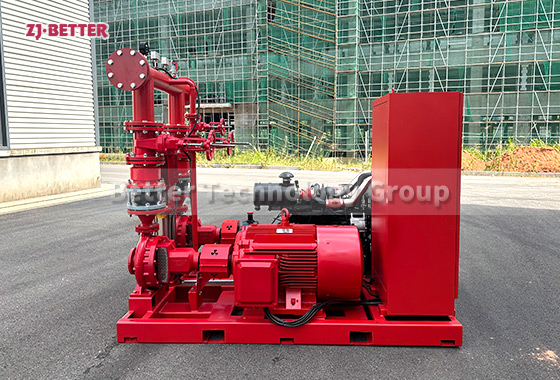

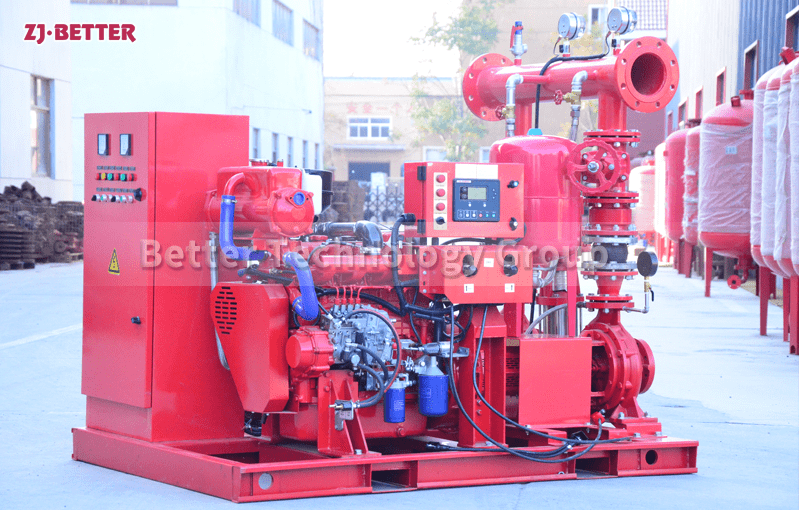

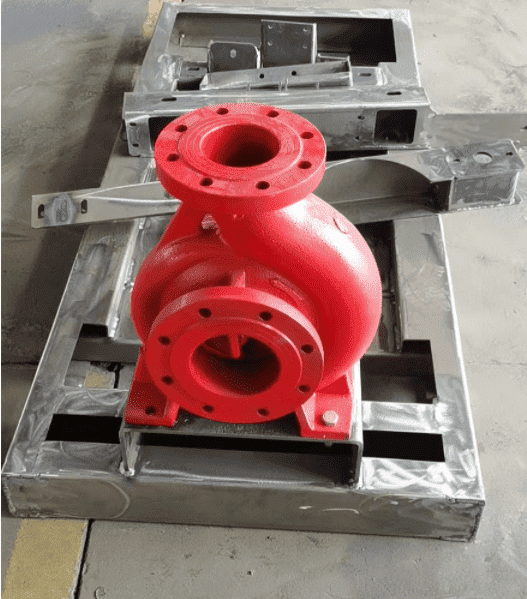

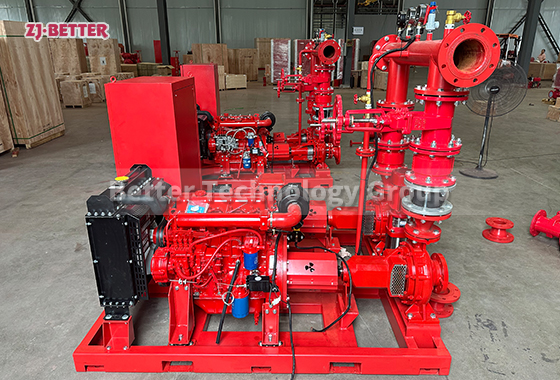

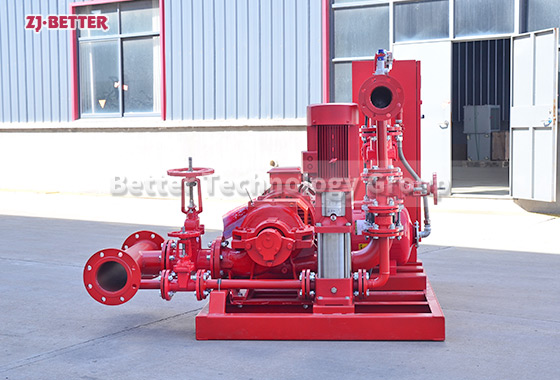

As modern safety standards for large-scale buildings and industrial facilities become increasingly stringent, selecting a highly efficient and reliable fire pump has become a key part of engineering design and construction. The horizontal split case double suction fire pump, with its unique structure, superior hydraulic performance, and exceptional operational stability, is quickly emerging as the top choice for demanding applications. The ZJ-BETTER brand double suction fire pump integrates advanced technologies and precision manufacturing processes, proving highly adaptable in complex operating environments, making it a critical core device for safeguarding vital infrastructure. This pump features a horizontal split case structure, allowing the casing to be opened along the horizontal centerline. This design facilitates easy maintenance without the need to disassemble piping or motors, significantly reducing downtime and enhancing operational efficiency. It is especially suitable for high-demand environments such as airports, subways, high-rise buildings, power plants, and chemical facilities. Internally, the pump adopts a double suction impeller that effectively balances axial forces on the shaft, improving operational stability and reducing bearing loads. This design extends the pump’s service life and provides high flow output at low rotational speeds, thereby reducing noise and vibration levels — a perfect combination of performance and comfort. ZJ-BETTER manufactures this pump under strict ISO9001 quality standards and has obtained CCCf certification, national fire product accreditation, and various high-efficiency energy-saving certifications. The pump’s materials can be customized — including ductile iron, stainless steel, or bronze — to meet specific media and corrosion resistance requirements, greatly expanding its range of applications. The motor can be configured with explosion-proof options and IP55+ protection, F-class insulation, and features such as quick start-up, low energy consumption, and strong overload capacity. It supports intelligent variable frequency drive (VFD) systems for constant pressure water supply and energy-efficient management. For enhanced user experience, ZJ-BETTER equips the pump with intelligent control panels offering automatic start/stop, fault alarms, real-time monitoring, and remote control capabilities. It is compatible with various firefighting systems such as sprinklers, hydrants, water curtains, and combined systems. Diesel engine and electric motor dual-drive options ensure continued operation during power outages. In terms of sealing, the pump uses high-strength mechanical seals made from wear-resistant, corrosion-proof, and high-temperature resistant materials, preventing leakage and ensuring stable performance even when pumping clean water, seawater, or neutral industrial fluids. The shaft is crafted from high-strength alloy steel and undergoes precision machining and dynamic balancing for high rigidity and fatigue resistance, ensuring long-term reliability even under heavy-duty or frequent start-stop conditions. During R&D, ZJ-BETTER employs CFD (Computational Fluid Dynamics) simulation technology to optimize hydraulic components, resulting in high hydraulic efficiency (over 89%) and reduced energy loss — significantly lowering operating costs. The pump’s compact footprint makes it suitable for installations in constrained environments such as mechanical rooms and basements. The symmetrical layout of suction and discharge ports simplifies system integration and supports various flange standards for domestic and international projects. ZJ-BETTER also offers end-to-end services from project planning, model selection, and installation guidance to maintenance and spare parts supply, ensuring long-term support and system stability throughout the pump’s lifecycle. With a customer base spanning more than 30 countries and regions, it is widely used in real estate, transportation, energy, municipal, and industrial sectors. In alignment with global energy-saving and carbon-reduction policies, the pump utilizes efficient hydraulic designs and energy-saving motors, making it a top choice for green buildings and LEED-certified projects. As fire protection systems move toward greater intelligence, automation, and integration, ZJ-BETTER continues to lead the way by combining pump hardware with digital control platforms. Features like big data analysis, cloud-based monitoring, and remote dispatch provide clients with comprehensive smart fire protection solutions, transforming pumps into intelligent nodes within safety systems. In conclusion, the ZJ-BETTER horizontal split case double suction fire pump stands out with its high capacity, efficiency, low noise, and structural reliability. It reflects not only excellence in craftsmanship but also a deep understanding of user needs — delivering safe, efficient, and energy-saving fire pump solutions that help build a stronger global fire safety infrastructure.