially acting like individual pumps. This means that as flow flows from one stage to the next, the head increases by about the same amount, resulting in a multistage pump design with a higher pressure capacity than a single impeller alone, suitable for high flow, low pressure applications, primarily for high-rise applications The multi-stage fire pump has the characteristics of high efficiency, low energy consumption, reasonable structure and beautiful appearance.