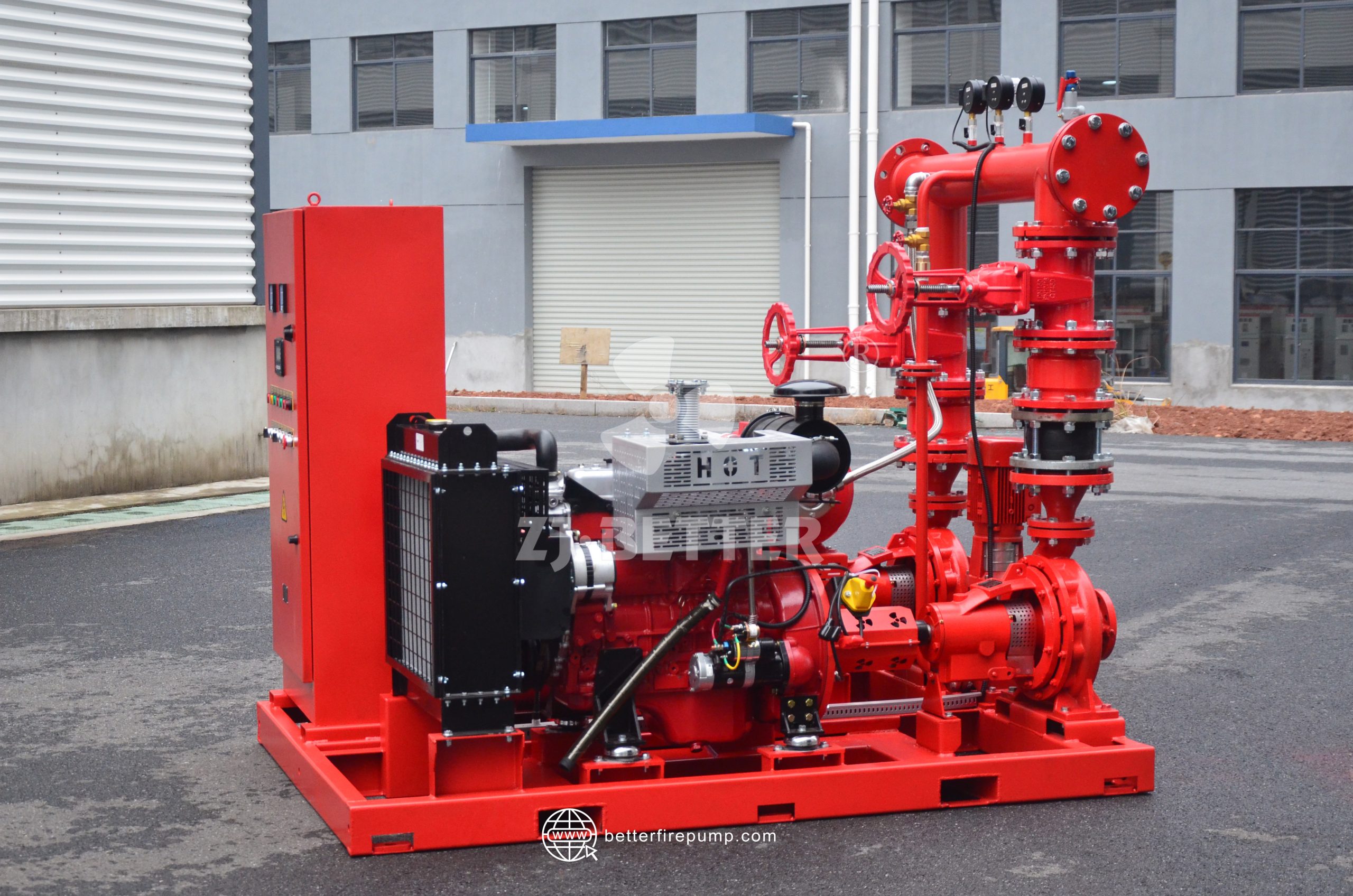

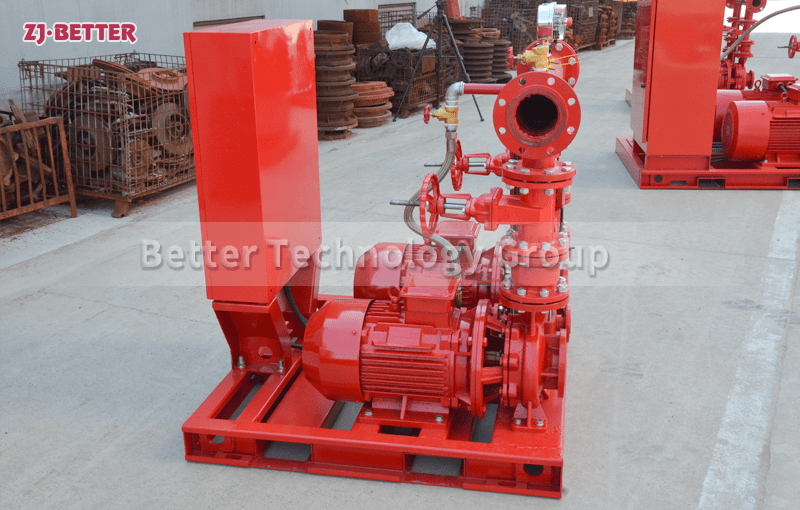

Dedicated Motor for Fire Water Supply Systems Ensuring Rapid Emergency Response

This high-reliability motor for fire-fighting water supply systems features high starting torque, rapid response, high-temperature insulation, and stable continuous operation. It is suitable for various fire pump systems, ensuring continuous and stable water supply in emergency situations and enhancing overall fire safety capabilities.

The dedicated motor for fire-fighting water supply systems is a crucial power core in the entire fire pump system. Its design purpose is to ensure that the pump unit can start immediately and continuously and stably output the required power in emergency situations such as sudden fires, thus providing reliable water supply support for the fire-fighting water supply system. This type of motor fully considers the special characteristics of fire-fighting conditions, and has undergone targeted optimization in terms of structural strength, electrical performance, starting characteristics, and long-term operational stability. Compared with ordinary industrial motors, it places greater emphasis on emergency response capabilities and reliable operation in extreme environments. Firstly, in terms of starting performance, the dedicated motor for fire-fighting water supply systems adopts a high starting torque design. Even under high pipeline pressure and heavy pump load, it can complete the starting process in a very short time, avoiding delays in fire extinguishing due to slow starting. This is particularly critical in application scenarios with complex fire-fighting water supply pressures, such as high-rise buildings, underground spaces, and large factories. The motor windings use high-temperature resistant insulation materials, capable of withstanding frequent starts and instantaneous current surges, ensuring stable performance even after multiple start-stop cycles in emergency situations, and preventing service life from being affected by coil overheating or insulation aging. Secondly, regarding operational stability, this motor is specifically designed for the characteristics of fire protection systems: “standby during normal times and long-term operation during emergencies.” The bearing system utilizes a highly reliable structure and a reasonable lubrication method, allowing for prolonged operation under continuous full load without abnormal wear or excessive temperature rise. This ensures a continuous and stable water supply from the fire pump during firefighting, preventing serious consequences due to power interruption. The motor rotor undergoes precise dynamic balancing, effectively reducing operational vibration and noise. This improves overall operational stability and reduces additional impact on the pump body and piping system, extending the service life of the entire fire water supply system. In terms of environmental adaptability, the dedicated motor for fire water supply systems has a robust casing structure and high protection level, enabling it to adapt to humid, dusty, high-temperature, or poorly ventilated machine room environments. Key internal components undergo anti-corrosion and anti-rust treatment, maintaining stable performance even in coastal areas, high-humidity regions, or industrially polluted environments, and is less prone to performance degradation due to environmental factors. Meanwhile, these motors are designed with compatibility with fire pumps in mind. Their output power, speed range, and efficiency curves are highly compatible with common fire pump models, effectively improving the hydraulic efficiency of the entire pump set and reducing energy loss. While ensuring emergency water supply capacity, they also help reduce ineffective power consumption during system operation. In terms of safety, the dedicated motors for fire water supply systems have multiple safety redundancies in their electrical design, supporting seamless integration with fire control systems. They can work with pressure switches, level signals, and control cabinets to achieve automatic start/stop and status monitoring, ensuring reliable operation even in unattended or emergency situations, truly achieving “always ready to start when needed.” Furthermore, the motor’s structural design facilitates daily inspection and maintenance. The rational layout of key components allows maintenance personnel to complete routine checks without disassembling complex parts, effectively reducing later maintenance costs while improving the long-term controllability and safety of the system. In summary, dedicated motors for fire water supply systems, with their rapid start-up performance, stable and long-lasting operation, excellent environmental adaptability, and design concept that is highly matched to the working conditions of fire pumps, provide a solid and reliable power guarantee for fire water supply systems at critical moments. They are an indispensable and important component in various building fire protection, industrial fire protection, and municipal fire protection projects. Their performance advantages are not only reflected in technical parameters, but also in their powerful protection of life and property safety in real fire scenarios.

.jpg)