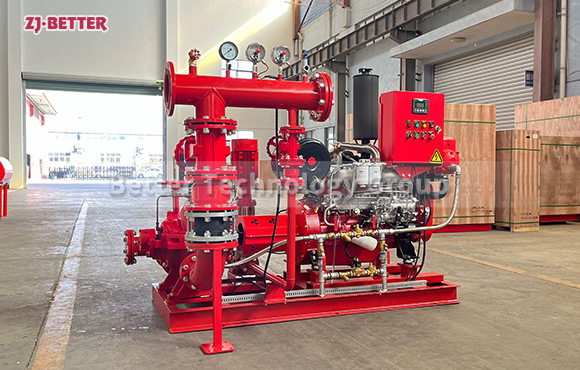

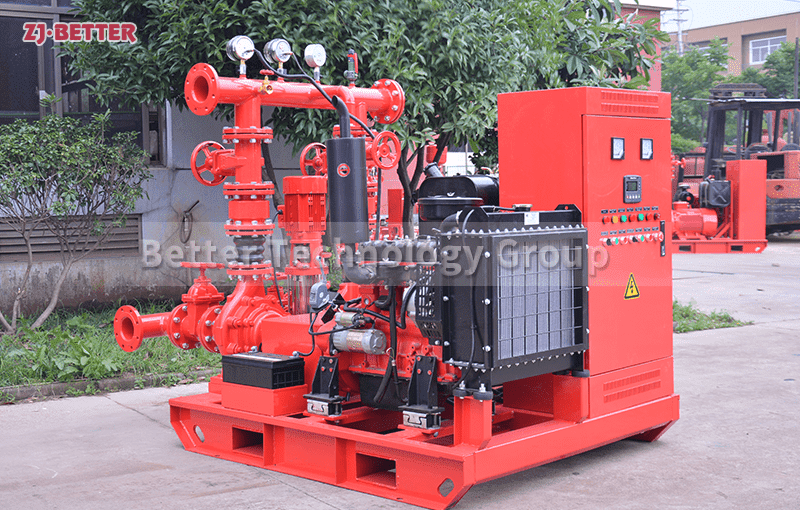

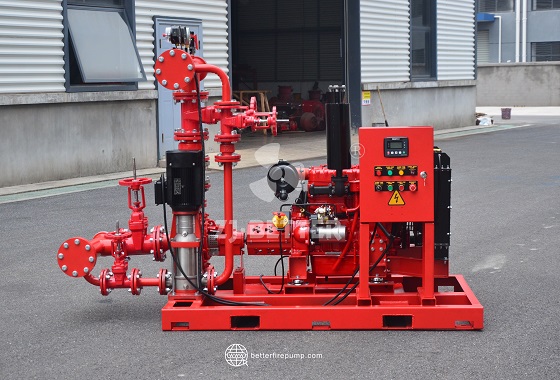

Automatic Control Fire Pump Unit: Smart Operation Ensuring Fire Safety

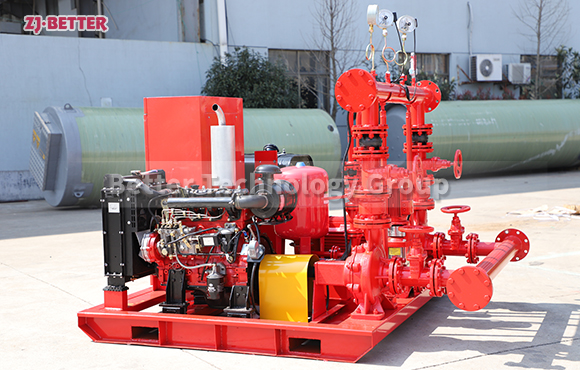

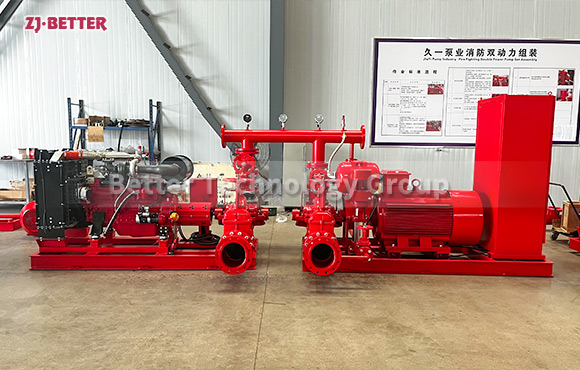

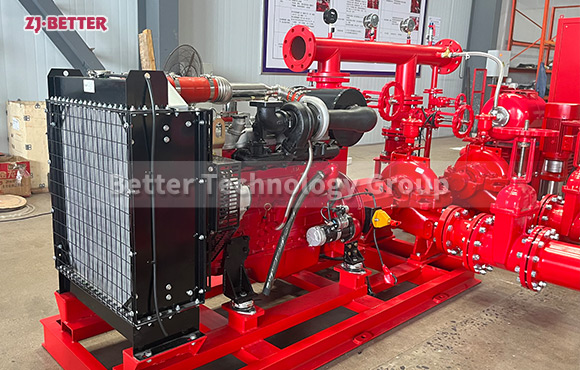

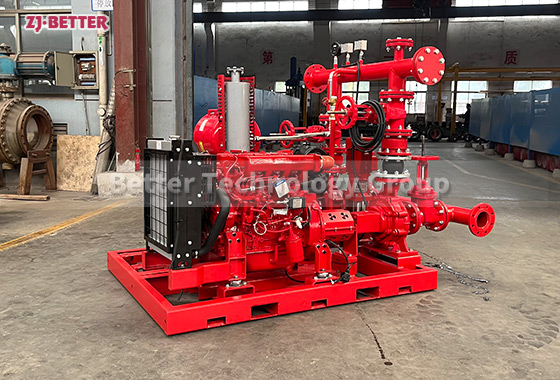

Automatically control the fire pump group, integrate intelligent monitoring, automatic start and stop, and standby switching to ensure rapid fire emergency response, stable water supply, high efficiency and energy saving, and easy installation and maintenance.

Fire safety has long been a crucial aspect of modern buildings and industrial facilities. With the continuous expansion of building scale and the increasing complexity of fire risks, traditional fire pump systems that rely on manual activation or control are no longer able to meet the real-time and stability requirements. Against this backdrop, automatic fire pump systems have emerged. Leveraging advanced intelligent control technology and stable and reliable power output, they have become essential core equipment for ensuring building fire safety and improving emergency response efficiency. These pump systems are widely used in high-rise buildings, residential communities, industrial plants, warehouses and logistics centers, and petrochemical plants. They are also considered essential safety barriers in critical locations such as airports, train stations, ports, and power systems. The design concept of automatic fire pump systems seamlessly integrates the pump, drive unit, electronic control system, pressure monitoring, alarm feedback, and backup power, enabling intelligent management of the entire process from startup, operation, and shutdown. In the immediate event of a fire, when the pipeline pressure drops to a set value, the system automatically initiates a start command, ensuring the fire pumps quickly enter operation and providing stable and sufficient water pressure to support the fire sprinkler system, fire hydrant system, and other fire extinguishing devices. This automatic response, requiring no human intervention, significantly improves the efficiency of initial firefighting and avoids significant losses caused by operational delays. Compared to traditional fire pump sets, automatic fire pump sets offer significant advantages in operational stability and reliability. Their modular electronic control system integrates a PLC logic controller, pressure sensors, current detectors, and voltage monitoring devices. This system monitors system status in real time, instantly triggering audible and visual alarms in the event of an anomaly, and even automatically switches to a backup pump. This multi-faceted protection mechanism ensures that the fire pump will not be paralyzed by a single point of failure at critical moments, truly embodying the high-reliability design philosophy. Furthermore, the automatic control system features a self-test function that allows for regular, short test runs of the pump set to ensure optimal readiness. In terms of performance, the automatic fire pump set utilizes an energy-efficient hydraulic model. The impeller and pump body are precision-machined and dynamically balanced, ensuring high hydraulic efficiency and low vibration during operation. The pumps can be driven by either an electric motor or a diesel engine to suit the power conditions and usage requirements of different locations. Electric motor-driven pumps offer a fast response time and are suitable for buildings and factories with stable power supplies. Diesel-driven pumps, on the other hand, remain stable during power outages or interruptions, providing robust emergency response. Furthermore, some automated fire pumps support dual-power switching between electric and diesel, seamlessly facilitating backup power in the event of a primary power failure, further enhancing system redundancy and safety. These pumps also offer significant advantages in energy conservation and environmental protection. Intelligent variable frequency speed control technology automatically adjusts the pump speed based on the real-time needs of the fire protection network, avoiding inefficient high-load operation and significantly reducing energy consumption. Furthermore, this flexible start-up and shutdown mechanism effectively reduces inrush current and mechanical wear on the motor, extending the equipment’s lifespan. For locations that routinely balance water supply and firefighting, this intelligent adjustment capability not only saves operating costs but also ensures the system’s multifunctional application value. In terms of installation and maintenance, the automatic fire pump unit features an integrated structure and is fully commissioned before leaving the factory. Users only need to connect the piping and power supply for immediate operation, significantly reducing installation time and costs. The intuitive control panel, equipped with an LCD screen or indicator lights, displays the pump unit’s operating status, pressure readings, and fault information in real time, allowing operators to quickly understand equipment conditions. During routine maintenance, the system automatically records an operation log, enabling technicians to analyze operating data, identify potential hazards, and conduct preventive maintenance. This data-driven management approach is more efficient and effective than traditional manual inspections. Notably, the automatic fire pump unit also supports remote monitoring and networking. By integrating with building automation systems and smart fire protection platforms, managers can monitor equipment operation in real time from a monitoring center or mobile device, and even remotely start, stop, and adjust parameters. This functionality is particularly important for large campuses, multi-regional management, and unmanned locations. It not only improves management efficiency but also makes fire protection system operation more intelligent and visual. Regarding safety, the automatic fire pump unit undergoes rigorous performance and quality testing and complies with domestic and international fire protection standards and industry regulations. Its pressure resistance, flow range, head coverage, and operational stability all meet the design requirements of various locations. The pump body, constructed of high-strength cast iron or stainless steel, offers excellent corrosion and wear resistance, enabling long-term operation without damage in complex water conditions. Combined with the highly durable seals and high-load-bearing bearings, the overall structure ensures reliable performance even under intense operation. Overall, the automatic fire pump set is not only a high-performance firefighting device but also an intelligent, systematic safety solution. Its diverse features, including automatic monitoring, automatic start and stop, fault alarm, standby switching, and remote monitoring, elevate fire safety to a new level. For modern buildings and industrial facilities, choosing this pump set not only improves fire emergency response speed but also represents a positive step towards smart firefighting and green energy conservation. Its high reliability, low energy consumption, ease of operation, and scalability make it a popular and increasingly popular core firefighting device in the market. As the firefighting industry continues to pursue intelligence and high efficiency, automatic fire pump sets will play an even more important role in future firefighting system development, truly becoming a solid barrier to protect life and property.